Automatic sample dissolving device

A sample-dissolving and automatic technology, which is applied in the field of metal element analysis and automatic sample-dissolving device, can solve the problems of long-time-consuming dissolution of standard samples, production accidents, and operator injury, etc., and achieves fast sample dissolution, simple operation, The effect of reducing pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

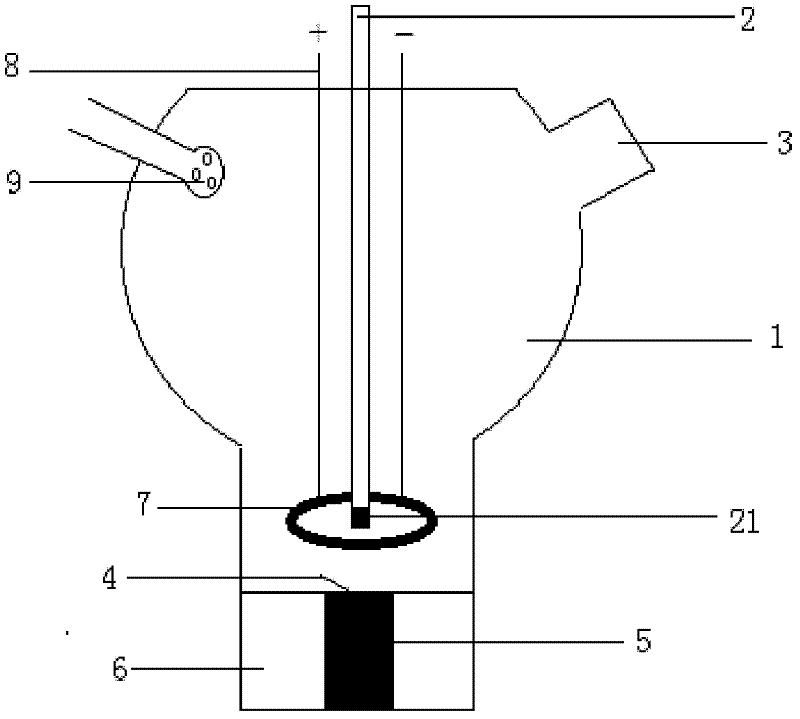

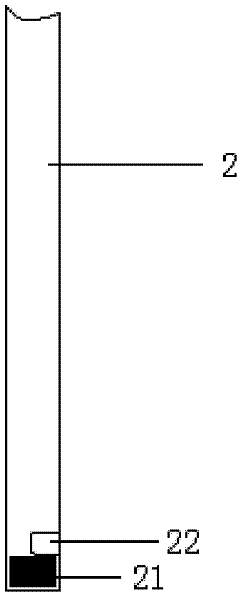

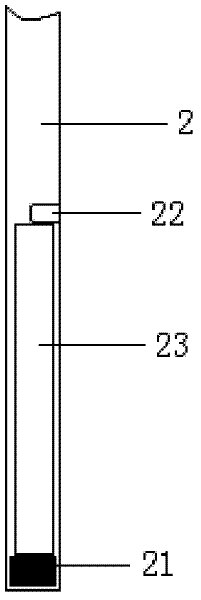

[0018] Such as figure 1 The automatic sample dissolving device of the present invention comprises a mother liquor container 1, an adsorption rod 2, a tantalum wire 7, a drain valve 5, a drain coil 6 and an electrode 8, and the mother liquor container 1 is provided with a sample inlet 3 and a sample dissolution outlet 4, and a sample dissolution outlet 4 is located at the bottom of the mother liquor container 1, the adsorption rod 2 extends into the lower part of the mother liquor container 1, and one end of the extension is suspended in the air, the adsorption rod 2 is a hollow glass tube, and the suspended end is closed and has a built-in magnet 21; the drain valve 5 is located at the bottom of the mother liquor container 1 Dissolving sample outlet 4, liquid discharge coil 6 is an electromagnetic switch coil, which controls the opening and closing of liquid discharge valve 5; tantalum wire 7 surrounds the suspended end of adsorption rod 2, and tantalum wire 7 is connected to e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com