Swing type limited slip differential

A limited-slip differential and swing-type technology, which is applied in the direction of differential transmission, transmission, belt/chain/gear, etc., can solve the problems of deviation from the best position, driving torque cannot be effectively transmitted and timely response, etc., to achieve The effect of ensuring meshing accuracy and driving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Below in conjunction with accompanying drawing, content of the present invention is described in detail:

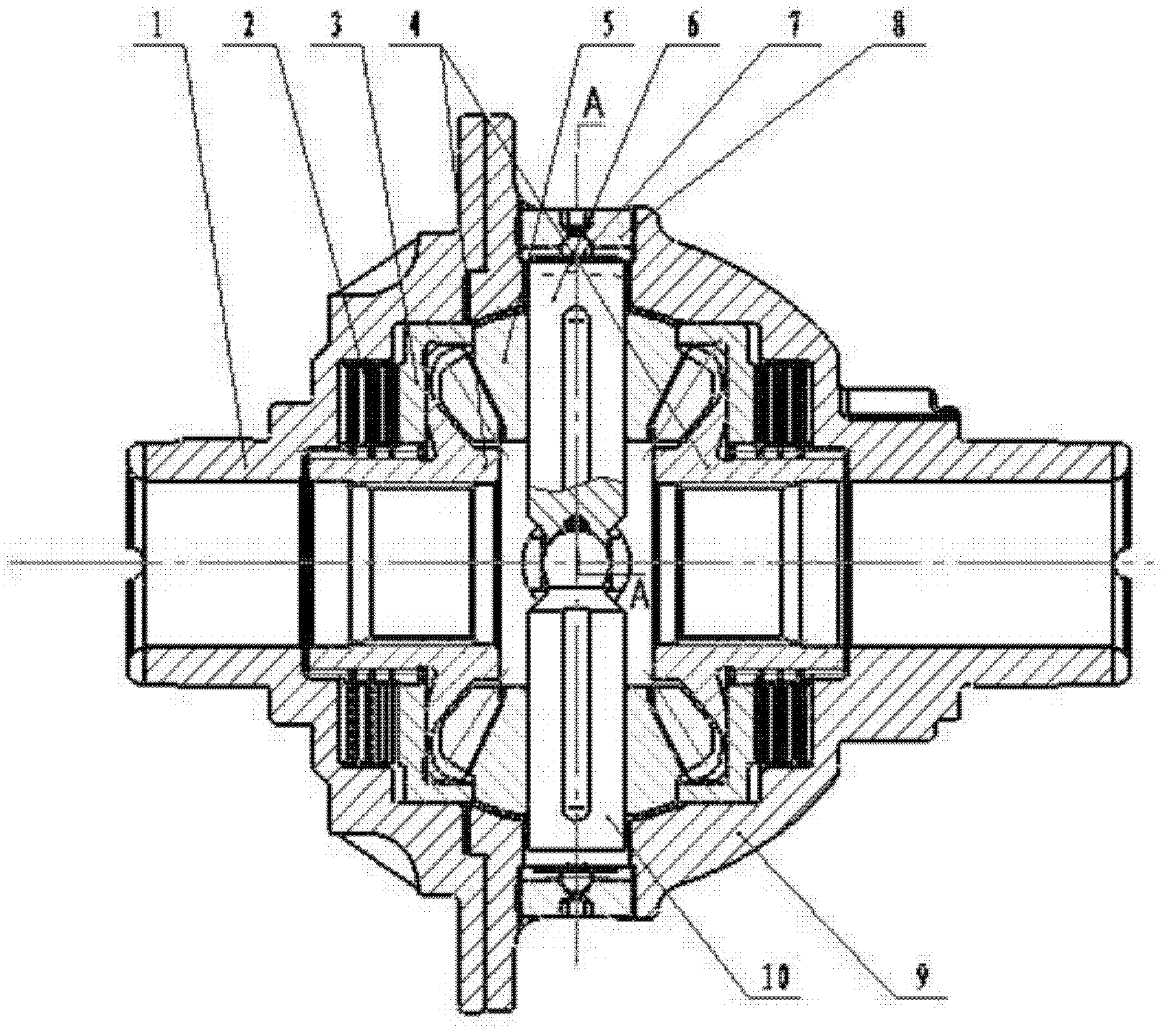

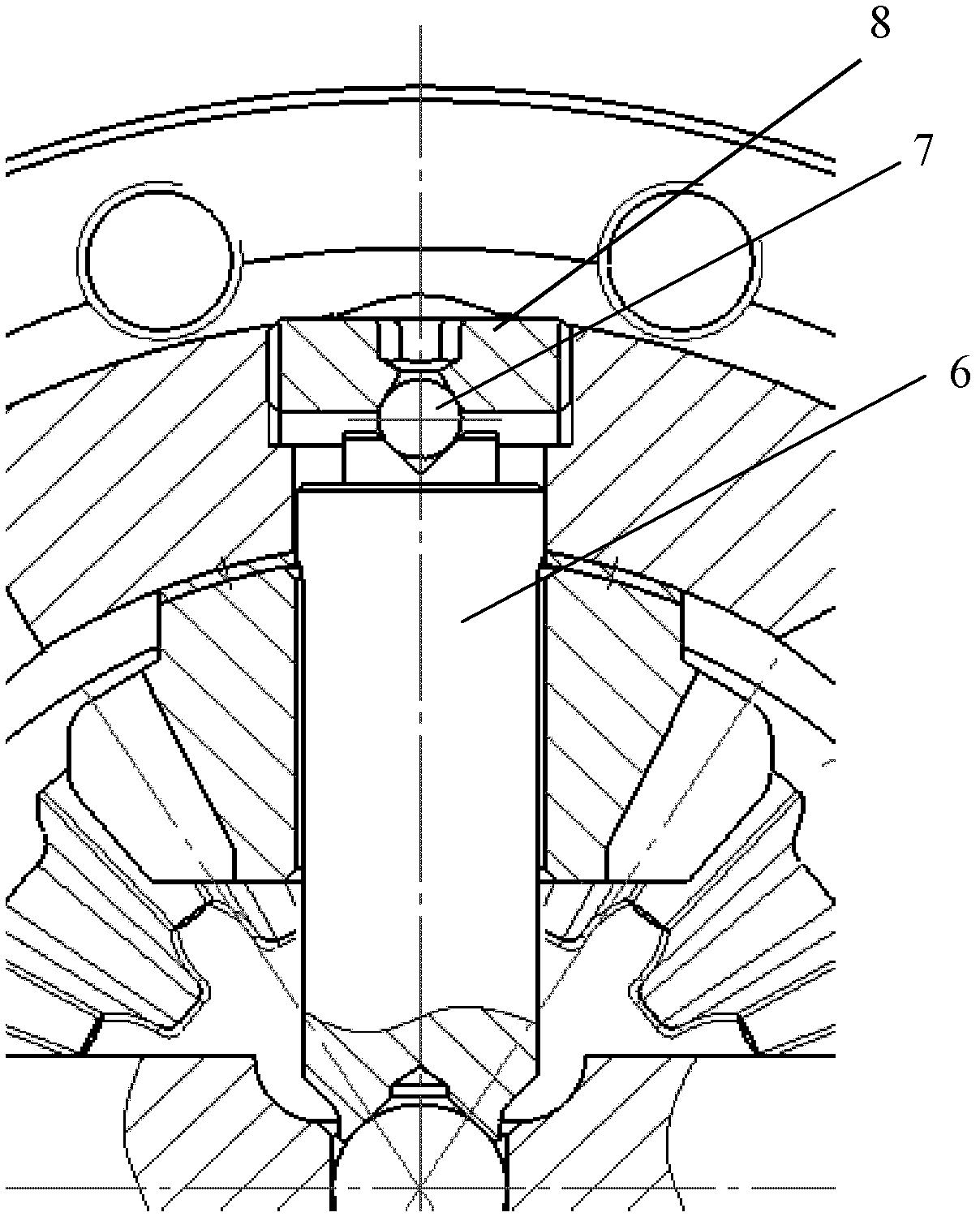

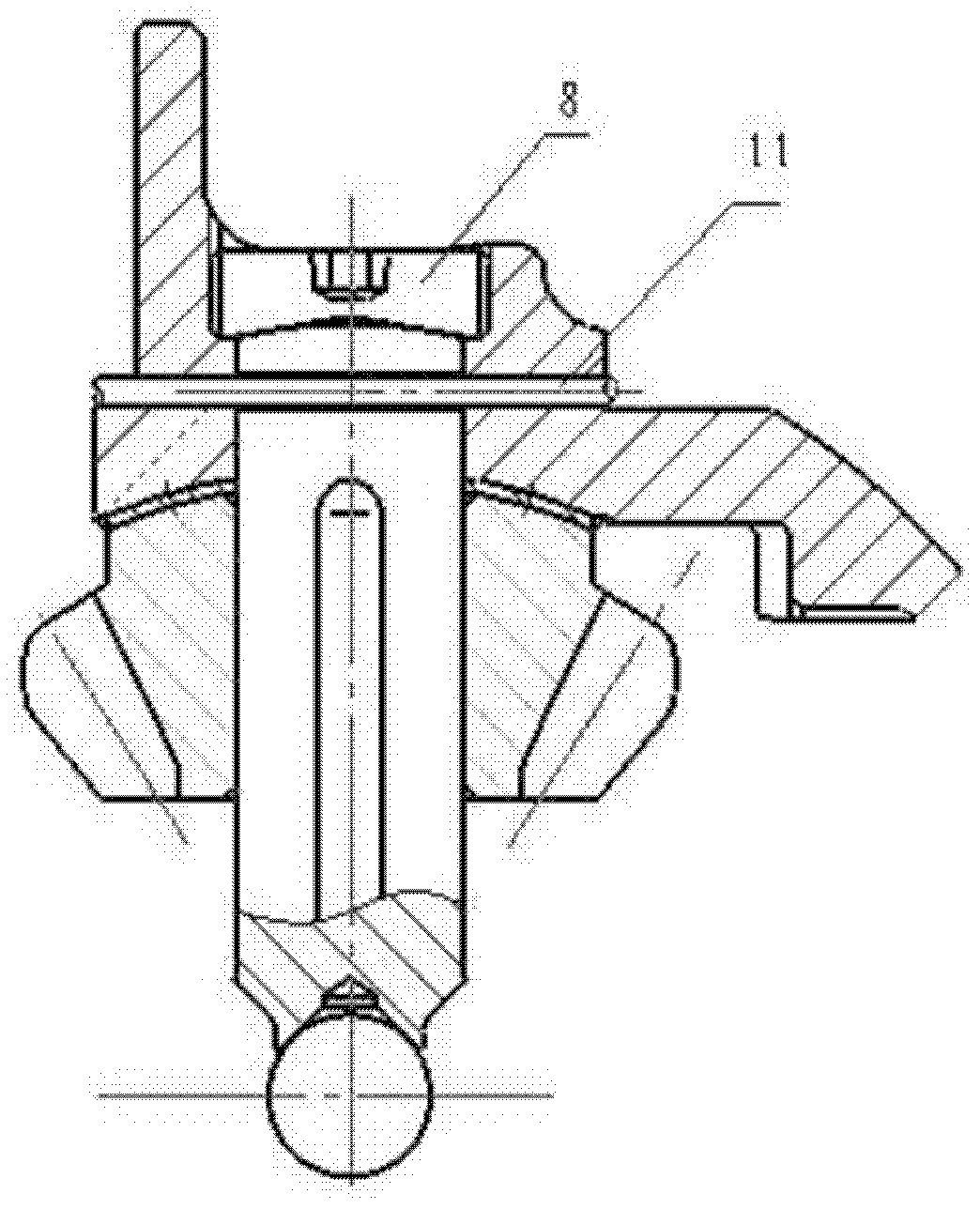

[0018] The oscillating anti-slip differential proposed by the invention can realize the swing of the planetary gear with the common cone top of the planetary gear and the side gear as the center of the circle. Ensure proper meshing of bevel gear pairs. The main structure is similar to the general limited-slip differential, consisting of housing 9, side gear 4, planetary gear 5, planetary gear shaft 6, friction plate 2, pressure plate 3, and some auxiliary connectors. Its working principle is that when one side of the wheel slips and loses or reduces the driving torque, the internal mechanism automatically adjusts the larger driving torque of the other side of the wheel instantaneously, (theoretically without any hysteresis) to reach the driving torque on both sides Redistribution ensures safe driving when the vehicle skids and turns.

[0019] The design features ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com