Quick-change grabbing fixture type fuel rod remote grabbing tool

A fuel rod and remote technology, which is applied in the direction of manufacturing tools, reactor fuel elements, nuclear engineering, etc., can solve the inability to quickly replace the tool gripper, waste of space and cost, and the inability to grab the side of the fuel rod or cut it off and other problems, to achieve the effect of adjustable clamping force, saving space and cost, and fast connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

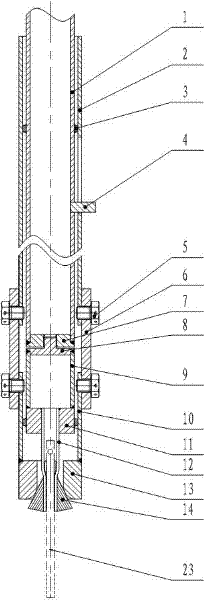

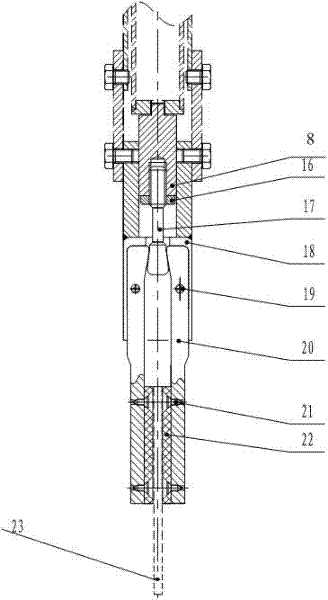

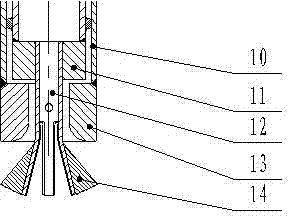

[0025] Such as figure 1 , 2 As shown in , 3, the quick-change grip type fuel rod remote gripping tool of the present invention includes a tool shaft, and a gripper A or gripper B connected with the tool stem.

[0026] The tool bar includes: an inner connecting pipe 1, an outer connecting pipe 2, a positioning ring 3, a position indicating pin 4, a connecting nut 5, a connecting sleeve 6, and a connecting block 7. The inner connecting pipe 1 is arranged inside the outer connecting pipe 2, and the outer connecting pipe 2 is connected with the gripping head A or the gripping head B through the connecting sleeve 6, and the inner connecting pipe 1 is connected with the gripping head A or the gripping head B through the connecting block 7.

[0027] The tool bar is the carrier of two kinds of grippers, that is, the carrier of gripper A or gripper B, so that the operator can operate the gripper from a long distance. At the same time, there is a quick-change joint mechanism on the too...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com