Sprinkled acid recycling device and pasting equipment of battery plates

A technology of acid rinsing and paste coating machine, applied in the direction of filtration and separation, separation methods, chemical instruments and methods, etc., which can solve the problems of affecting process efficiency, long processing cycle, and insufficient processing, so as to improve process efficiency and simplify processing methods , good environmental performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described in detail below through specific embodiments in conjunction with the accompanying drawings.

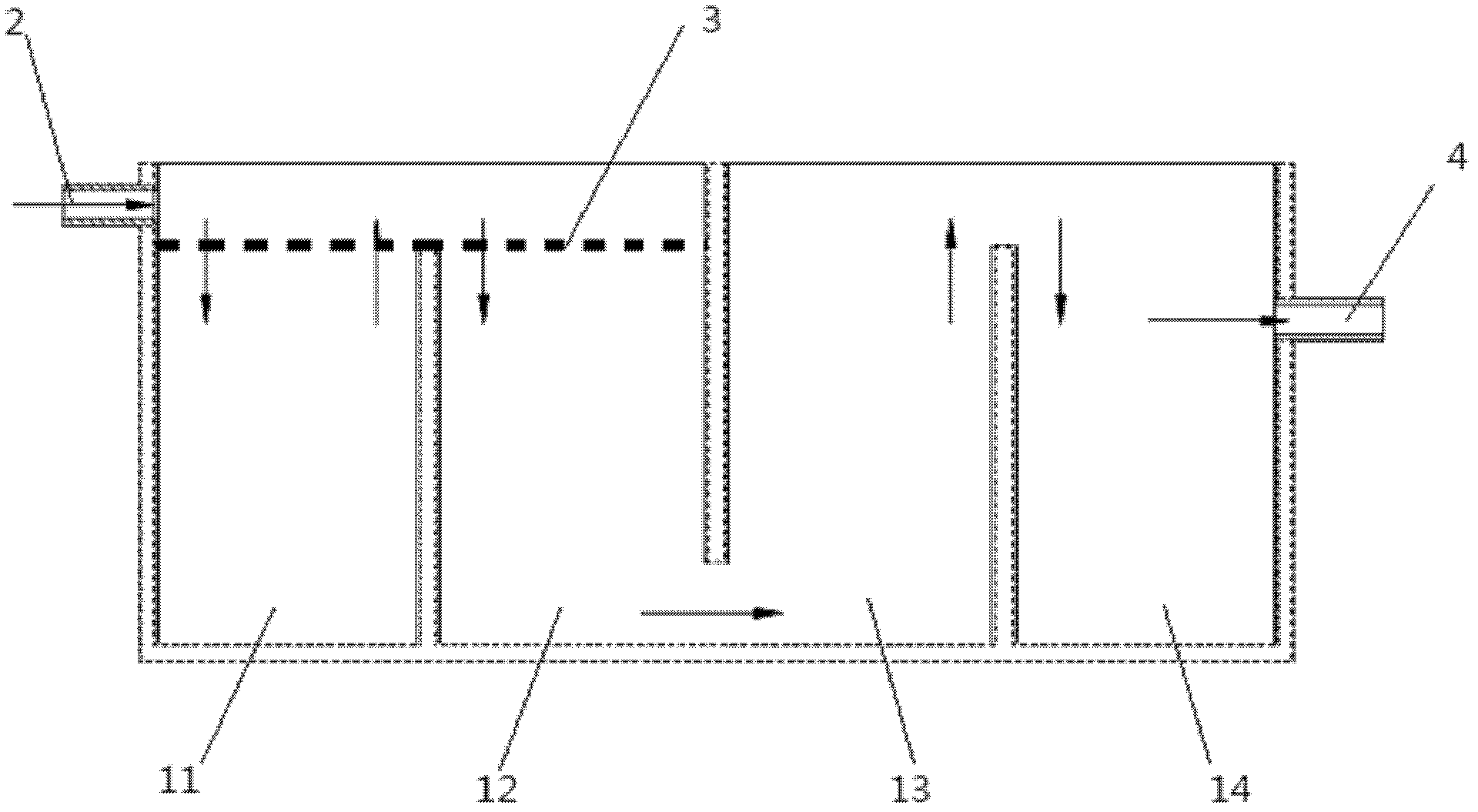

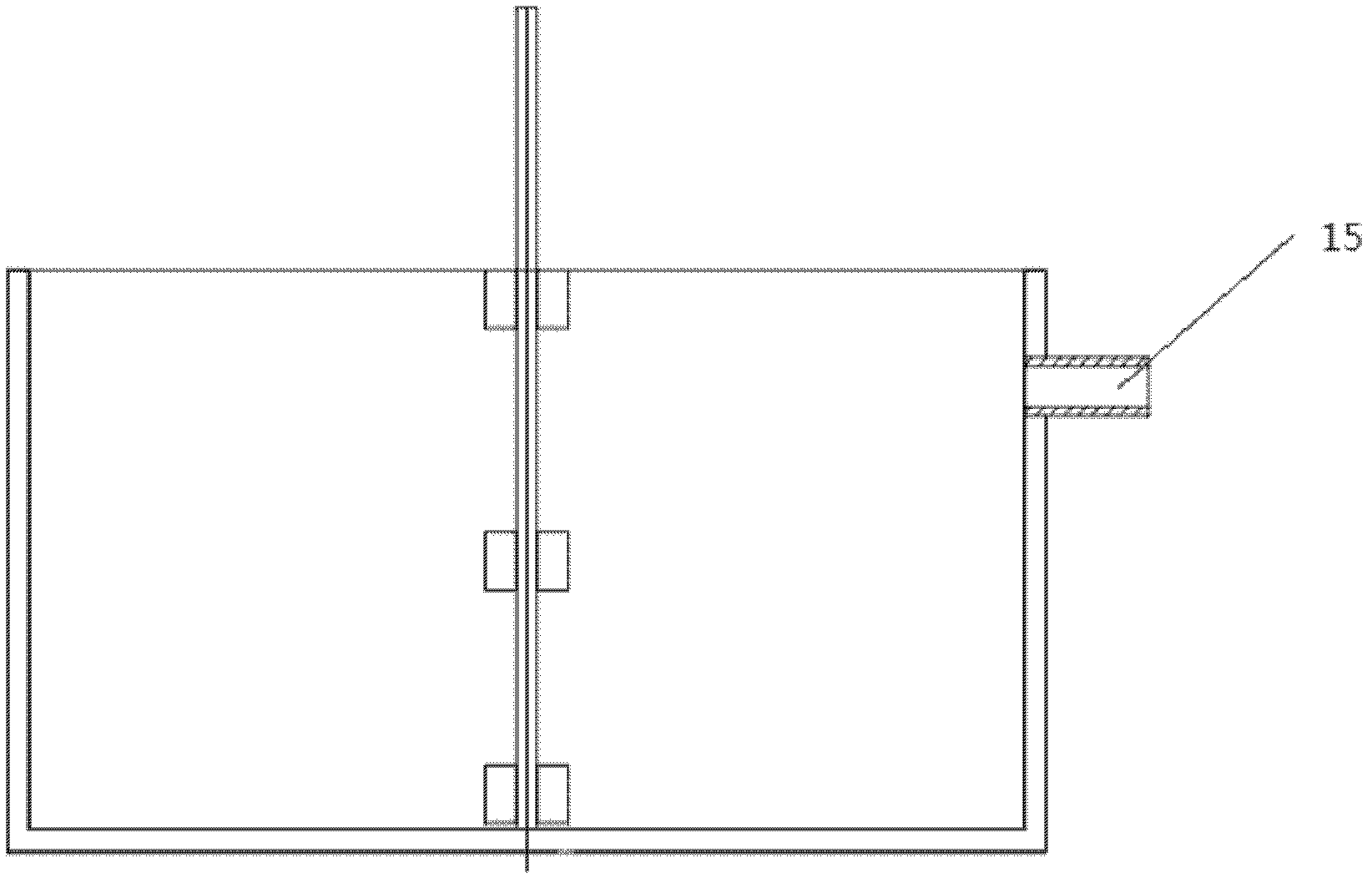

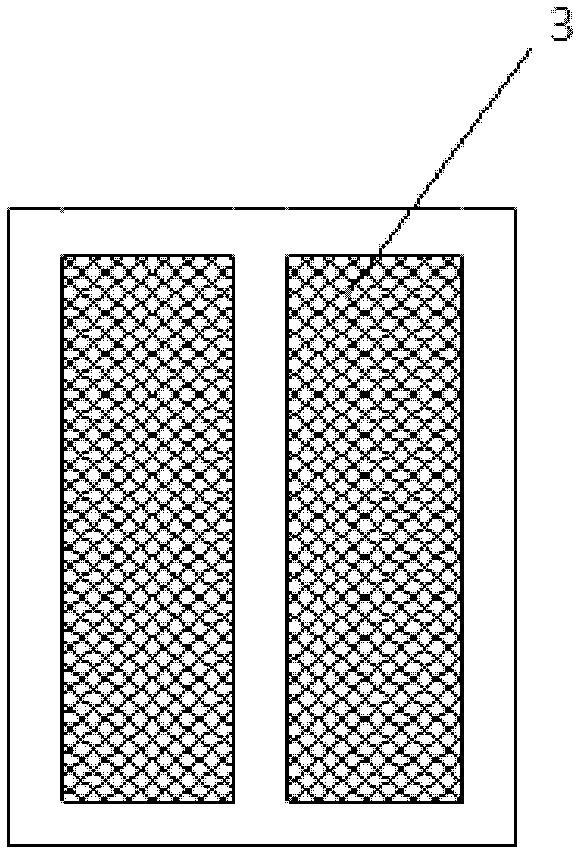

[0020] Please refer to figure 1 , figure 2 and image 3 , The acid leaching recycling device of the present embodiment mainly includes components such as a filter tank, a recovery sedimentation tank, a filter screen 3, a return pipe, an acid leaching pipe, an acid pump, and a density meter. Wherein, the filter tank and the recovery sedimentation tank are connected to each other and can be made of a barrel or tank-like container. For example, in the present embodiment, the side of the filter tank with the outlet 15 is connected to the inlet of the reclaiming sedimentation tank, the other side without the outlet 15 is connected with the acid leaching outlet of the plastering machine, and the filter screen 3 is inserted in the middle of the filter tank. The top of the filter tank is provided with an acid inlet 2, such as the acid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com