Signal acquisition device of correction controller

A signal acquisition and controller technology, applied in the directions of transportation and packaging, winding strips, thin material processing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

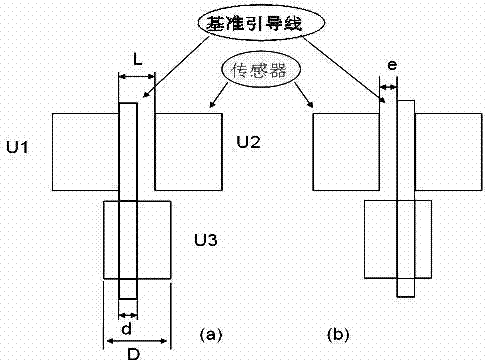

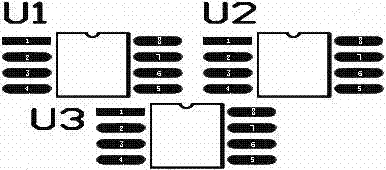

[0019] According to the description in the background technology, when the deficiencies of the deviation correction controller in the line detection mode, it is proposed to use the complementary interleaved layout of the two sensors. The PCB layout of the two sensors is as follows Figure 4 As shown, the detection areas of the two sensors overlap in a small range in the lateral direction, and the lateral overlapping distance e is in the range of 0-0.5 mm. At this time, as long as the reference guide line is greater than 0.5mm, any change of the reference guide line within the detection range of the sensor can cause effective changes in the sensor detection signal, so the detection blind zone of the deviation correction controller can be effectively eliminated. Such as Figure 4 As shown, 4(a) is the left deviation of the reference guide line of the detection object, and 4(b) is the right deviation of the reference guide line of the detection object. It can be seen that no matt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com