Corrugation pipe cutting machine

A technology of pipe cutting machine and corrugation, applied in the field of corrugated pipe cutting machine, can solve the problems of tool post guidance, inaccurate positioning, feeding length error, inaccurate feeding, etc., to achieve uniform force, small feeding length error, tool post accurate positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

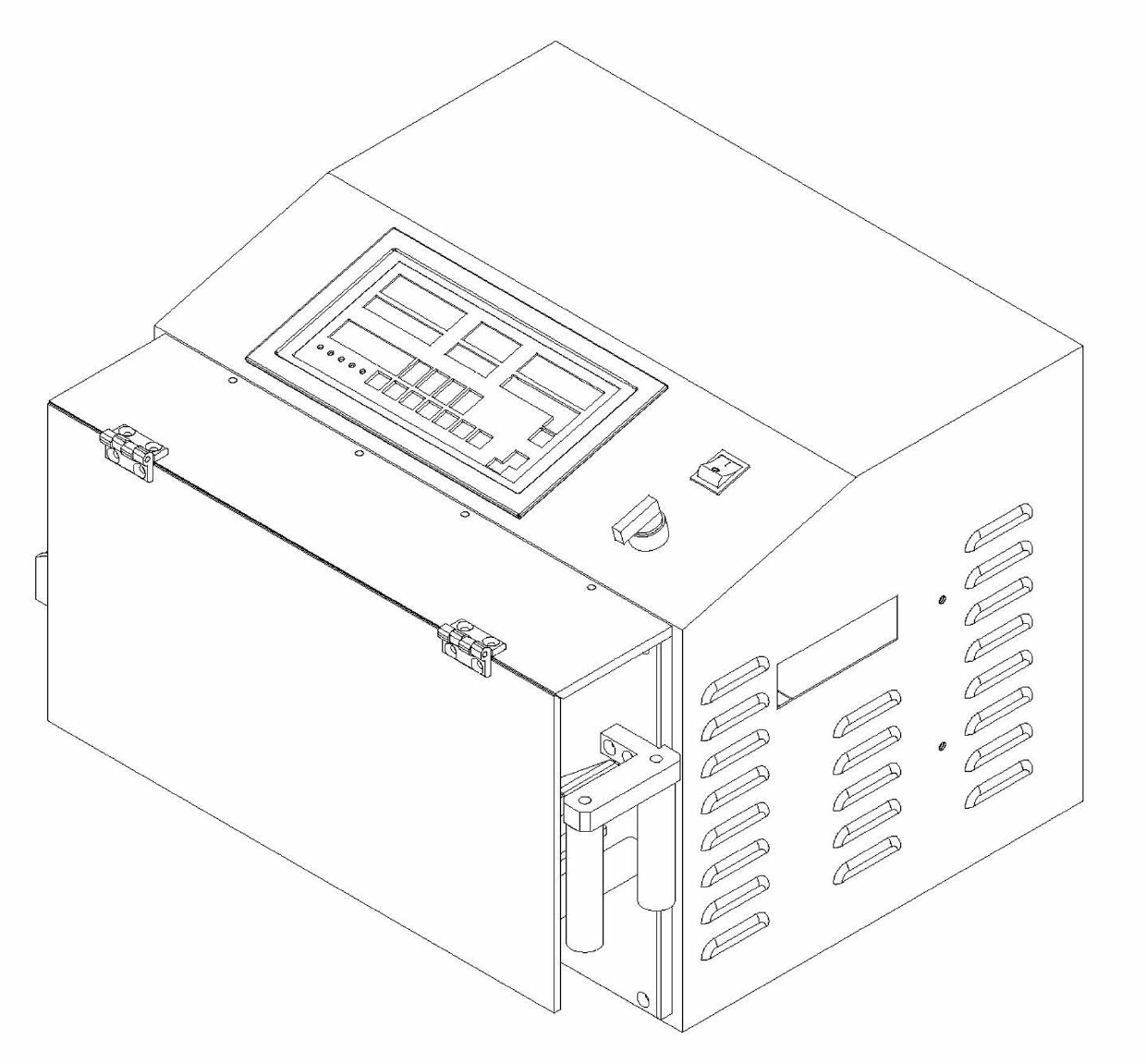

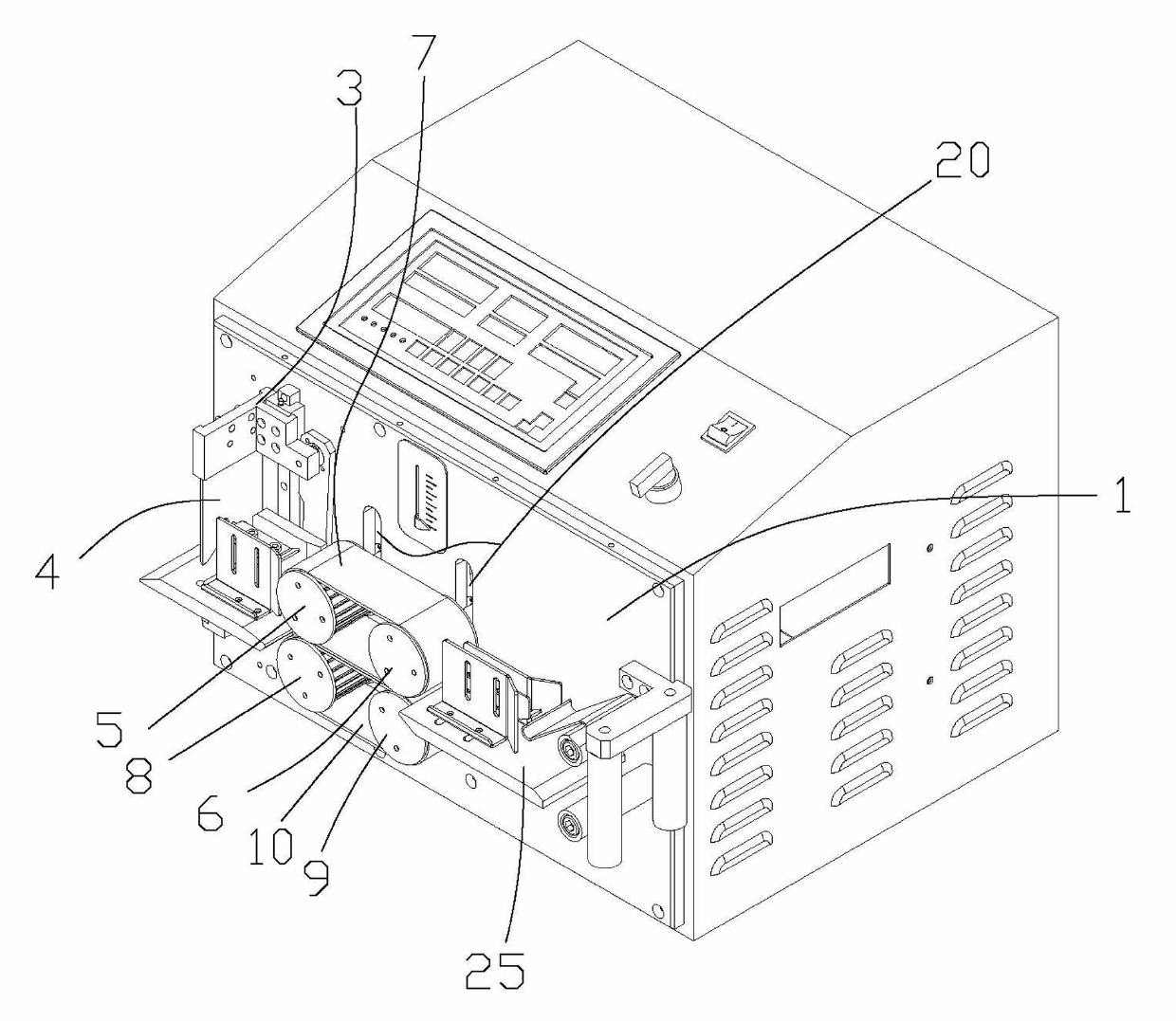

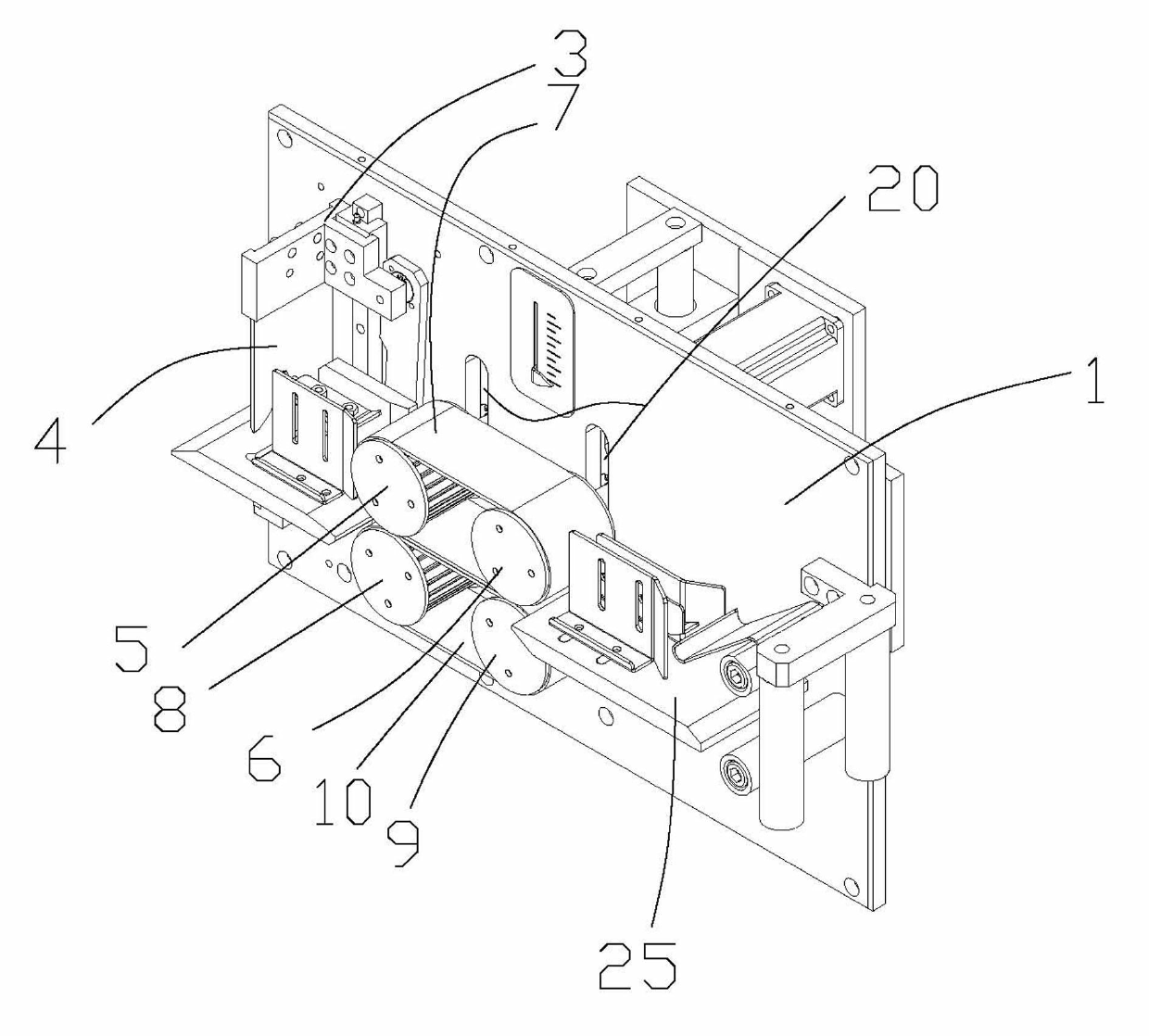

[0033] refer to Figure 1 to Figure 7 , the invention discloses a corrugated pipe cutting machine, comprising a frame 1, a cutter mechanism capable of cutting pipe materials, a feeding mechanism capable of feeding pipe materials into the cutter mechanism, a feed wheel gap adjustment mechanism and a control mechanism are arranged on the frame 1. mechanism, the feeding mechanism includes an upper pulley set, a lower pulley set, a first drive mechanism and a first transmission mechanism connected to the power output end of the first drive mechanism, the upper pulley set and the lower pulley set and The first transmission mechanism is connected, and the gap between the upper pulley set and the lower pulley set can be adjusted by the gap adjustment mechanism of the feeding wheel, and the control mechanism is electrically connected with the feeding mechanism, the cutter mechanism and the gap adjustment mechanism of the feeding wheel, Described cutter mechanism comprises the lower cu...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap