LED (Light-Emitting Diode) three-dimensional packaging-based vehicle headlamp and vehicle illumination method

A technology for automotive headlights and three-dimensional packaging. It is applied in lighting devices, fixed lighting devices, and lighting auxiliary devices. It can solve the problems of inability to provide the total luminous flux of headlights, low integration of planar light sources, and large volume, and achieve high efficiency. Reliable heat transfer performance, simple structure, small size effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

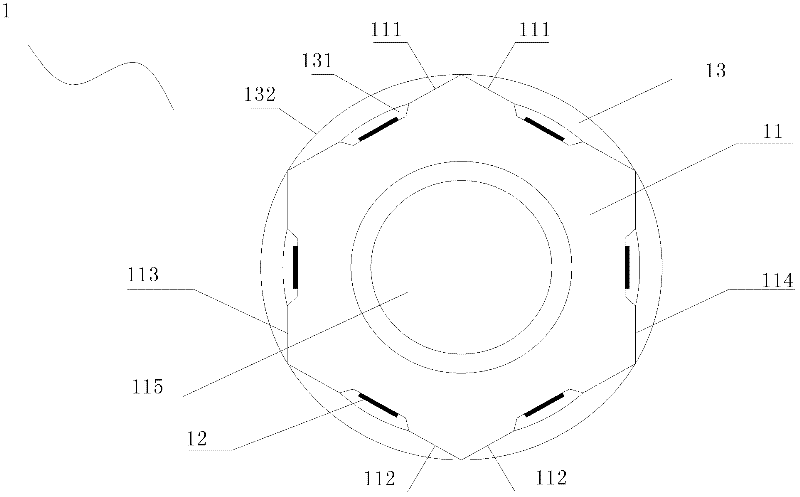

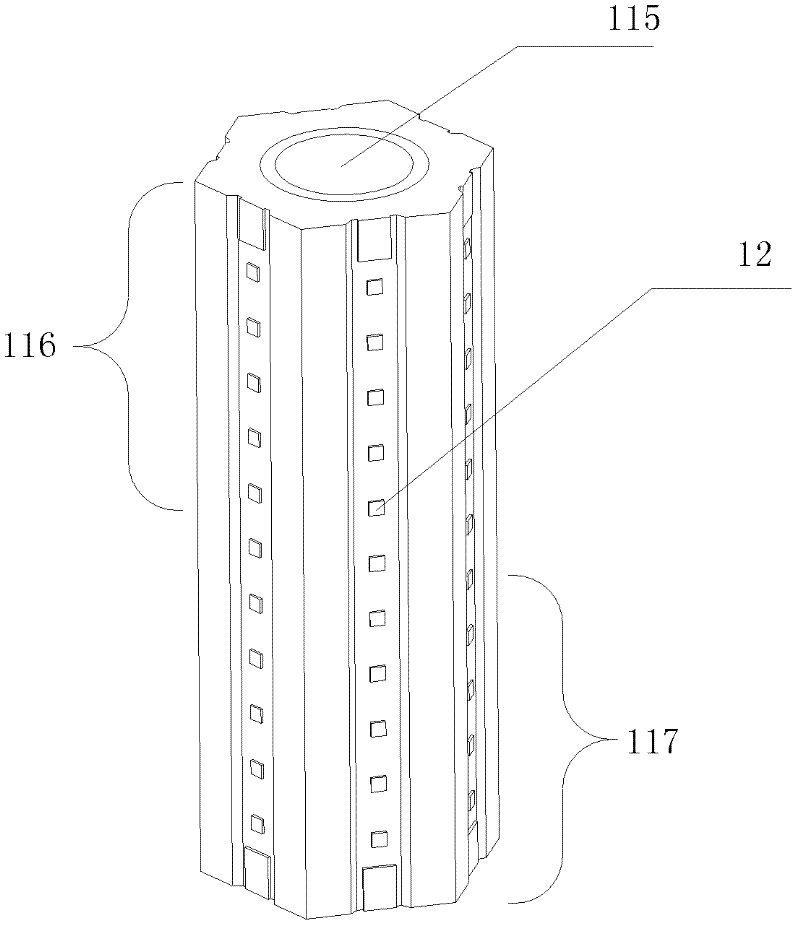

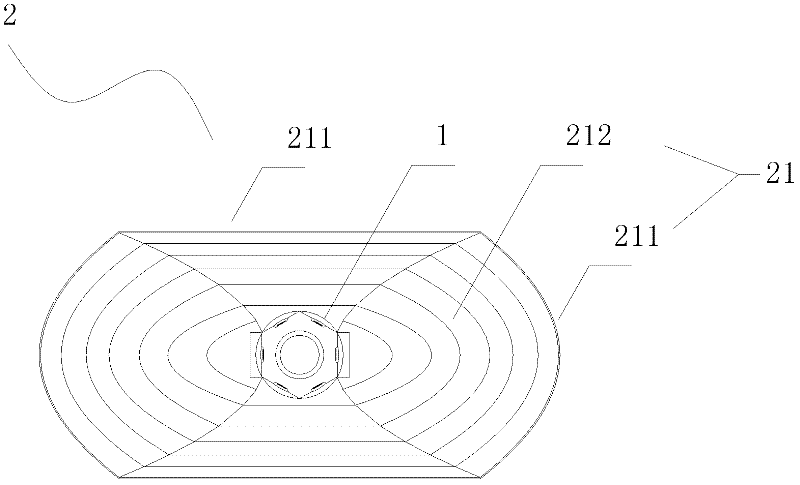

[0059] like Figure 1A , 1B As shown, the LED three-dimensional package light source 1 in this embodiment includes a base 11, an LED chip 12 arranged on the base 11, and a package body 13 covering the LED chip 12. The inner encapsulation layer 131 and the outer surface 132 of the encapsulation body 13 are non-planar curved encapsulations to provide different light distribution curves.

[0060] In this embodiment, the base 11 is a hexagonal prism, and each side of it is used as a chip mounting surface. The base 11 has two upper mounting surfaces 111, two lower mounting surfaces 112, a left mounting surface 113, and a right mounting surface. On the mounting surface 114 , each LED chip mounting surface faces different directions, and each LED chip mounting surface is mounted with a plurality of LED chips 12 . The center of the base 11 is provided with a mounting hole 115, and the cross section of the mounting hole 115 is circular or other polygonal structures. The LED three-dim...

Embodiment 2

[0064] like Figure 4 As shown, the difference between this embodiment and Embodiment 1 is that the inner wall of the reflector 41 is only composed of a plurality of large reflective surfaces 411, and a plurality of large reflective surfaces 411 are arranged to form a free-form surface with a narrow bottom and a wide top, and each reflective surface 411 Corresponding to each independently light-controllable light-emitting area, the light-emitting area is composed of one or more chip mounting surfaces.

Embodiment 3

[0066] like Figure 5 As shown, the difference between this embodiment and Embodiment 1 is that the reflective surface of the reflector 51 is only composed of a smooth curved surface 511, which is a free curved surface with a narrow bottom and a wide top. The smooth curved surface 511 is divided into multiple regions along the light emitting direction, and the The curvature is different.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com