Welding-free screw lamp holder

A screw base and shrinking technology, applied in discharge lamps, incandescent lamps, incandescent lamp parts and other directions, can solve the problems of easy snap-off and shortened product life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

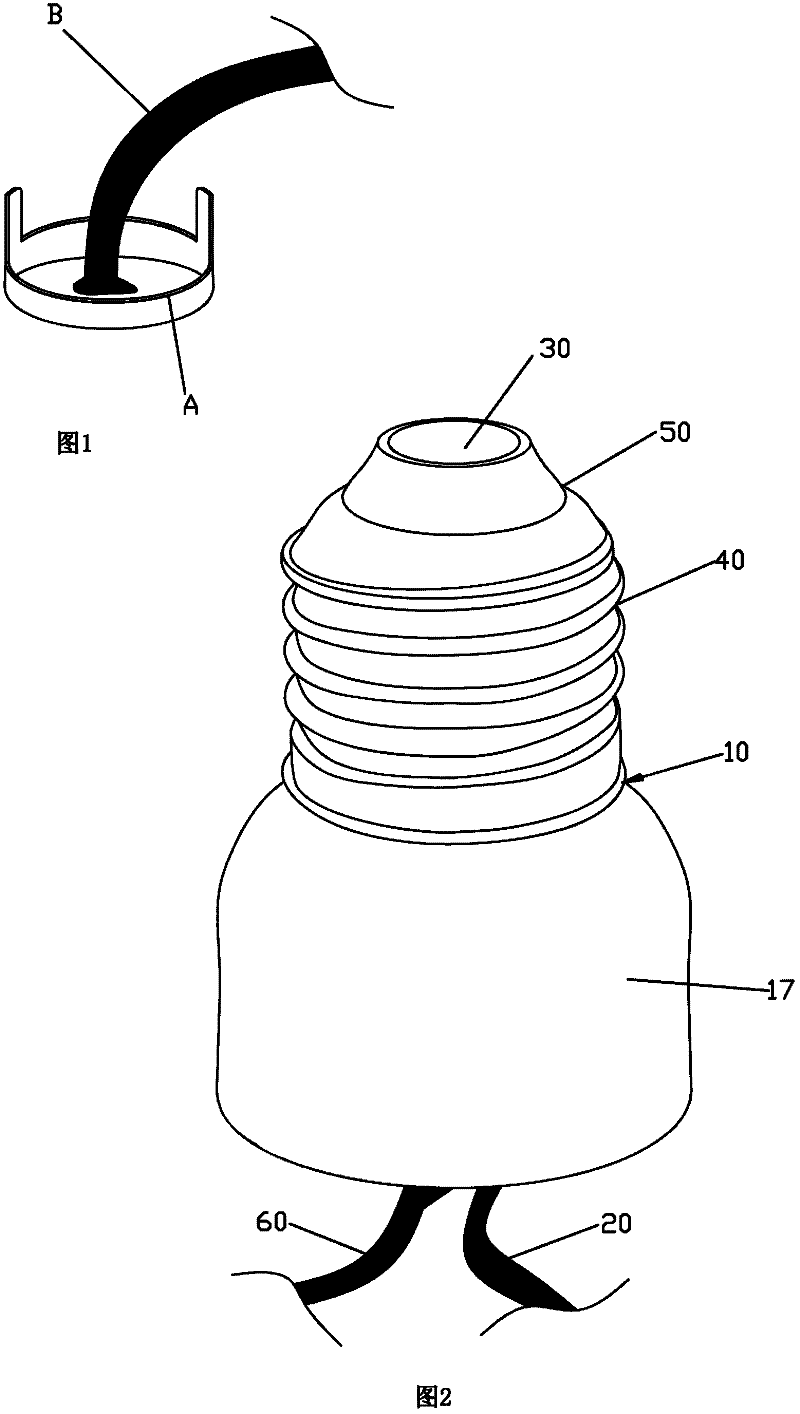

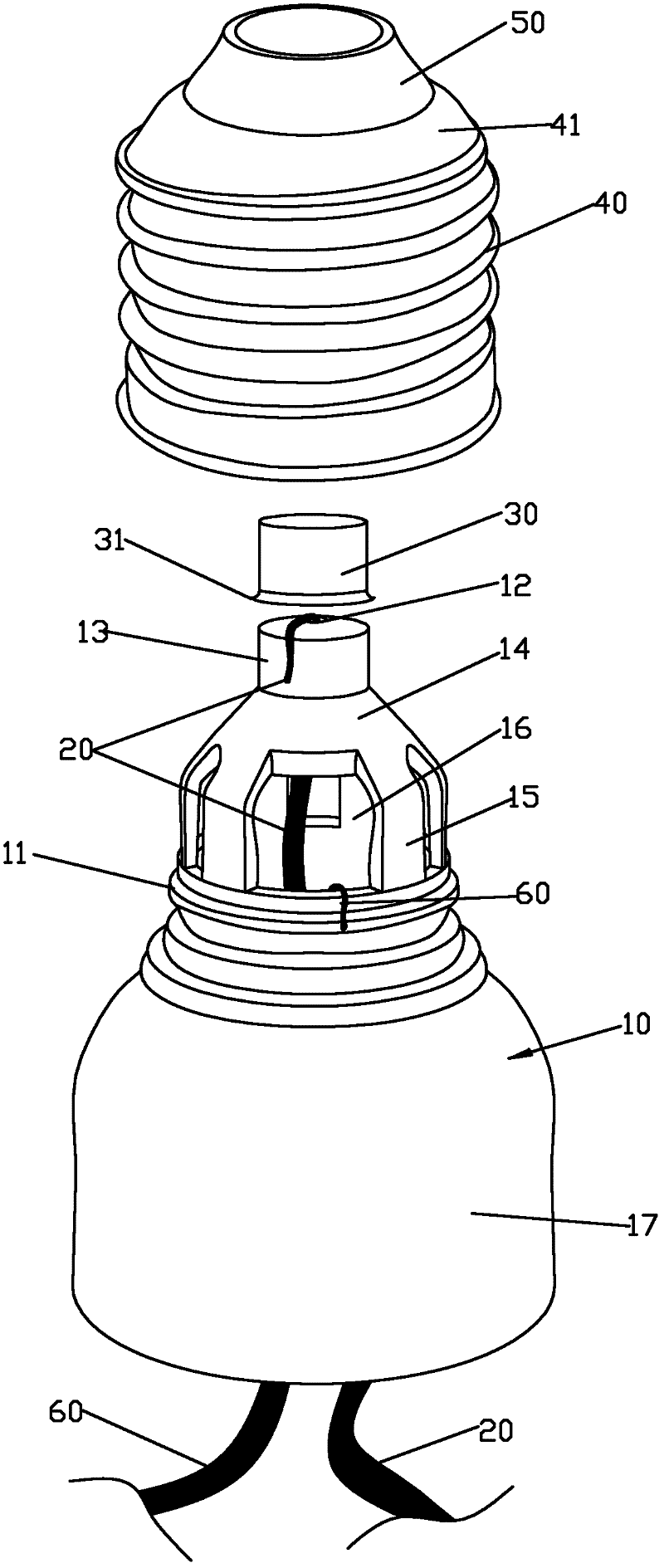

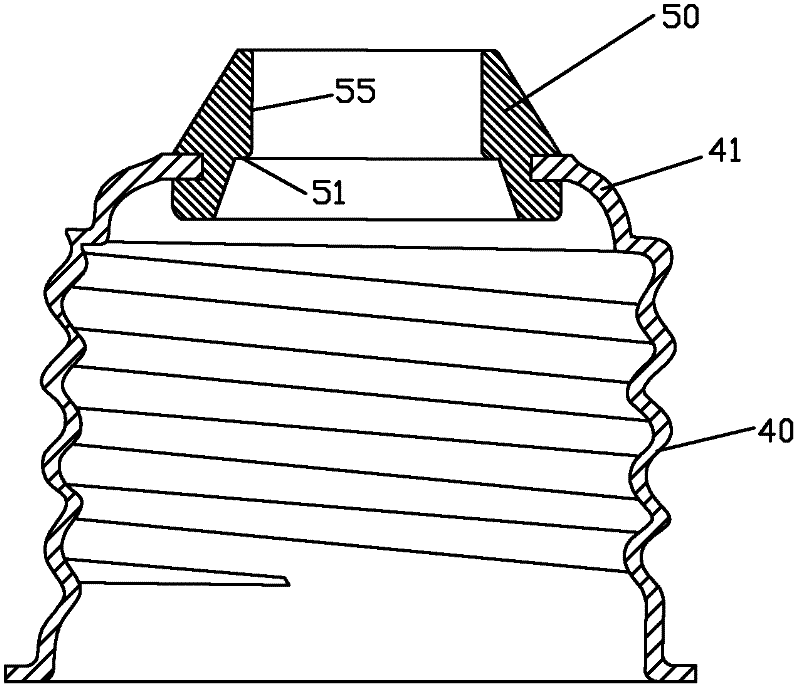

[0040] Please check figure 2 , image 3 and Image 6 , a welding-free screw lamp cap, which includes an insulating base 10, a first lead 20, a conductive cap 30, a metal threaded shell 40, an insulating sleeve 50 and a second lead 60.

[0041] The insulating seat 10 is provided with an external thread section 11 , a solid cap seat 13 with a first through hole 12 and a rotary section fixed between the external thread section 11 and the solid cap seat 13 . The insulating seat is provided with a second through hole penetrating inside and outside. In this embodiment, the second through hole 16 is provided in the rotary section, but it is not limited thereto, and may also be provided in the external thread section 11 as required. In this embodiment, the rotary section includes a circular platform section 14 and a fixed section 15, the outer peripheral edge of the circular platform section 14 is fixed on the external thread section 11 through the fixed section 15, and the fixed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com