Tandem brake system

A technology of braking system and braking device, applied in the direction of mechanical braking transmission device, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

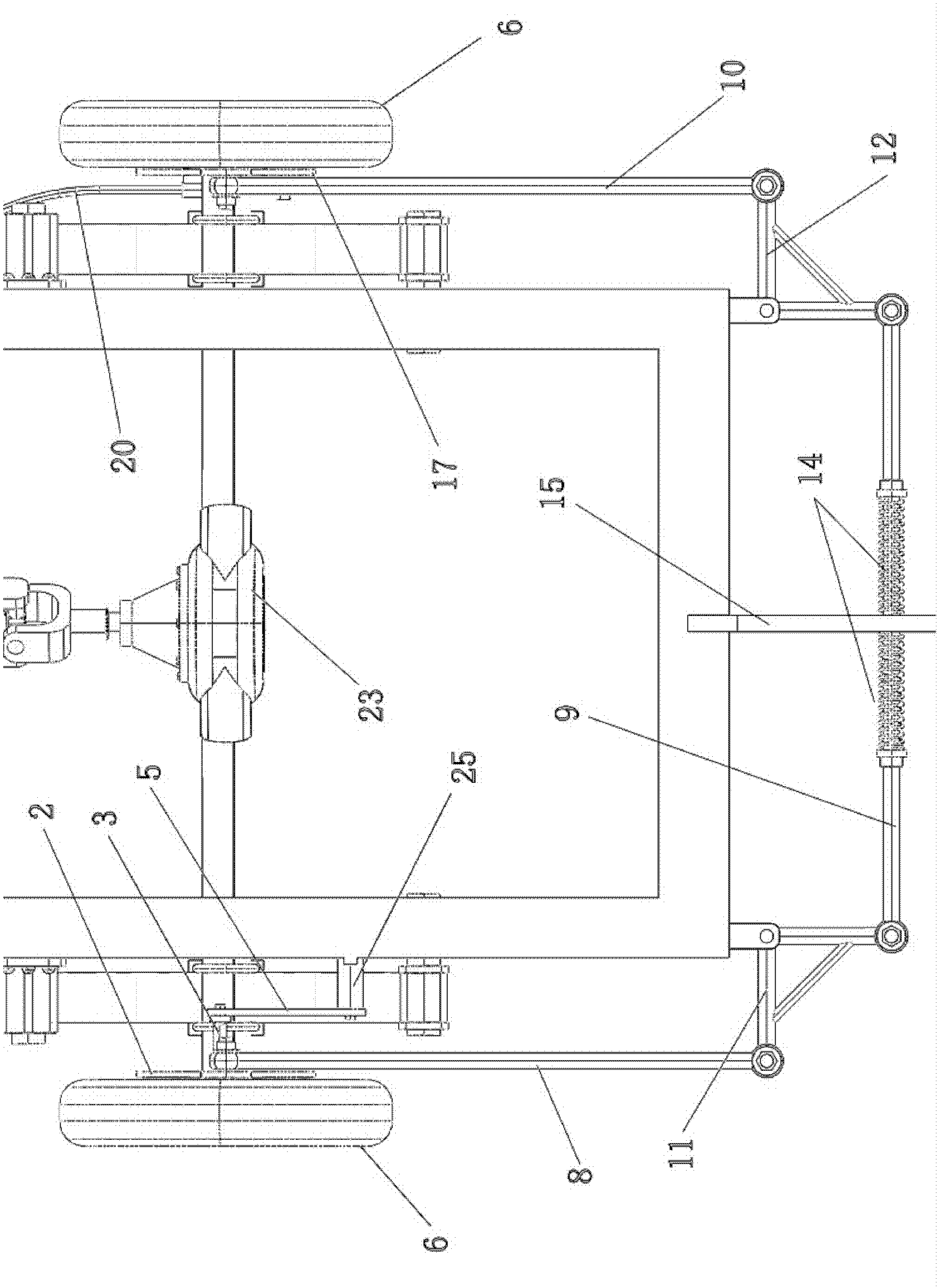

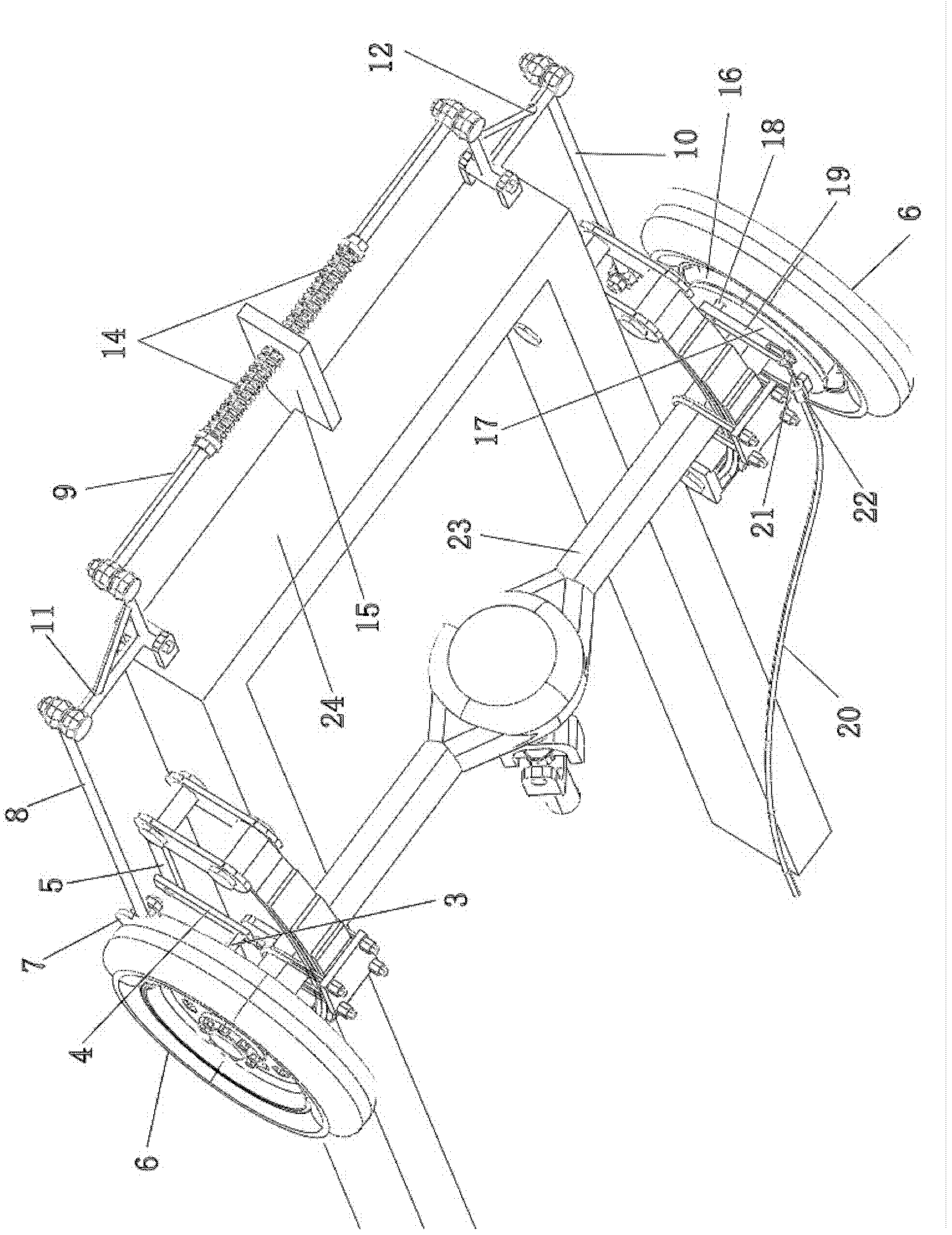

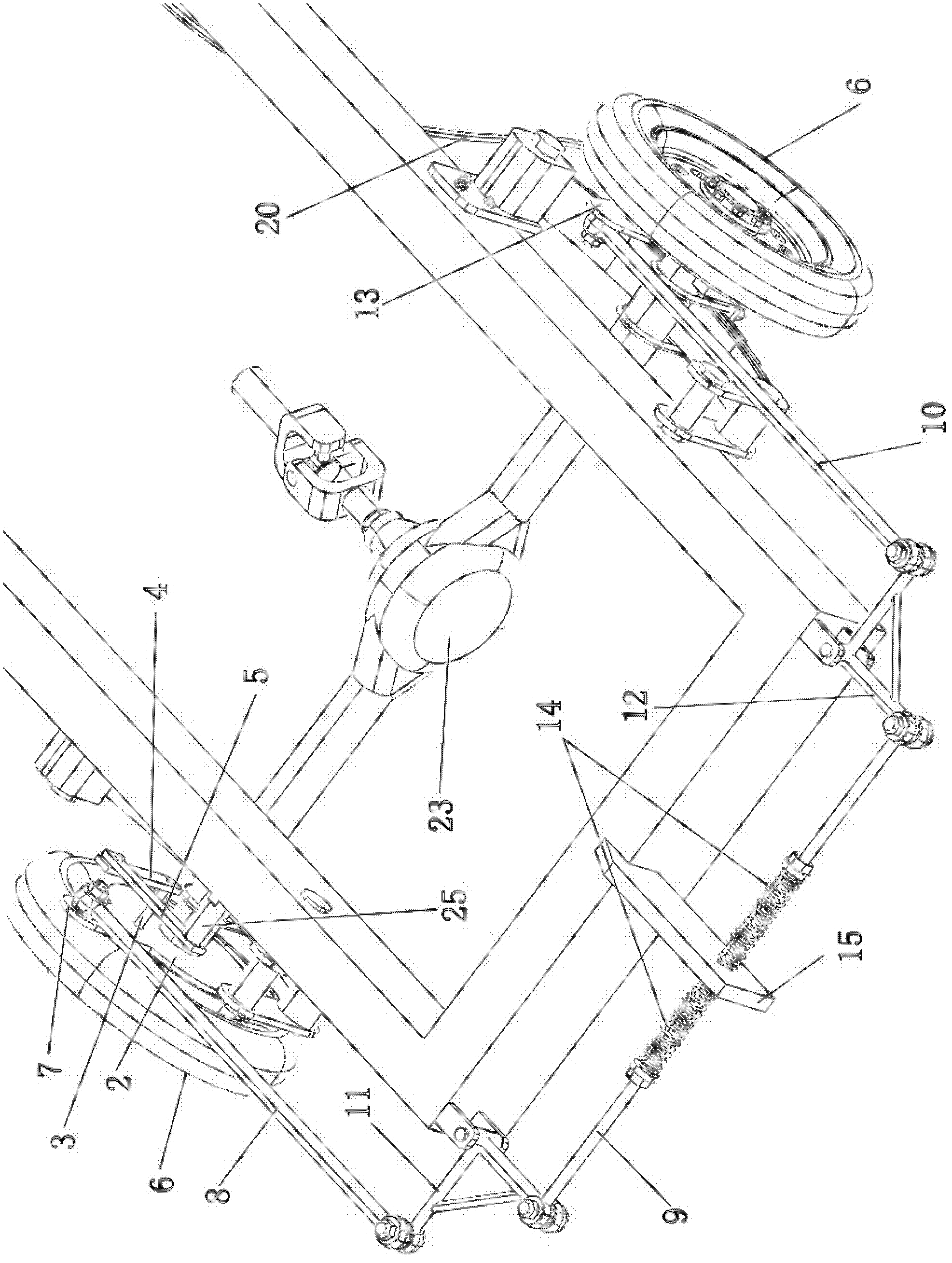

Embodiment Construction

[0010] Working principle: When the drum brake device is braking, the brake drum will drive the shoe plate to rotate through the brake shoe, and the shoe plate must provide sufficient reaction force to the brake shoe to achieve effective braking. The braking force of the drum brake depends on the pressure in the wheel cylinder or the angle of rotation of the camshaft and rocker arm. This program is to use these two protruding points to install the left and right shoe plates on the rear axle or the drive shaft so that it can rotate freely, and at the same time connect the two shoe plates through the transmission device so that they can be synchronously reversed. To rotate, one brake device drives the other brake device to rotate and brake. The transmission device mentioned here can be made of connecting rods, and can also be made of chains and the like. This example rear wheel 6, the right cam axle 18 on the right shoe plate 17 and the right rocking arm 19 accept the con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com