Lightweight filled composite protective structure for space debris

A technology for composite protective structures and space debris, which is applied in the fields of aerospace safety/emergency devices, layered products, chemical instruments and methods, etc., can solve problems such as the difficulty in developing new protective materials with high performance, and the weak industrial foundation of materials, so as to reduce the Effects of speed, damage reduction, and duration of action

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention is described in further detail below in conjunction with accompanying drawing:

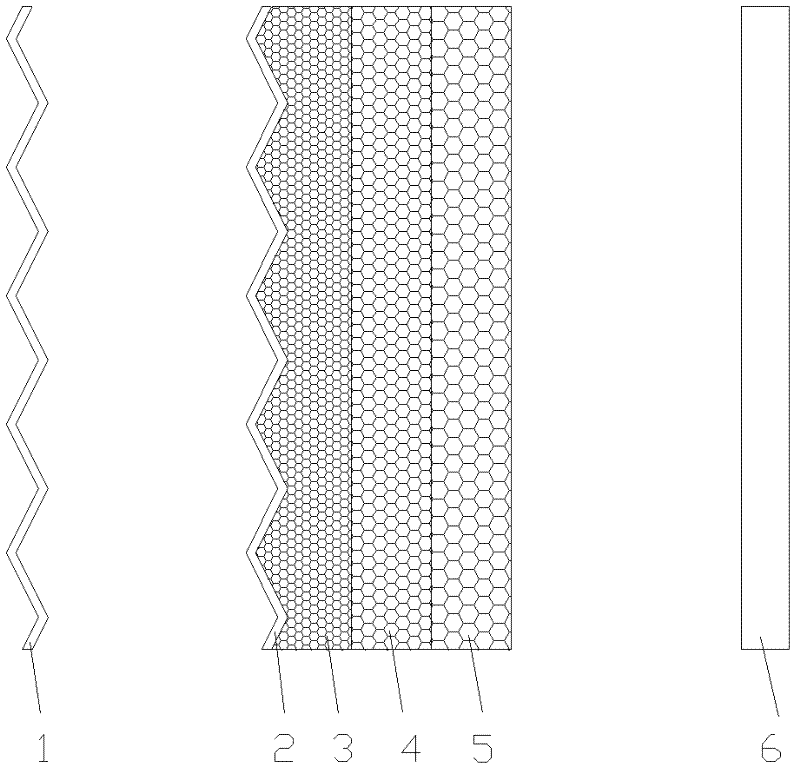

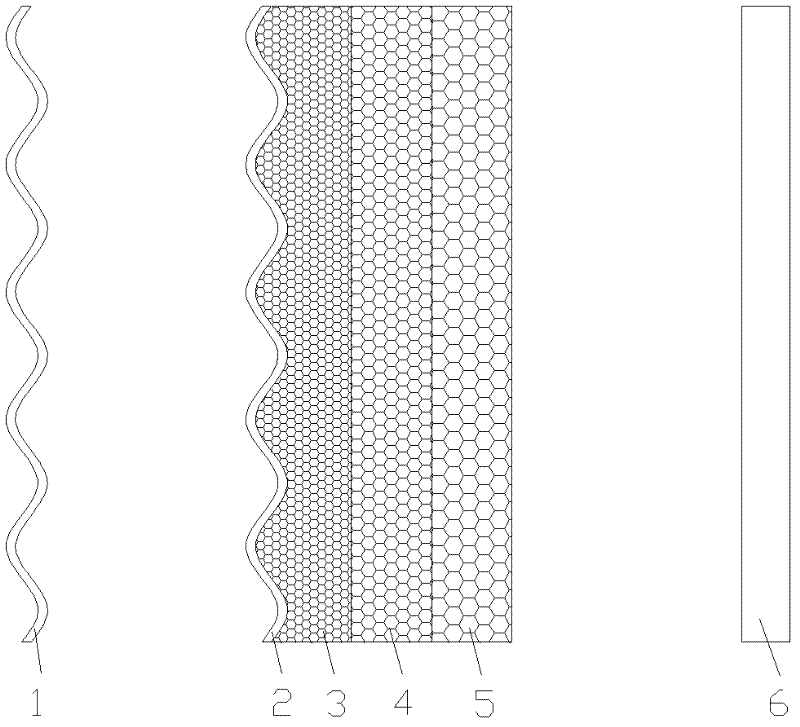

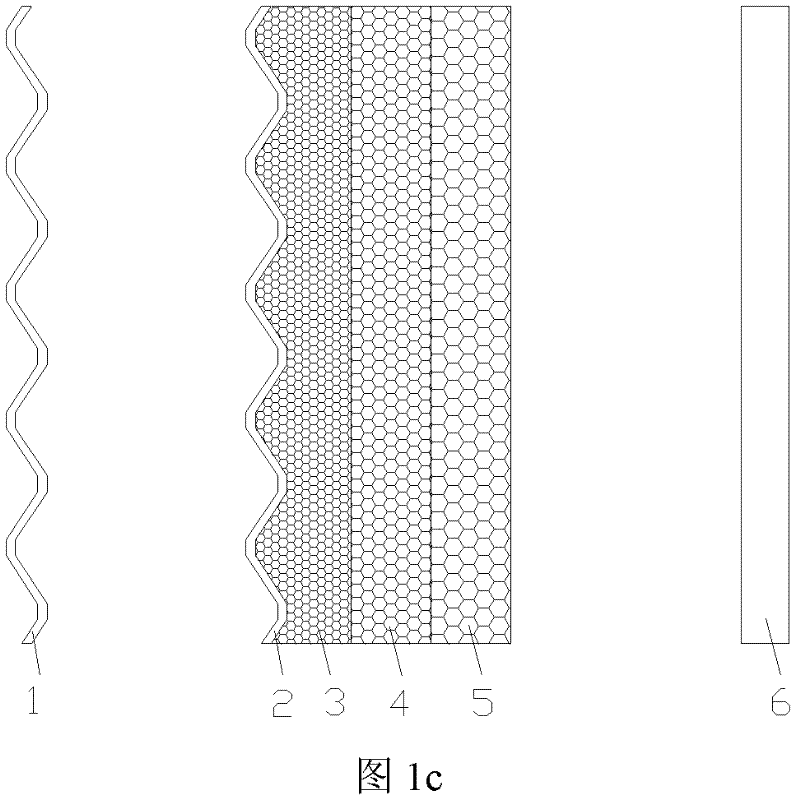

[0018] refer to Figure 1a , Figure 1b and figure 1 c, a light-weight filled space debris composite protection structure of the present invention, mainly comprising a first layer of protective screen 1, a second layer of protective screen corrugated board 2, high-density metal foam 3, lower-density metal foam 4 and low-density metal foam Density metal foam 5, bulkhead plate 6. The constituent materials of the corrugated plates 1 and 2 can be selected from metals such as: aluminum alloys, titanium alloys, etc.; non-metals can also be selected, such as: high-performance carbon fiber composite materials, high-performance ceramic fiber composite materials, and functionally graded composite materials; The thicknesses of 1 and 2 can be the same or different; the corrugated shape can be designed as triangular, sinusoidal and trapezoidal, etc.; metal foam layers 3, 4 and 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com