Temperature adjusting method for treating coal cake collapse and coal charging dead corner

A technology for temperature regulation and briquettes, which is applied in the heating of coke ovens, petroleum industry, and combustible gas heating coke ovens, etc. It can solve the problems of decreased production stability of coke ovens, difficulty in operation, and decreased coke quality, so as to prevent high-temperature accidents. and furnace door burning loss, ensuring coke quality, simple and practical operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

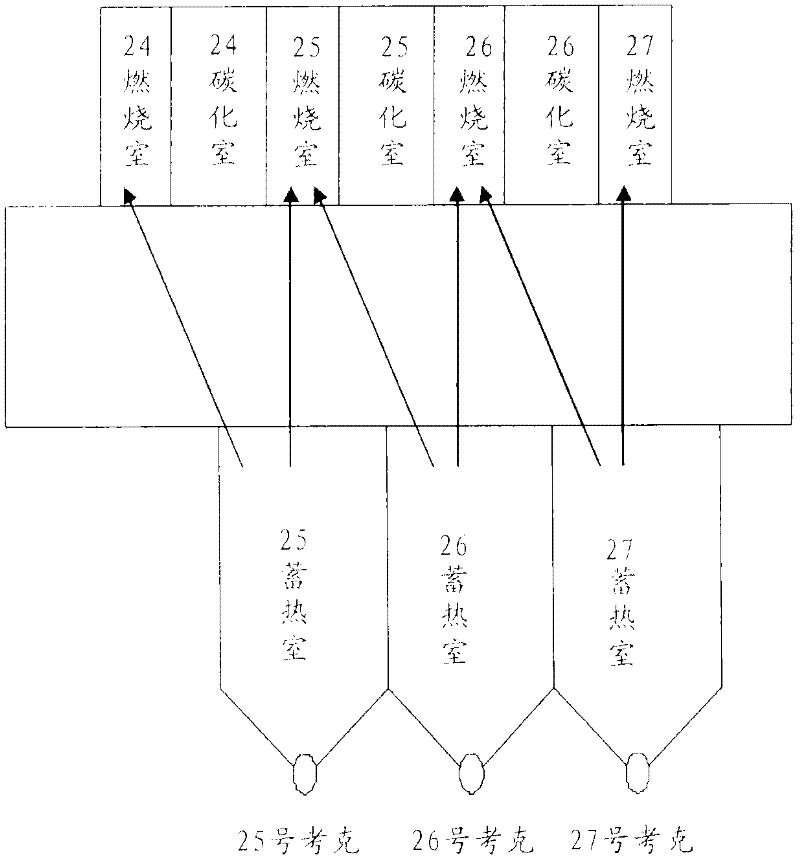

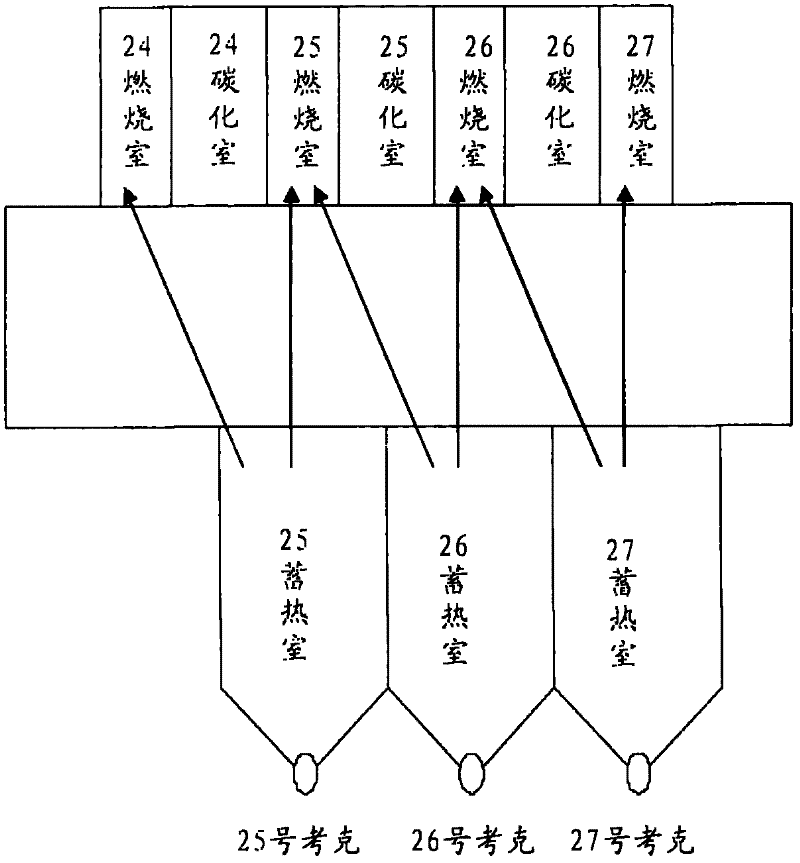

[0016] Hereinafter, exemplary embodiments of the present invention will be described in detail with reference to the accompanying drawings.

[0017] According to the prior art, the method of controlling the temperature in the furnace body that has been adopted is to control the temperature in the furnace body by adjusting the gas flow rate entering the furnace body. However, how and when gas flow is adjusted is critical.

[0018] Therefore, the inventors of the present invention conducted extensive studies and experiments. Through the research, it is found that in the early stage of coal charging, because the temperature of the coal cake is low and it is in a large amount of heat-absorbing stage, if the gas consumption is reduced prematurely, the corresponding carbonization room temperature will be too low, which will lead to insufficient coke maturity and affect the coke quality; Reducing the gas consumption too late will lead to high temperature and excessive coke. Accordi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com