Two-step heat press-forging molding method of magnesium alloy thin-wall element and molding die

A technology for forming molds and magnesium alloys, which is applied in the manufacture of tools, metal processing equipment, forging/pressing/hammer devices, etc., can solve the problems of high surface quality, high pressure forging and good formability of magnesium alloy notebook casings, etc. Achieve high product surface quality, good fluidity, and reduce the effect of punching and forging forming pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

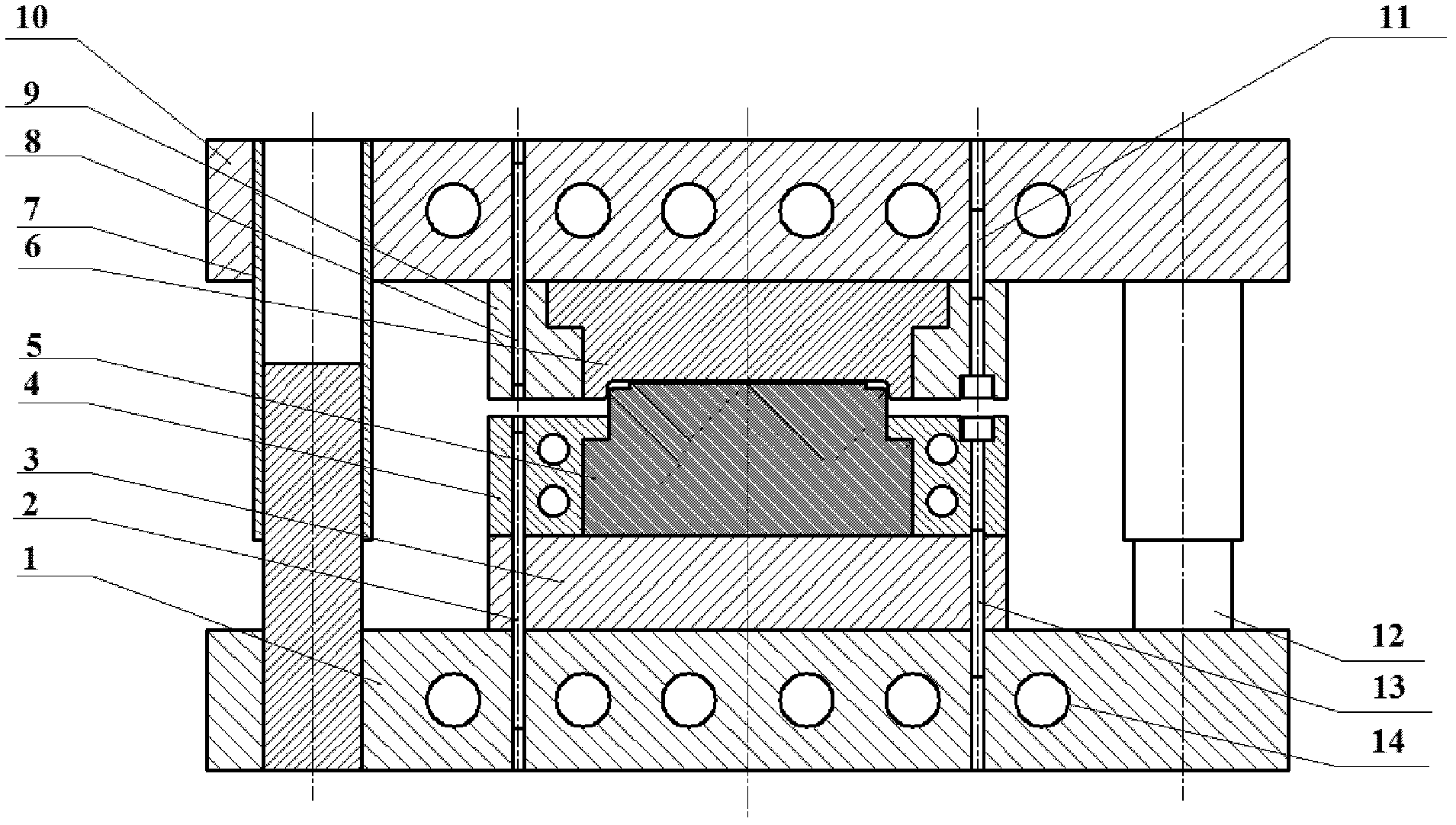

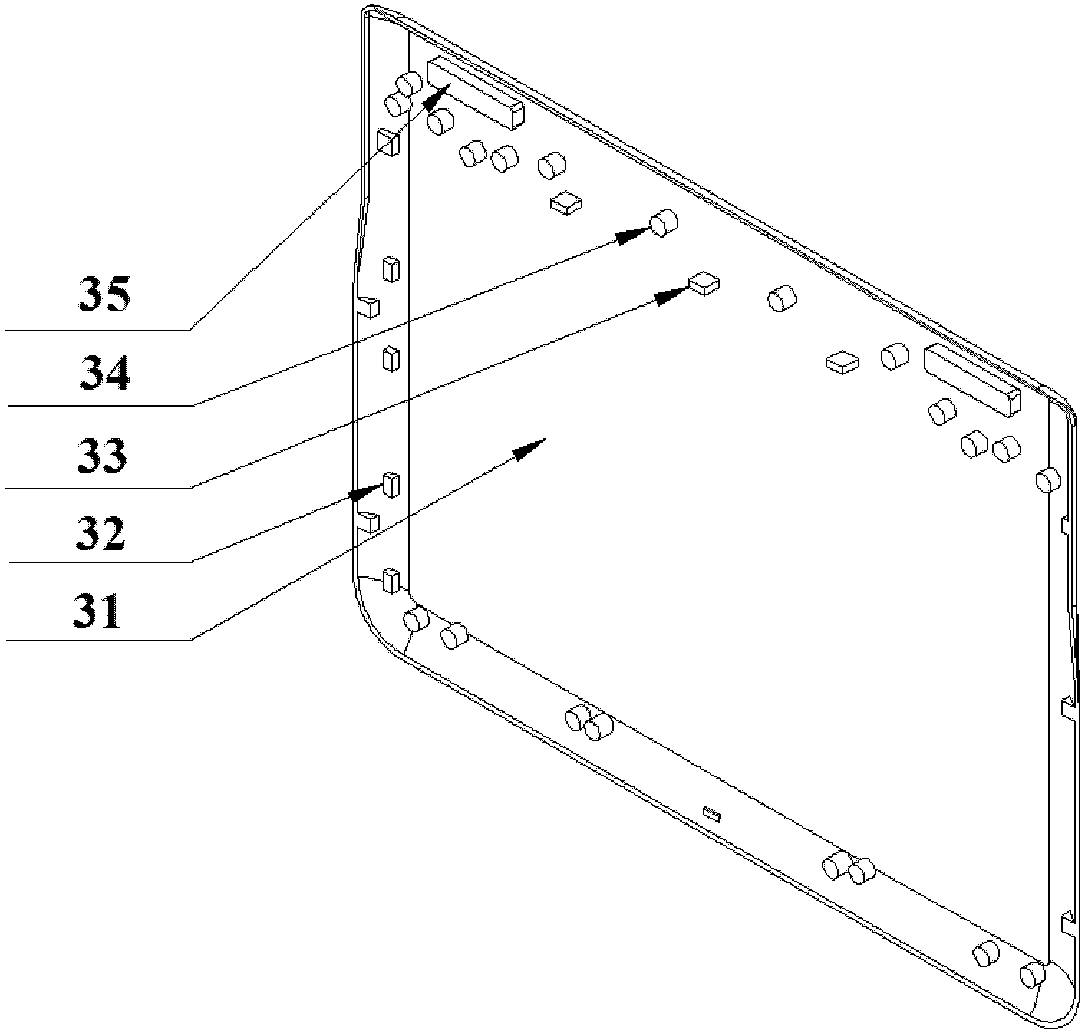

[0053] Two-step stamping and forging is adopted, and the initial stamping and forging gathers materials for local complex structures to form a predetermined semi-finished notebook case, and finally forms the notebook case by stamping and forging. In this embodiment, the two-step hot stamping and forging forming method of magnesium alloy (AZ31) thin-walled parts includes the following steps:

[0054] A piece of 235mm×180mm magnesium alloy sheet is obtained by wire cutting, and its thickness is 2-3mm. The surface of the blank is polished with 1000# sandpaper to make the surface roughness Ra0.32 microns, and the surface is wiped off. Then put it into the box Heating to 380°C in a resistance furnace, holding time for 8 minutes, to avoid the growth of magnesium alloy grains, resulting in the decline of its punching and forging performance.

[0055] First use the preliminary forging die, heat the die to 320°C, at this time the convex and concave dies are in a closed state, when the ...

Embodiment 2

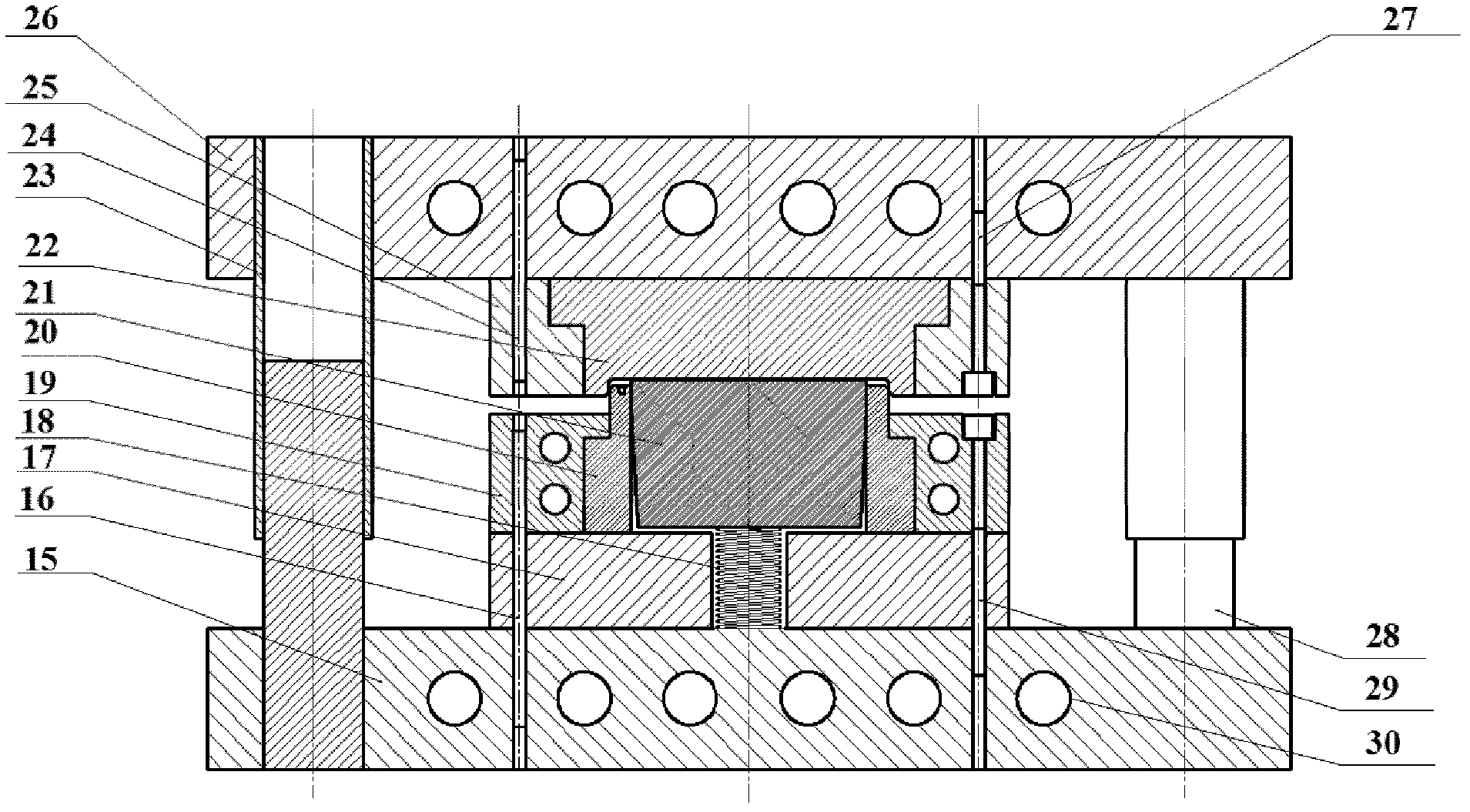

[0059] Two-step stamping and forging is adopted, and the initial stamping and forging gathers materials for local complex structures to form a predetermined semi-finished notebook case, and finally forms the notebook case by stamping and forging. In this embodiment, the two-step hot stamping and forging forming method of magnesium alloy (AZ31) thin-walled parts includes the following steps:

[0060] A piece of 235mm×180mm magnesium alloy sheet is obtained by wire cutting, and its thickness is 2-3mm. The surface of the blank is polished with 1000# sandpaper to make the surface roughness Ra0.32 microns, and the surface is wiped off. Then put it into the box Heating to 350°C in a resistance furnace, holding time for 10 minutes, to avoid the grain growth of the magnesium alloy, resulting in a decrease in its punching and forging performance.

[0061] First use the preliminary forging die and heat the die to 300°C. At this time, the convex and concave dies are in a closed state. Wh...

Embodiment 3

[0065] Two-step stamping and forging is adopted, and the initial stamping and forging gathers materials for local complex structures to form a predetermined semi-finished notebook case, and finally forms the notebook case by stamping and forging. In this embodiment, the two-step hot stamping and forging forming method of magnesium alloy (AZ31) thin-walled parts includes the following steps:

[0066] A piece of 235mm×180mm magnesium alloy sheet is obtained by wire cutting, and its thickness is 2-3mm. The surface of the blank is polished with 1000# sandpaper to make the surface roughness Ra0.32 microns, and the surface is wiped off. Then put it into the box Heating to 400°C in a resistance furnace, holding time for 5 minutes, to avoid the grain growth of the magnesium alloy, resulting in a decrease in its punching and forging performance.

[0067] First use the preliminary forging die, heat the die to 350°C, at this time the convex and concave dies are in a closed state, when th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com