Moving box truck special for steel coil transportation

A technology of movable sheds and steel coils, which is applied to the transportation of passenger cars, transportation and packaging, trucks, etc., which can solve the problems of low efficiency, inconvenient operation and complicated operation of steel coil transportation, and achieve good structural waterproof performance and simple and convenient operation , Simple and reliable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

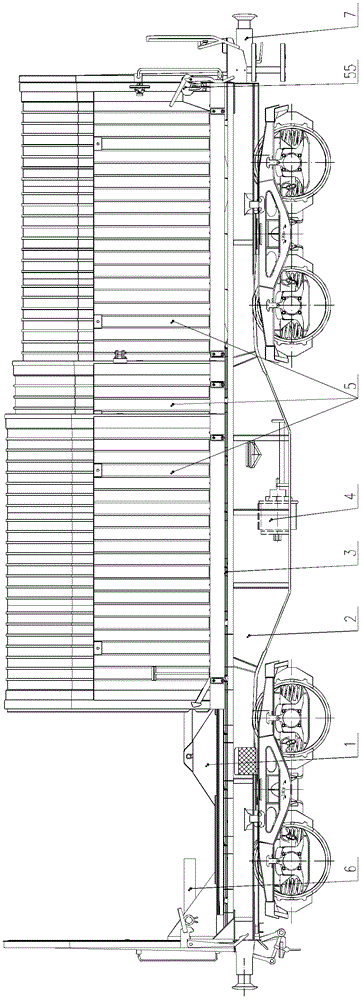

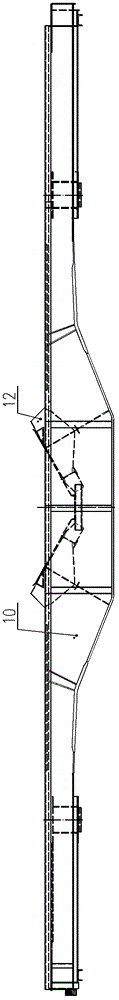

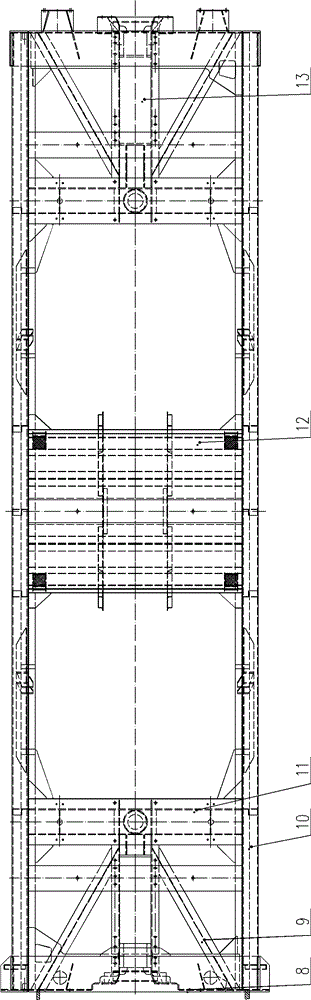

[0035] Such as figure 1 As shown, the special movable box car for steel coil transportation of the present invention is mainly composed of a body frame 1, an underframe 2, a guide rail 3, a wind hand brake device 4, a movable shed 5, a fixing device 6 and a coupler buffer device 7, etc. . The front and rear ends of the frame composition 2 are connected with the end wall composition 14 of the frame composition 1, the guide rail composition 3 is arranged on both sides of the frame composition 2, the frame composition 1 and the fixing device 6 are arranged on the frame composition 2; the movable shed Composition 5 has three sets, namely large movable shed composition 58, medium movable shed composition 57, and small movable shed composition 56, which are set together. They are respectively installed on the chassis composition 2 through the roller devices ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com