Guiding and locking device for testing degree of impact sensitivity of initiating explosive device

A locking device and impact sensitivity technology, applied in the field of measurement and testing, can solve problems such as low safety, secondary impact of pyrotechnics, and inability to quantify, to ensure accuracy and reliability, prevent secondary impact, and facilitate The effect of dismantling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] Structure and working principle of the present invention are set forth below in conjunction with accompanying drawing:

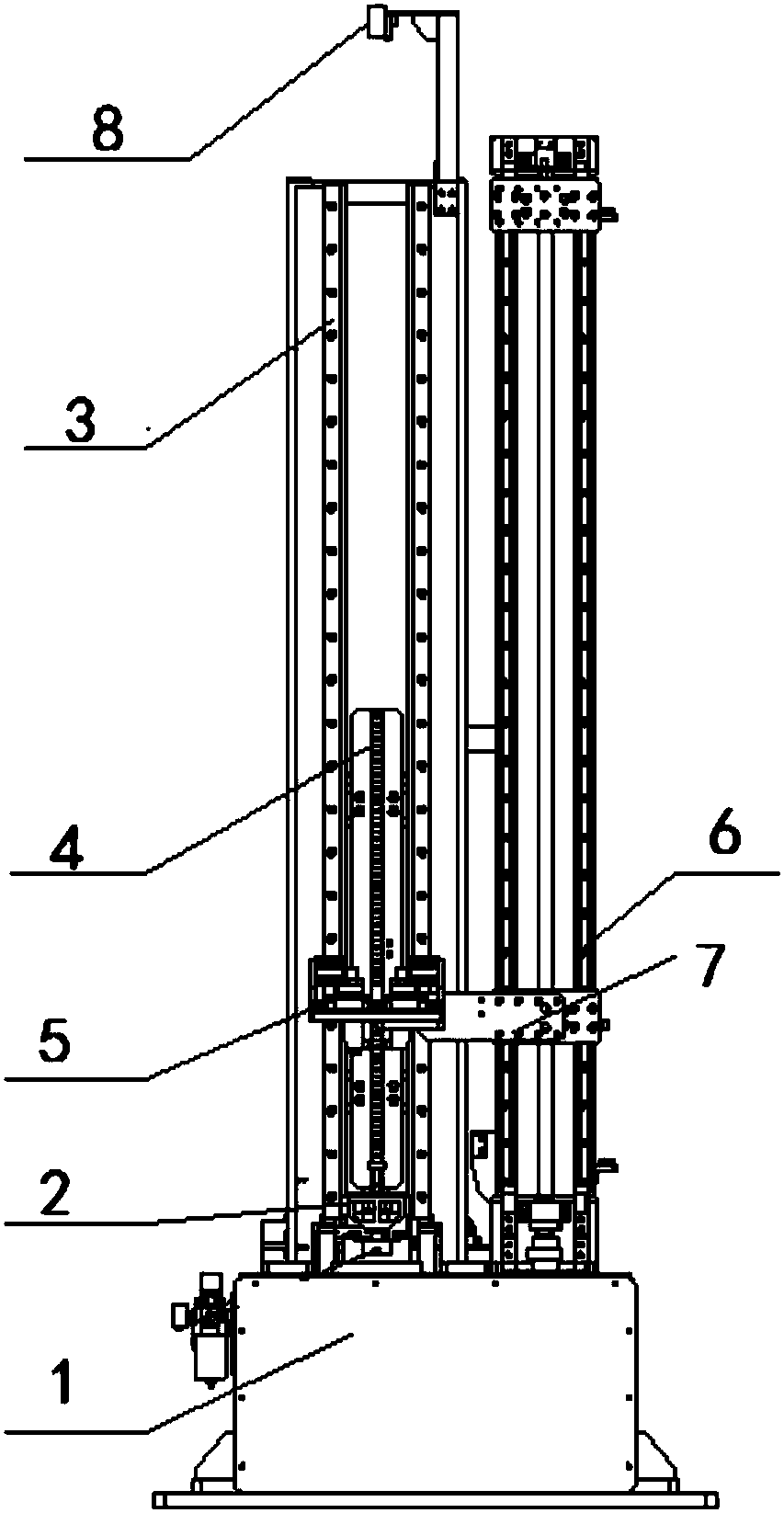

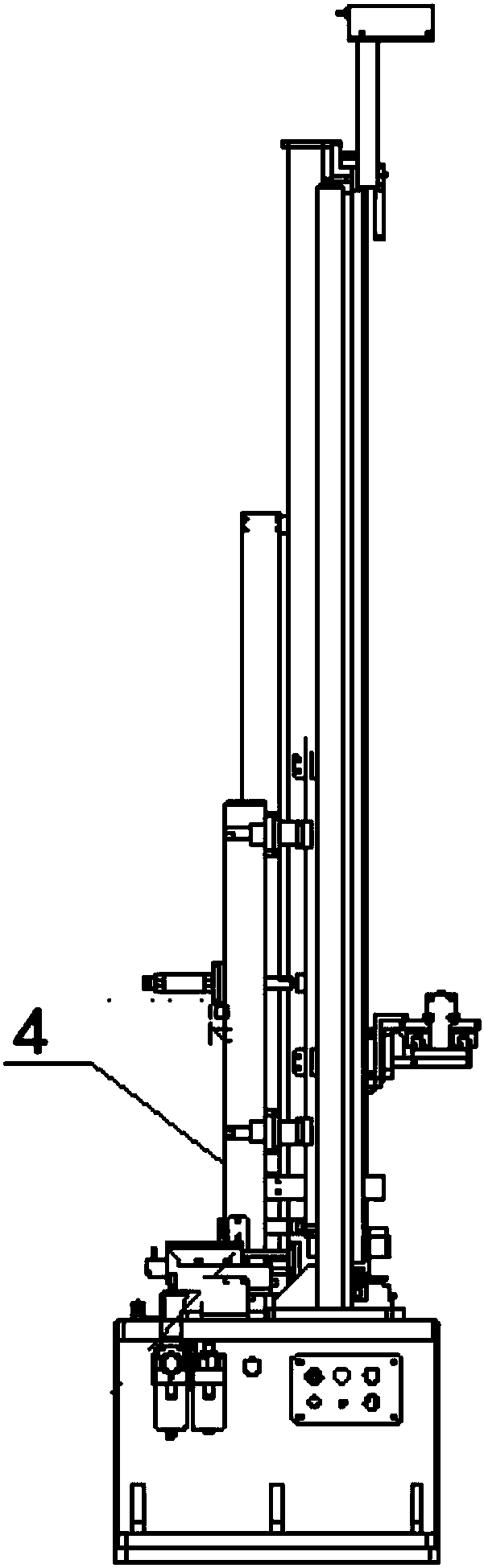

[0053] structure

[0054] Such as figure 1 and figure 2 As shown, a guiding and locking device for impact sensitivity testing of pyrotechnic products includes a base 1, a percussion hammer 2, a guiding device 3, a locking device 4, a clamping device 5 and a hoist 6;

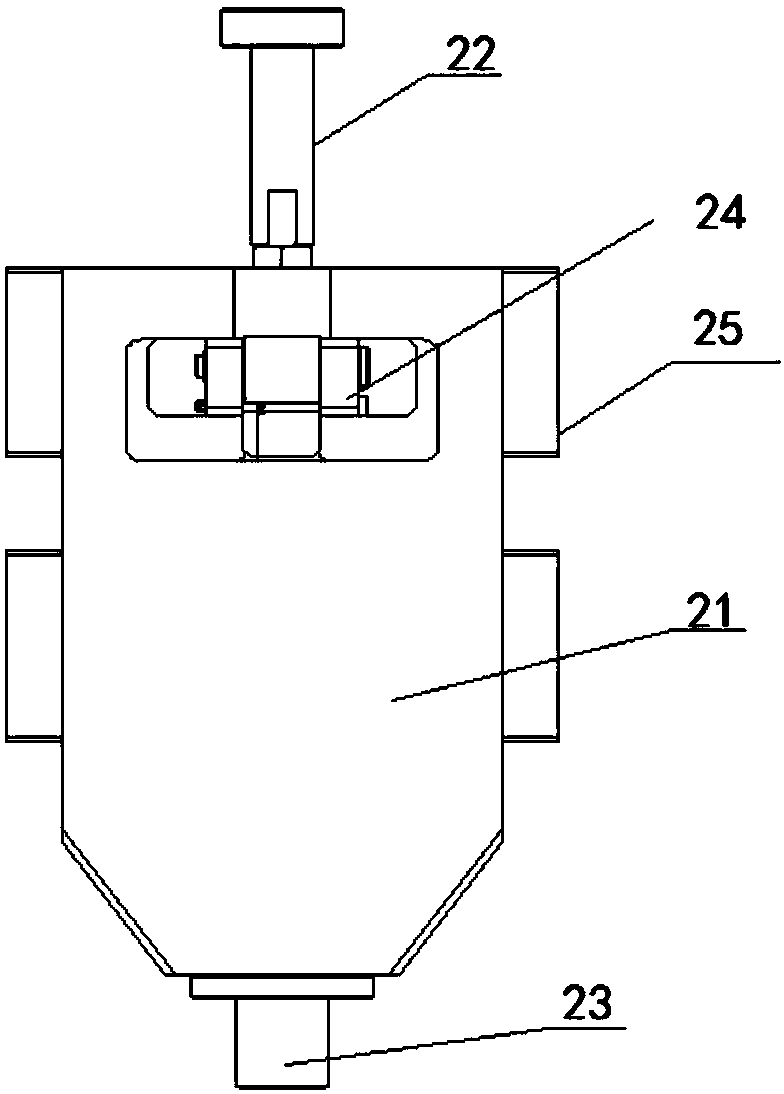

[0055] Both the guiding device 3 and the locking device 4 are installed on the base 1 and the locking device 4 is located behind the guiding device 3;

[0056] Such as image 3 and 4 As shown, the percussion hammer 2 includes a hammer body 21, a hammer head 22, a hammer handle 23 and a ratchet mechanism 24; Both sides are provided with guide grooves 25 (wherein the guide grooves are V-shaped); the hammer body 21 is provided with a ratchet mechanism 24 on the end face facing the locking device 4; The energy of falling from high places is large, which is easy to cause damage to the ha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com