Disc type sword bean sheller

A shelling machine and sword bean technology, applied in the fields of application, food processing, food science, etc., can solve the problems that cannot meet the needs of industrialization and commercial production, hinder the development of sword bean industrialization, and the seeds are difficult to move, etc. Achieve the effect of realizing batch shelling processing, broad industrial application prospects and maintaining plasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

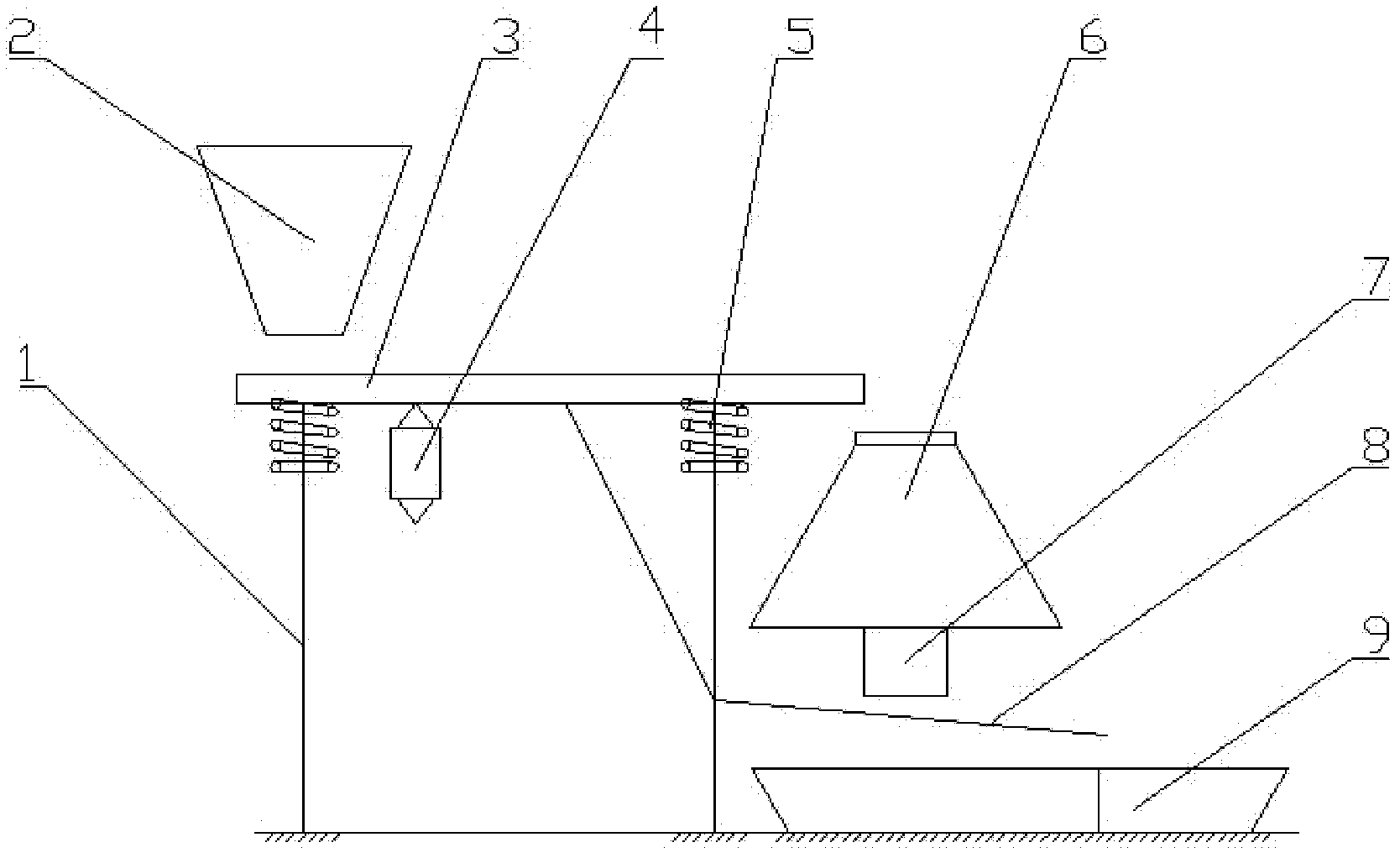

[0035] Such as figure 1 As shown, the disc-type sword bean shelling machine includes frame 1, feeding hopper 2, vibrating bed 3, vibrating motor 4, damping spring 5, shelling conical disc mechanism 6, main driving mechanism 7, vibrating separator Net 8 and receiving box 9.

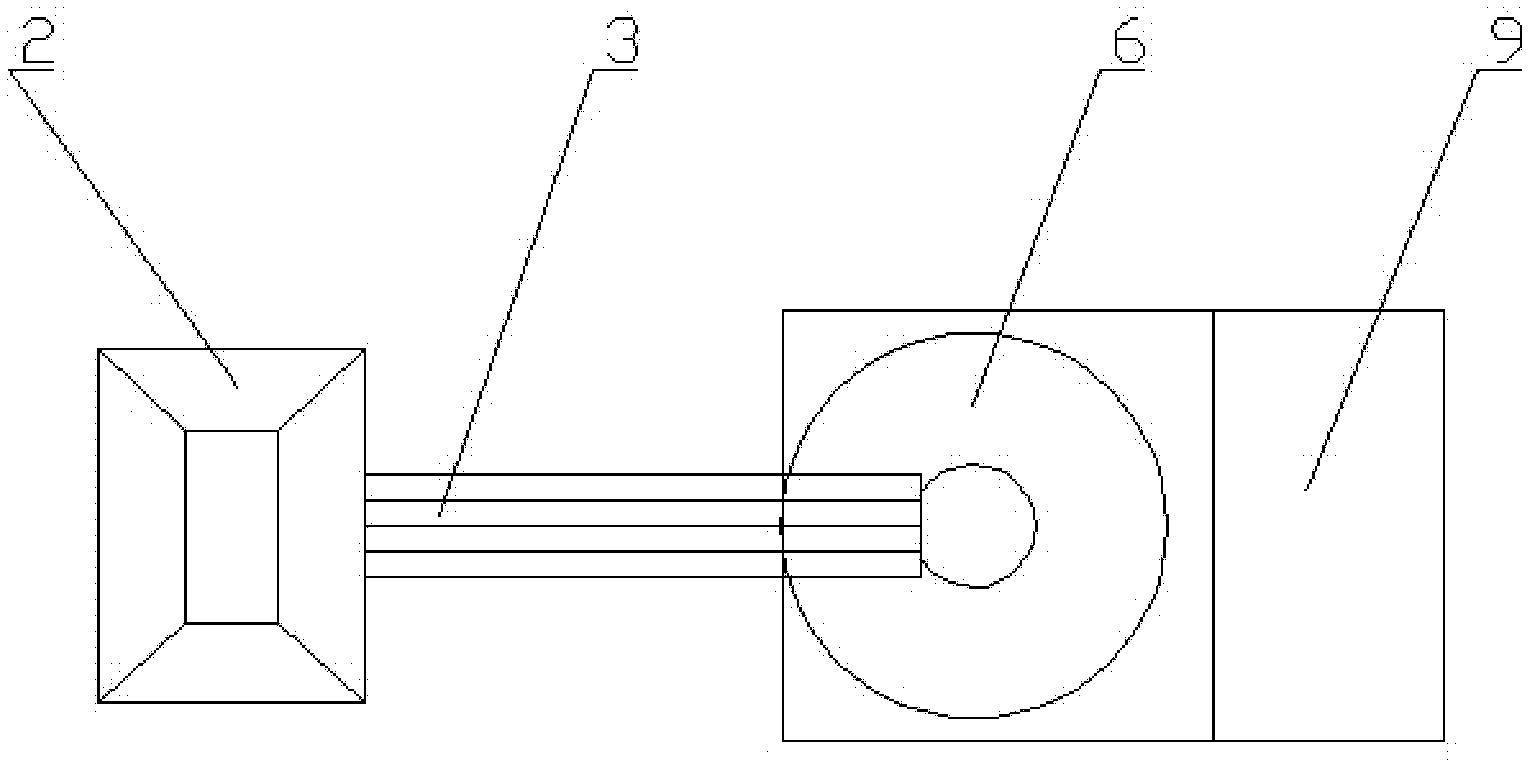

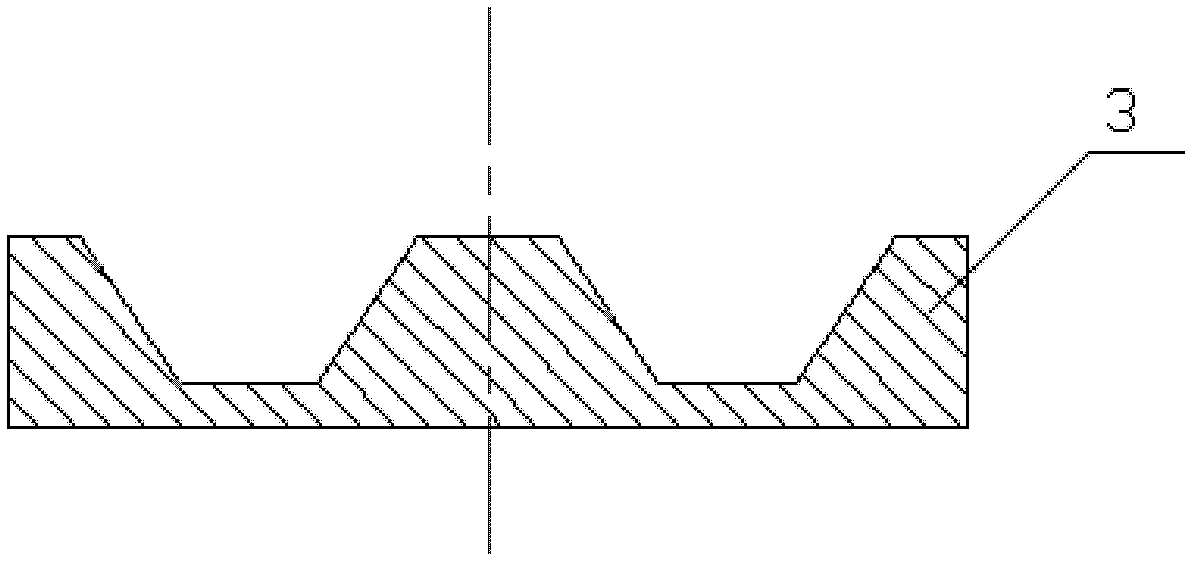

[0036] The vibrating bed 3 is fixed on the frame 1 through the damping springs 5 below its two ends, and is provided with feeding guide grooves arranged in parallel and spaced intervals along the longitudinal direction; as figure 2 with image 3 As shown, the cross-sectional shape of the feeding guide groove is V-shaped, and its tail end is located above the shelling cone mechanism 6 .

[0037] The feed hopper 2 is fixed above the head end of the vibrating bed 3 ; the vibrating motor 4 is connected below the vibrating bed 3 .

[0038] Shelling cone mechanism 6 is arranged on the below of the tail end of vibrating bed 3, as Figure 4 with Figure 5 As shown, it includes an upper conical disc 10 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com