Stop valve

A shut-off valve and valve body technology, which is applied in the field of water-cooled ultra-high temperature shut-off valves, can solve the problems of easy deformation of the valve core and weakened sealing effect, and achieve the effects of enhancing cooling, preventing dead water areas, and enhancing cooling and heat transfer effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

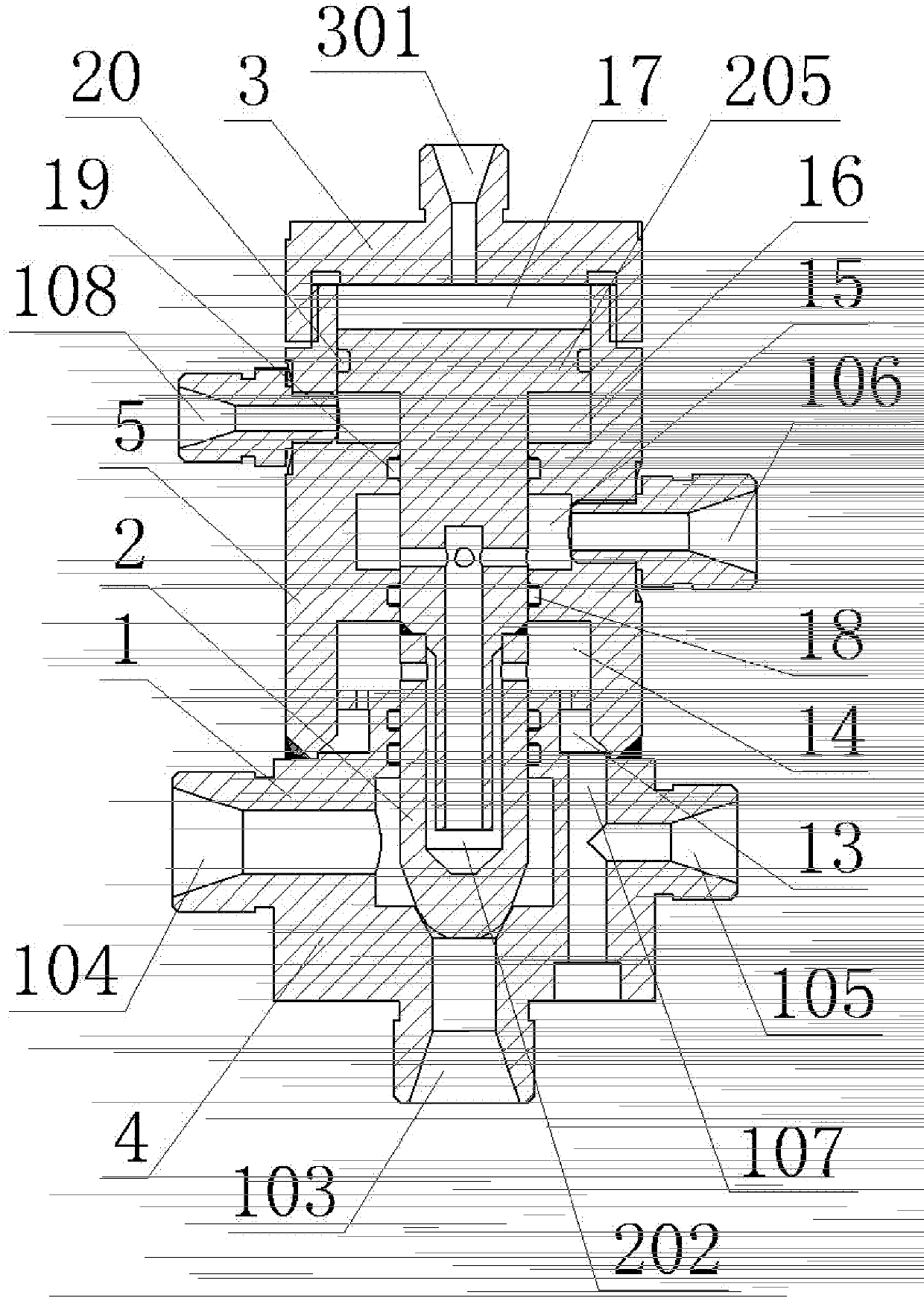

[0026] see figure 1 , the cut-off valve of the present invention is mainly used in high-temperature fluid pipelines to realize the on-off of high-temperature fluids. It is arranged in the valve body 1, and the valve core 2 can move back and forth along the axial direction in the valve body 1. A sealing mechanism is provided between the valve core 2 and the valve body 1 , and when the high-temperature fluid flows through the valve body 1 , the high-temperature fluid can be cut off through the engagement of the valve core 2 and the valve body 1 .

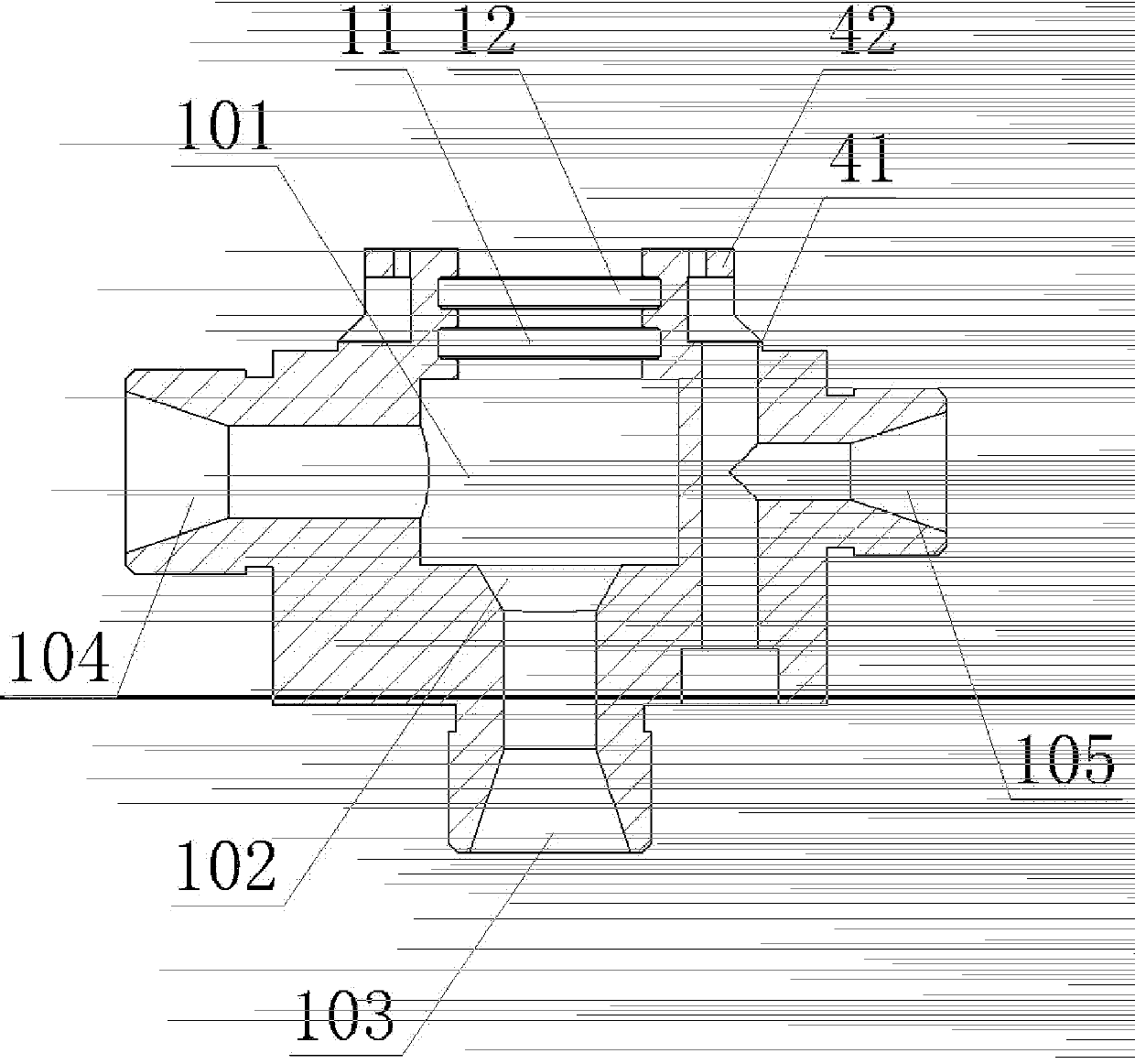

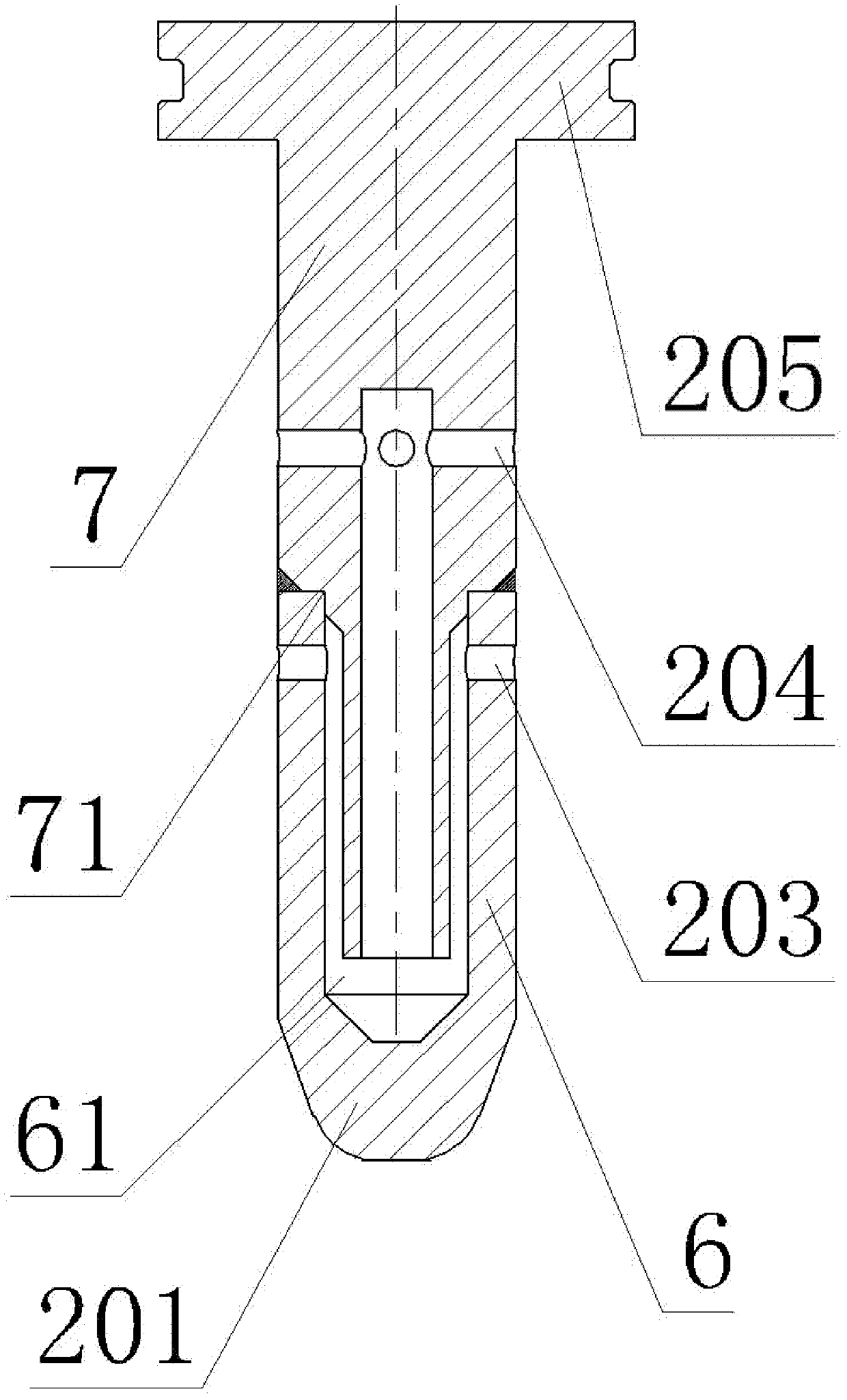

[0027] see in conjunction figure 2 and image 3 , the valve body 1 is provided with a valve chamber 101 and a sealing cone 102, the valve body 1 is provided with a fluid inlet nozzle 103 and a fluid out...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap