Double-path laser power supply high-voltage isolation device and realization method thereof

A laser power supply and high-voltage isolation technology, applied in excitation methods/devices, adjusting electrical variables, instruments, etc., can solve the problems that laser power supplies cannot be used with laser tubes and cannot be completely isolated, and achieve reliable and effective sampling and high-voltage isolation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

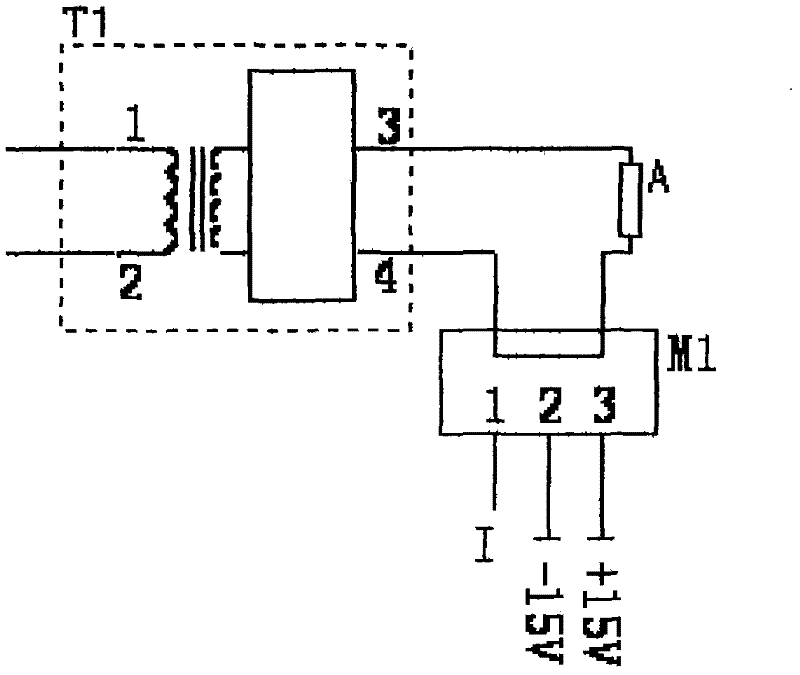

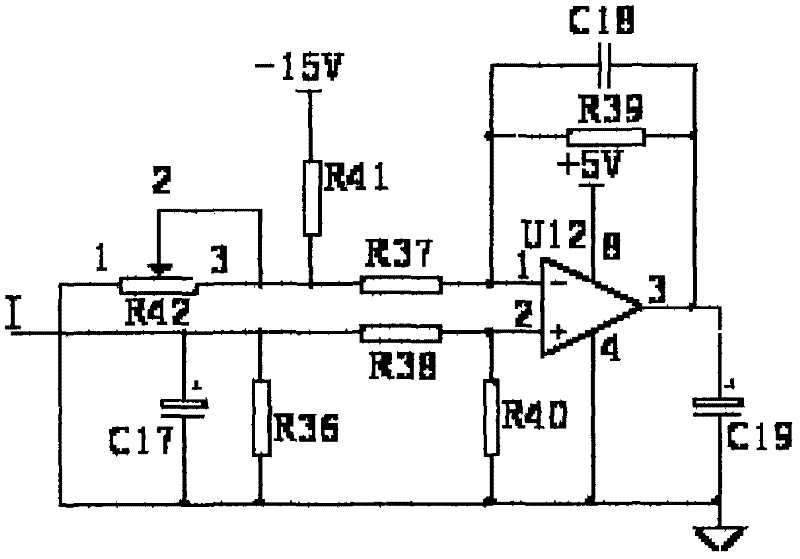

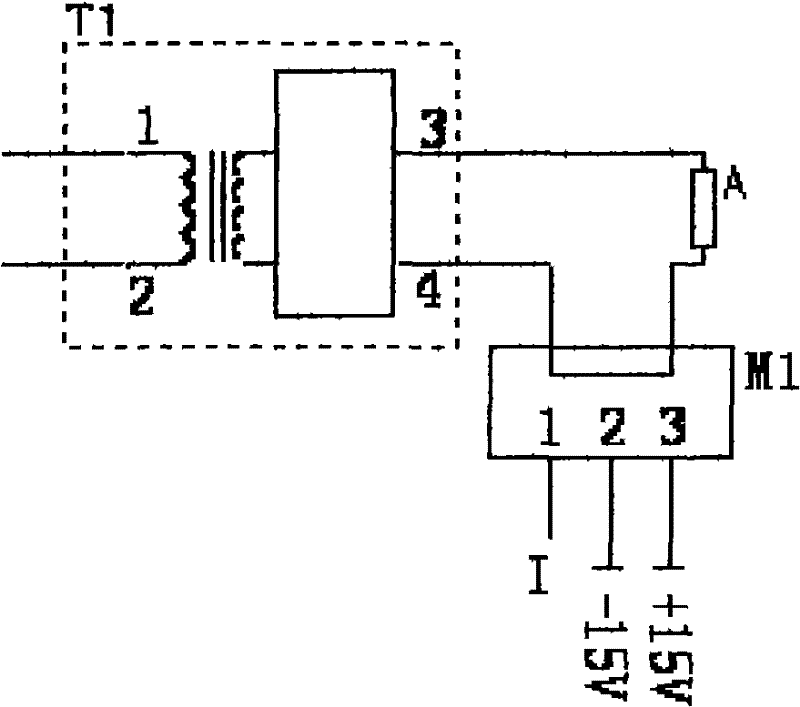

[0014] root tree Figure 1-Figure 2 A dual-path laser power supply high-voltage isolation device of the present invention includes: a high-voltage current sampling circuit and a current feedback amplification circuit.

[0015] The high-voltage current sampling circuit includes that pin 3 of the high-voltage pack T1 (high-voltage output positive end) is connected to the anode of the laser tube A with a high-voltage insulated wire, and pin 4 (high-voltage output negative end) of the high-voltage pack T1 is connected with a high-voltage insulated wire The through hole passing through the Hall current sensor M1 is connected to the cathode of the laser tube A. The Hall current sensor M1 uses a non-contact sensor of model LA50-P. Pin 1 of Hall current sensor M1 outputs high-voltage sampling current, pin 2 is connected to -15V power supply, and pin 3 is con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com