Linear platform of double-shaft floating stator

A linear platform and stator technology, applied in electrical components, semiconductor/solid-state device manufacturing, circuits, etc., to achieve the effect of improving positioning accuracy, avoiding impact, and improving positioning accuracy and measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The dual-axis floating stator linear platform of the present invention will be further described in detail below in combination with preferred embodiments.

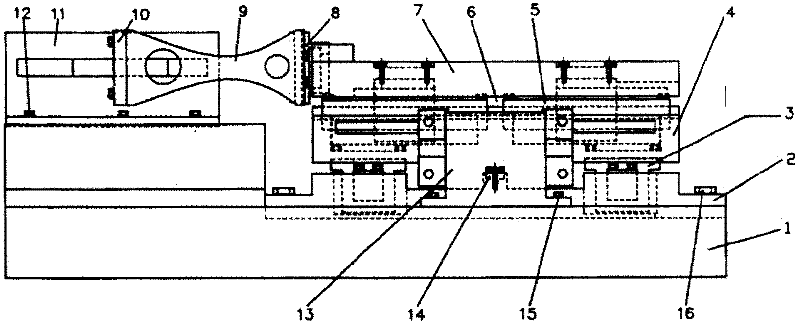

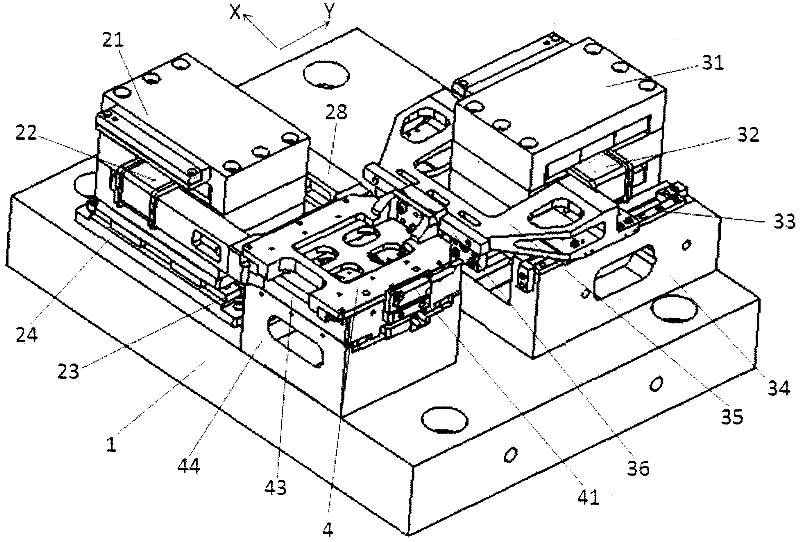

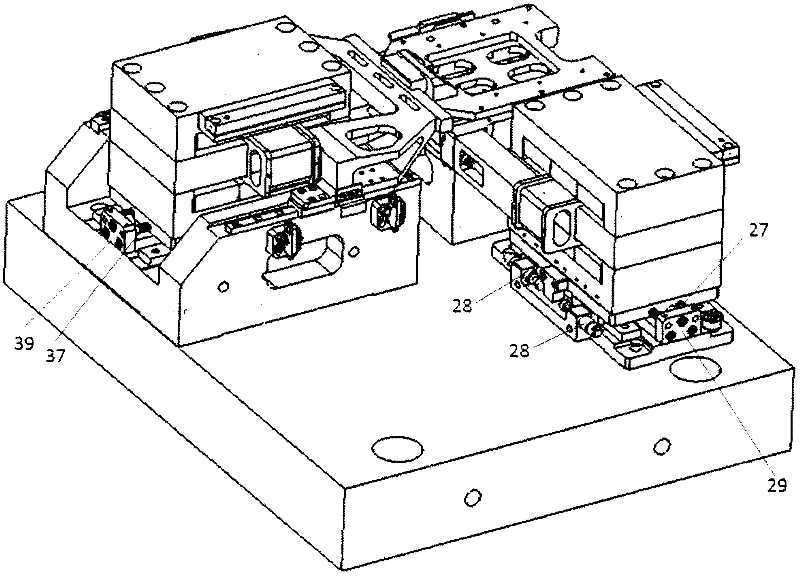

[0020] see figure 2 The shown two-axis floating stator linear platform includes a base 1 on which a driving device in a first direction and a driving device in a second direction are fixed, and is connected with the driving device in the first direction and the driving device in the second direction. Workbench 4 to which the device is attached. When the driving motor in the first direction driving device and the second direction driving device drives the workbench 4 to move, the first direction driving motor stator and the second direction driving motor stator move along the opposite direction of the movement direction of the workbench 3 , to buffer the reverse force caused by driving the table 3, so that the reaction force does not cause impact on the base 1, thereby affecting the positioning accuracy.

[0021]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com