Cable flame-retardant combustion test device based on automatic control of computer

A combustion test and computer technology, applied in the direction of using combustion for chemical analysis, etc., can solve problems such as time-consuming and labor-intensive, difficult to control adjustment, affected by human factors, etc., to achieve high test efficiency, precise control of the test process, and accurate and reliable test results Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

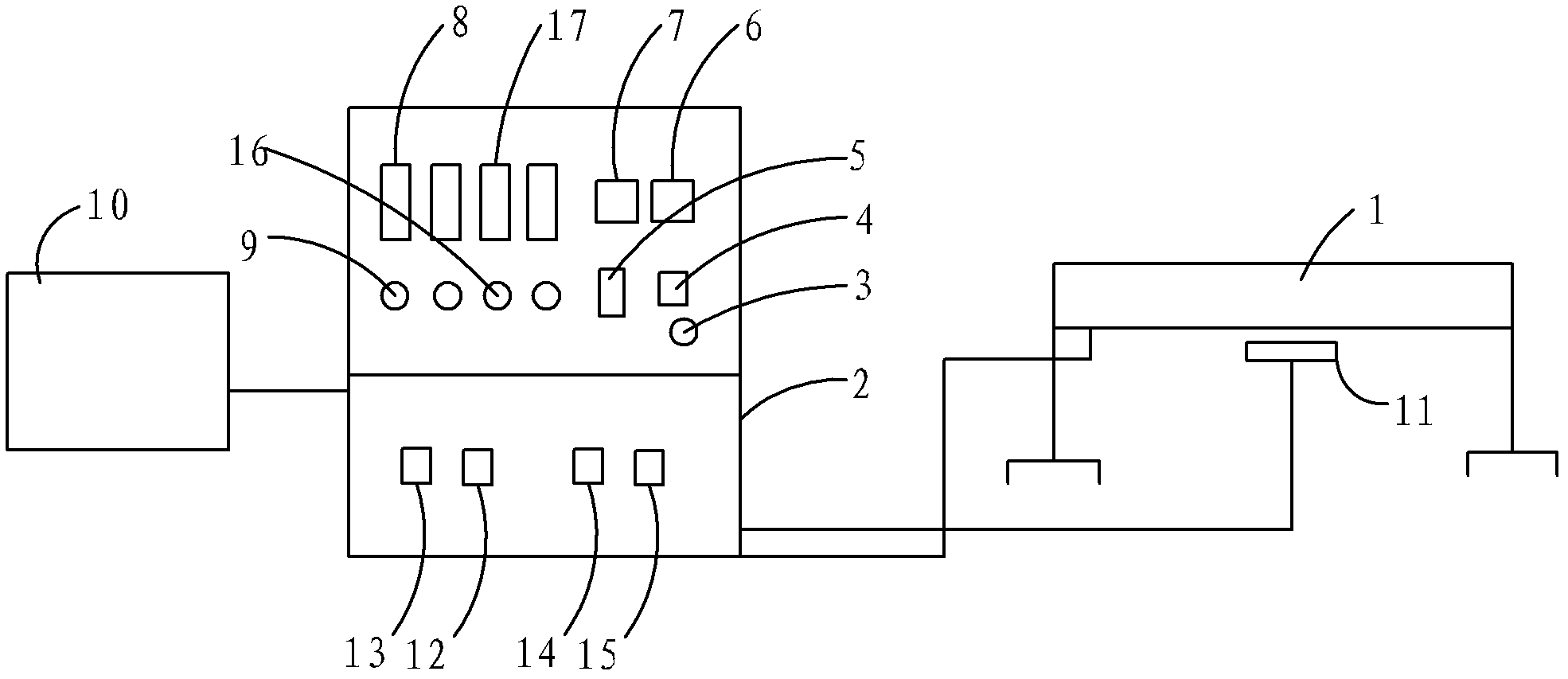

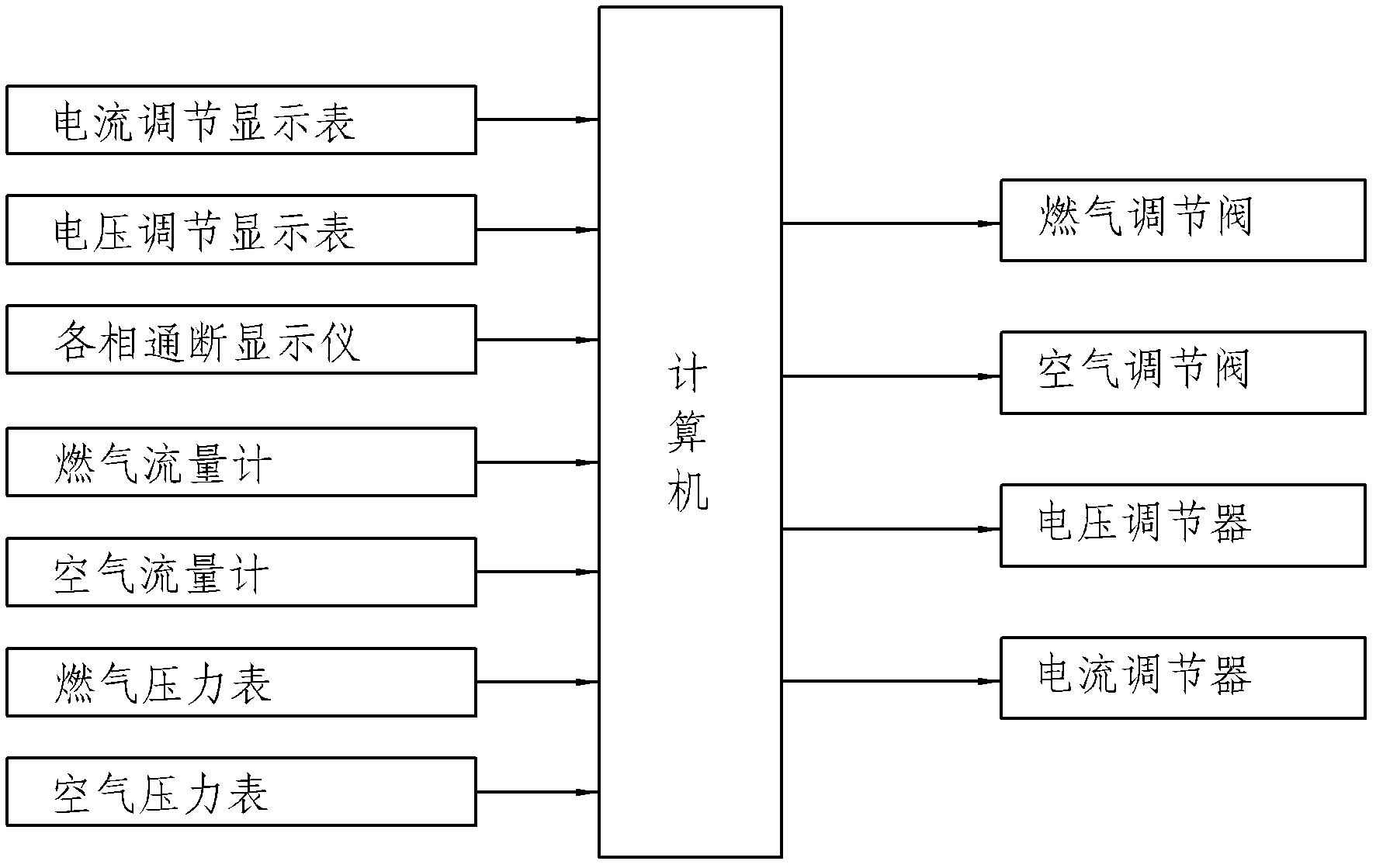

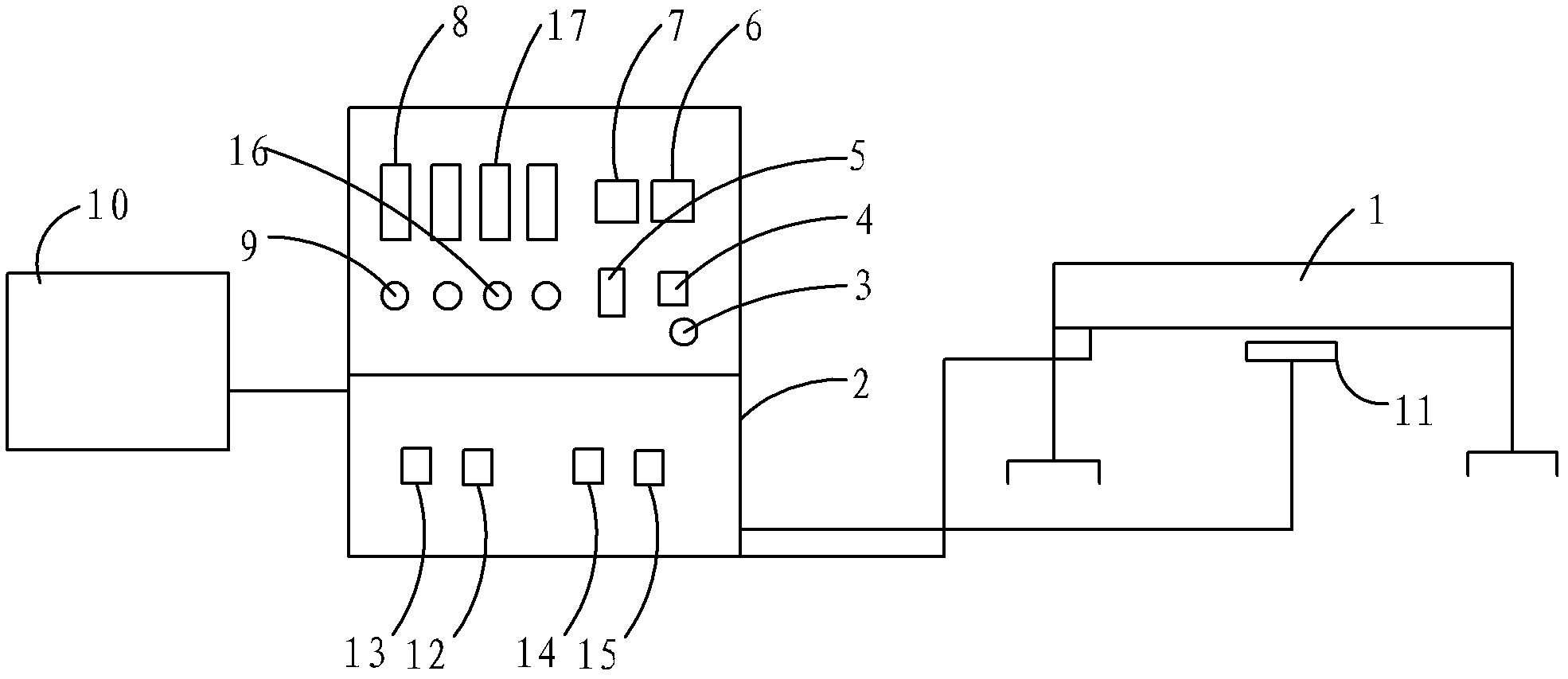

[0019] Such as figure 1 , figure 2 As shown, the cable flame-retardant combustion test device based on computer automatic control includes an electrical control cabinet 2, a power supply, a test sample rack 1 and a burner 11 arranged in a closed room; a main power switch 3 is arranged on the electrical control cabinet; the cable resistance The combustion test device also includes a computer 10 installed with control software.

[0020] The burner 11 is connected with a gas supply pipeline and an air supply pipeline, the gas supply pipeline is provided with a gas regulating valve 13, and the air supply pipeline is provided with an air regulating valve 14; the electrical control cabinet 2 is provided with a voltage regulator 14. Voltage regulation display meter 5, current regulator 15, current regulation display meter 4, each phase on-off display device 7, each phase safety device 6, gas pressure gauge 9, air pressure gauge 16, gas flow meter 8, air flow meter 17.

[0021] Bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com