Mortar surface layer and base body tensile bonding intensity detecting clamp and detecting method

A technique for tensile bonding strength and testing fixtures, applied in the direction of strength characteristics, using stable tension/pressure testing material strength, measuring devices, etc. The cleaning of the adhesive on the surface of the board is time-consuming and labor-intensive, and the bonding surface is wet, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

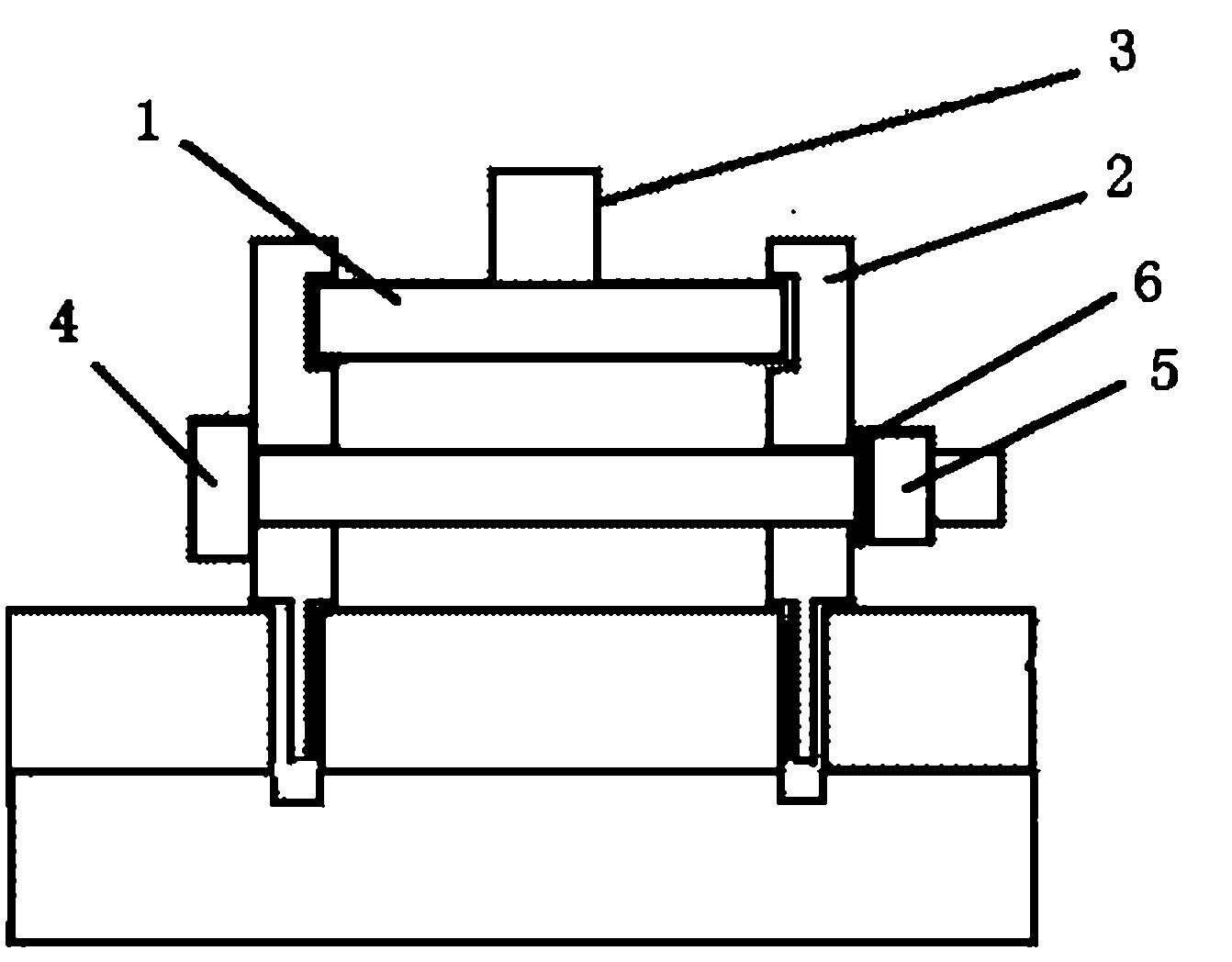

[0044] Such as figure 1 As shown in the present invention, a test fixture for the tensile bond strength between the mortar surface and the substrate includes a top drawing plate 1, fasteners and two splints 2; the center position of the top drawing plate 1 is provided with a The joint 3 connected by the bond strength tester; the fastener includes a bolt 4, a nut 5 and a washer 6; wherein, the top drawing plate is a circular plate with a diameter of 50mm.

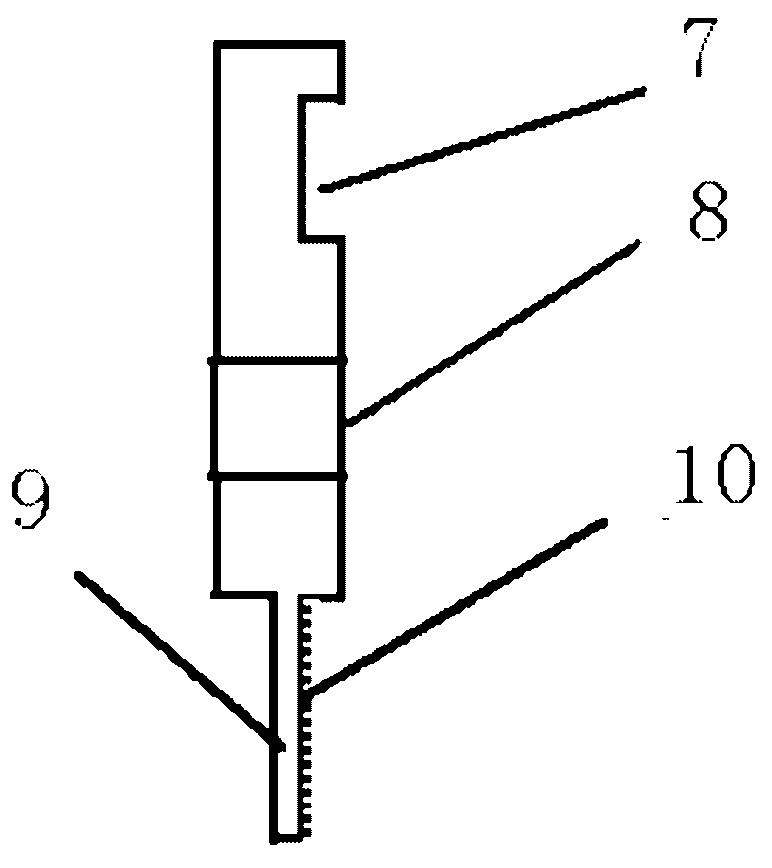

[0045] Such as figure 2 As shown, the upper and middle parts of each plywood are semi-cylindrical, the upper part is provided with a groove 7; the middle part is provided with a bolt hole 8, and the lower part is a clamping part 9 for clamping the mortar surface; the clamping part 9 is semi-cylindrical , the side in contact with the mortar surface layer is provided with a score 10 . In this embodiment, the cross-sectional area of the middle part of the splint is larger than the cross-sectional area of the clamping par...

Embodiment 2

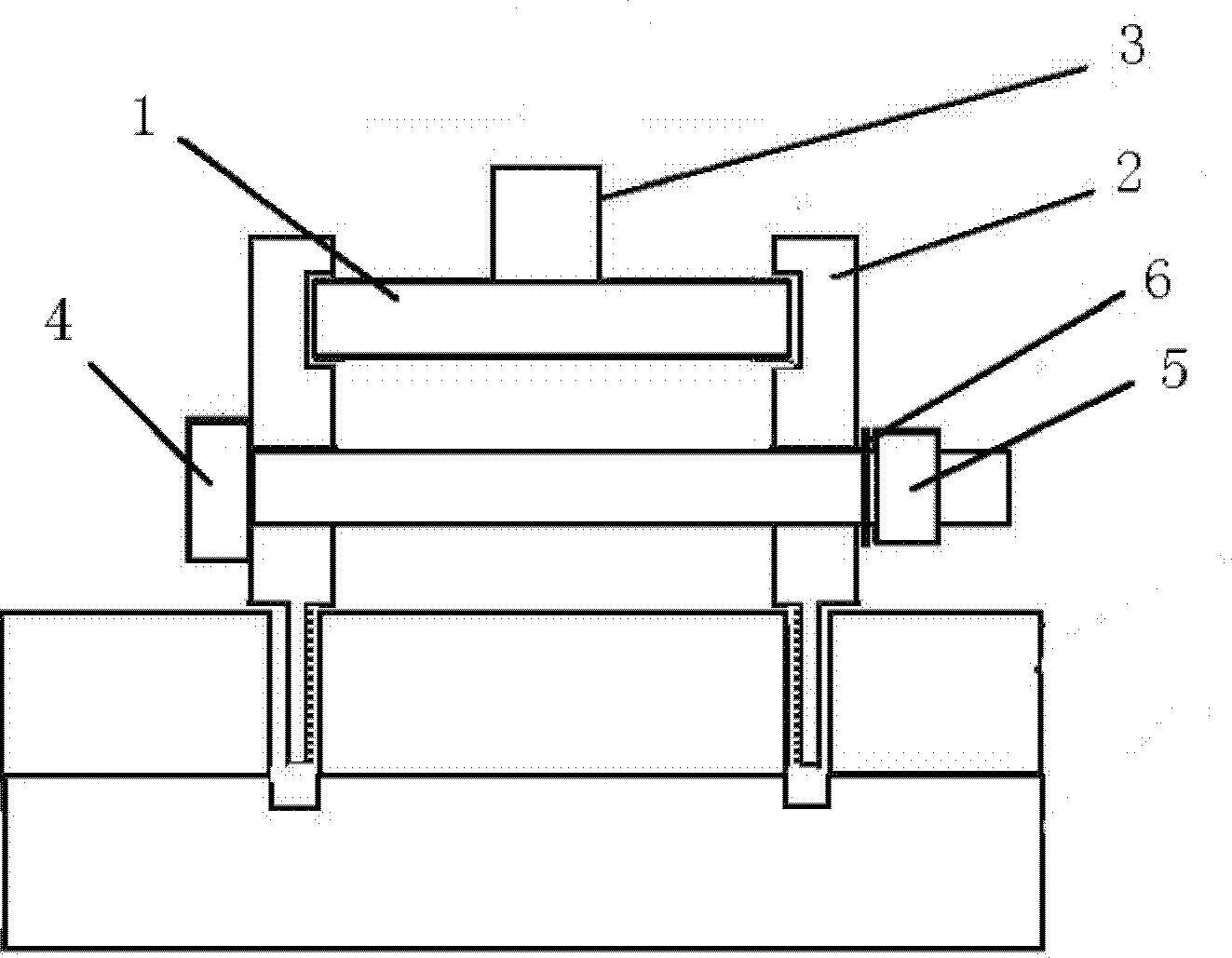

[0055] A fixture for testing the tensile bonding strength of a mortar surface layer and a substrate in the present invention includes a top drawing plate, fasteners and two splints; the fasteners include bolts, nuts and gaskets; wherein, the top drawing plate is 40mm ×40mm square plate, the side of the bolt contacting the splint is hemispherical.

[0056] The upper and middle parts of each splint are flat, with grooves on the upper part; bolt holes in the middle, and clamping parts for clamping the mortar surface at the bottom; the clamping part is flat, and its contact with the mortar surface Scores on one side. In this embodiment, the cross-sectional area of the middle part of the splint is larger than the cross-sectional area of the clamping part to form a protrusion above the clamping part.

[0057]When the detection fixture of the present invention is in use, the clamping part clamps the mortar surface layer, the protrusion above the clamping part is stuck on the sur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com