Corn directional seeding device

A corn and seed cutting technology, applied in sowing, interval-type quantitative sowing machinery, climate change adaptation, etc., can solve problems such as inconvenient transportation and operation, large size of carrier seed blocks, and difficulty in actual production, and achieve operational resistance. The effect of reducing, strict plant spacing, and improving uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

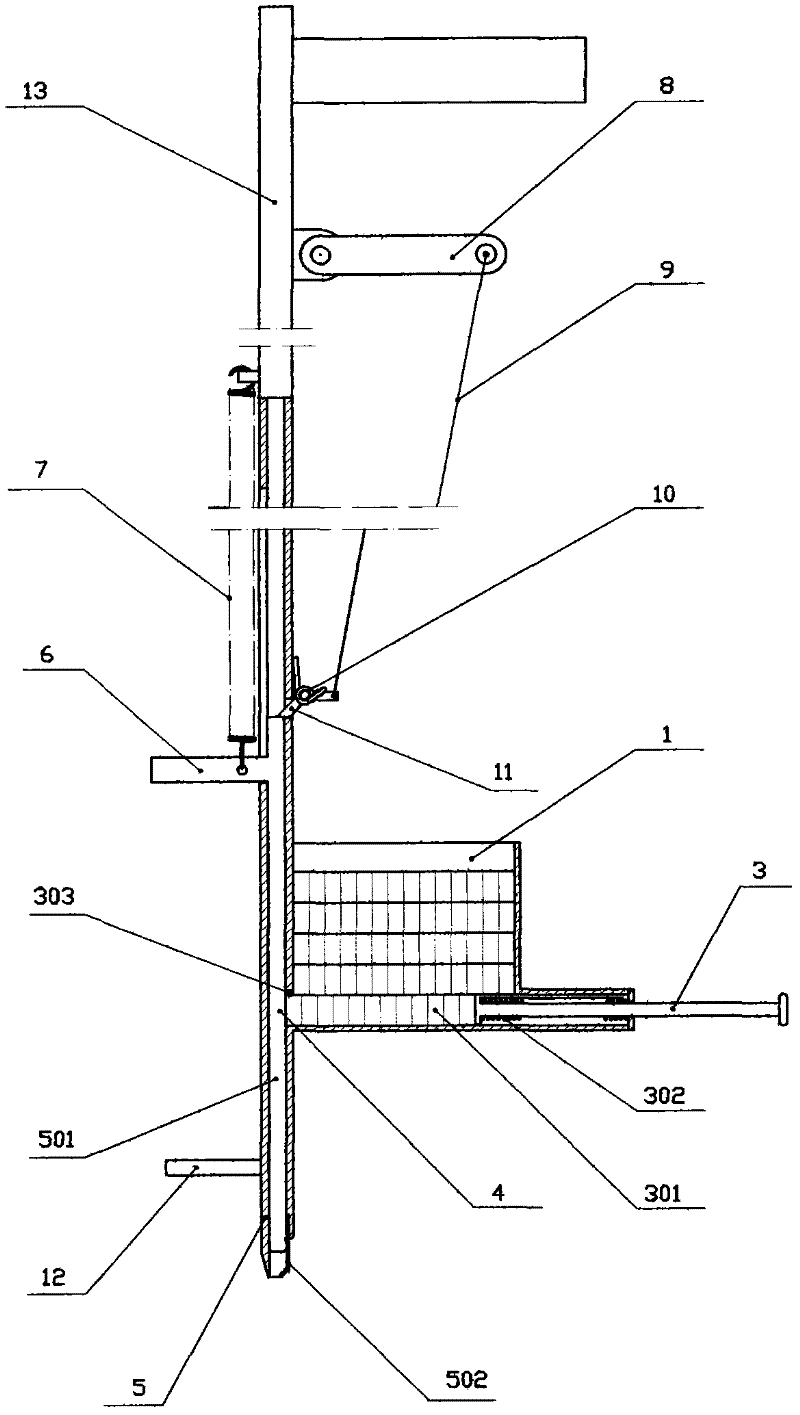

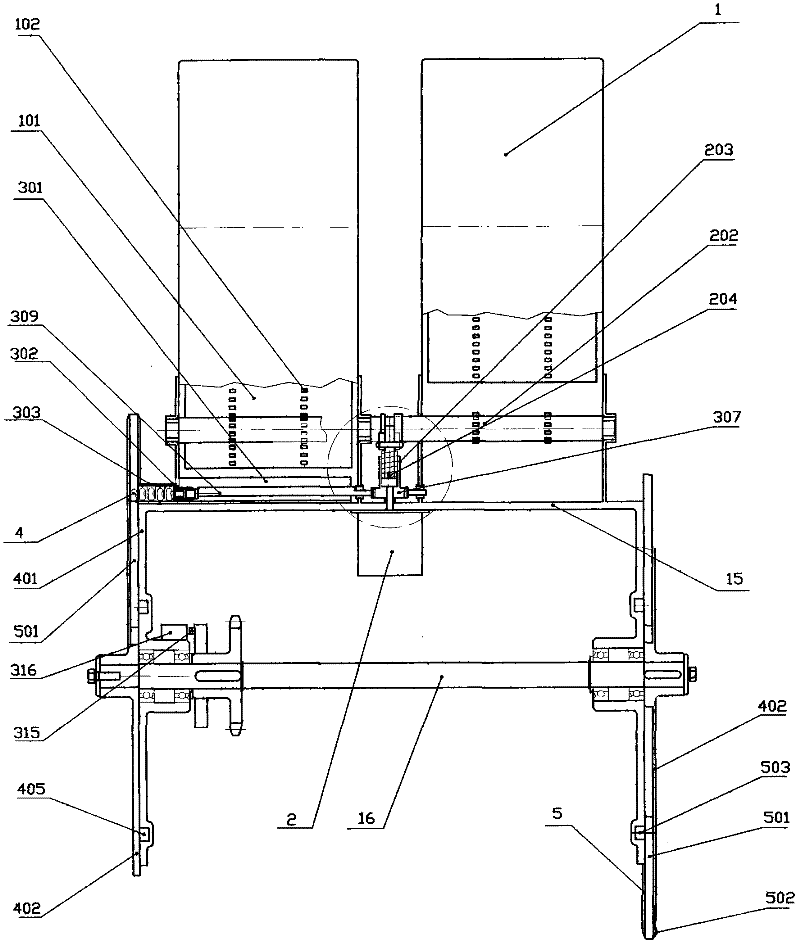

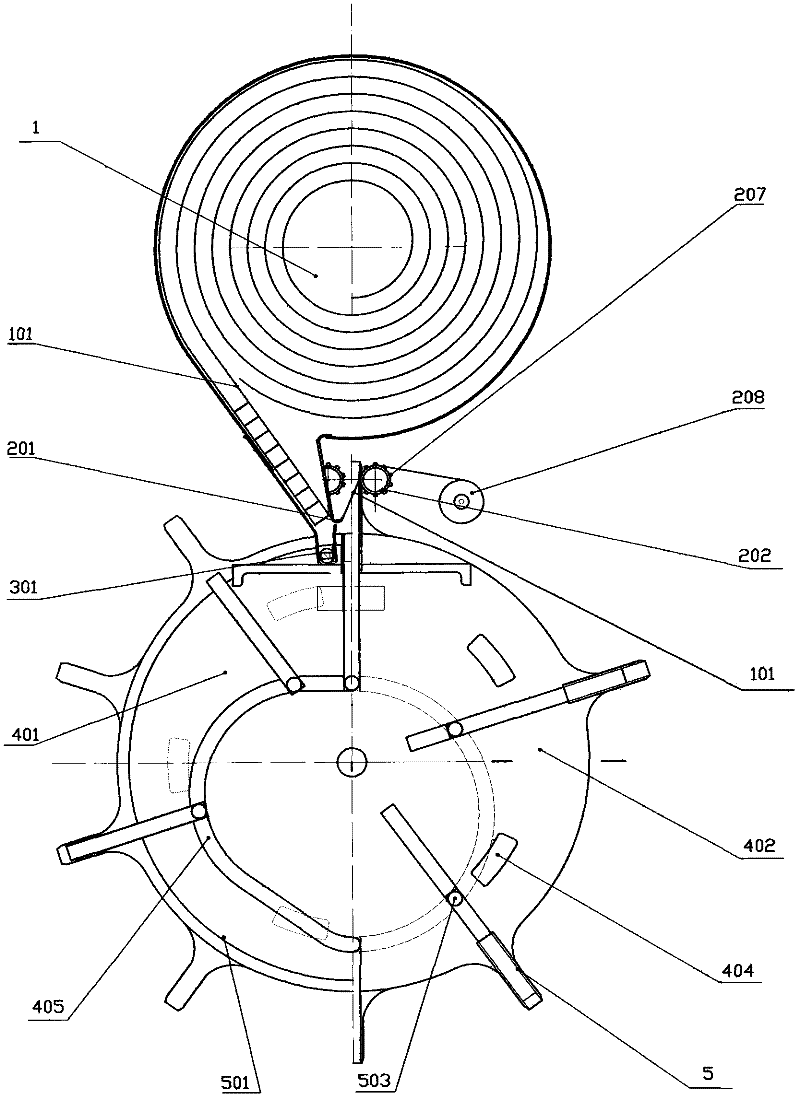

[0031] combine figure 1 Further description will be made for the manual directional corn inserter of one of the embodiments of the present invention. The seed strip box 1 is equipped with specially processed corn seed strips, which are arranged in sequence according to the axial direction of the corn seeds on the ear and bonded into the seed strips. The seed strips are based on the four characteristics related to the germ surface of the seeds in the seed strips. The same feature side among the sides is installed in the kind barrel box 1 in order for the reference to be parallel. Kind of bar box 1 below is horizontal kind of bar groove 301, and the kind of pushing rod 3 in kind of bar groove 301, pushing kind of spring 302 form and pushes kind of mechanism. The seed bar in the seed bar box 1 falls into the seed bar groove 301 at the bottom, and the seed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com