Measuring rod device for inner-ring raceway of pivoting support

A technology of slewing bearings and measuring rods, which is applied in the direction of mechanical diameter measurement, etc., can solve the problems of low efficiency, cumbersome measurement process, large measurement error of vernier calipers, etc., and achieve the effect of eliminating measurement error, convenient connection, and lower assembly failure rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

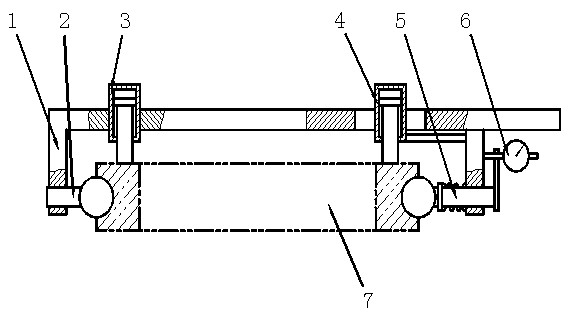

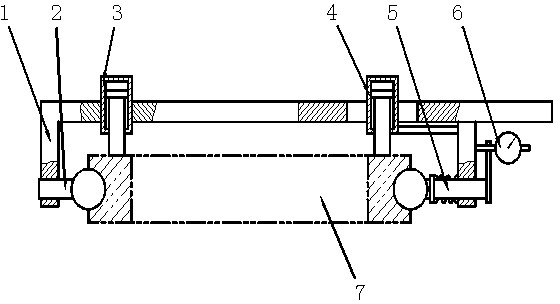

[0014] Before the measurement, first select the corresponding calibration device according to the accuracy requirements of the raceway to be tested. Move the scale of the calibration device to the measured nominal size and lock it. The operator adjusts the position of the moving probe 5 to the position close to the opening of the calibration device according to visual inspection. At this time, the spring mechanism of the moving probe 5 should be completely relaxed without external pressure. Then fine-tune and move the measuring head 5 a certain distance inwards and lock it. This distance is related to the spring coefficient and the model of the measuring rod device.

[0015] After adjusting the moving probe 5, put the steel balls at the ends of the two measuring heads of the measuring rod against the calibration device, and set the pointer of the dial indicator at this position to zero, that is, when the moving probe 5 moves to the zero of the dial indicator, absolute Dimensi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com