Automatic quantitative spray machine and method thereof

An automatic, casing technology, applied in chemical instruments and methods, cleaning methods and utensils, cleaning methods using liquids, etc., can solve difficult-to-clean dehydration liquid stability and quantitative control, waste of liquid resources, product quality, and unstable manual operation. It can reduce the labor intensity of personnel, realize automatic control, and save cleaning costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

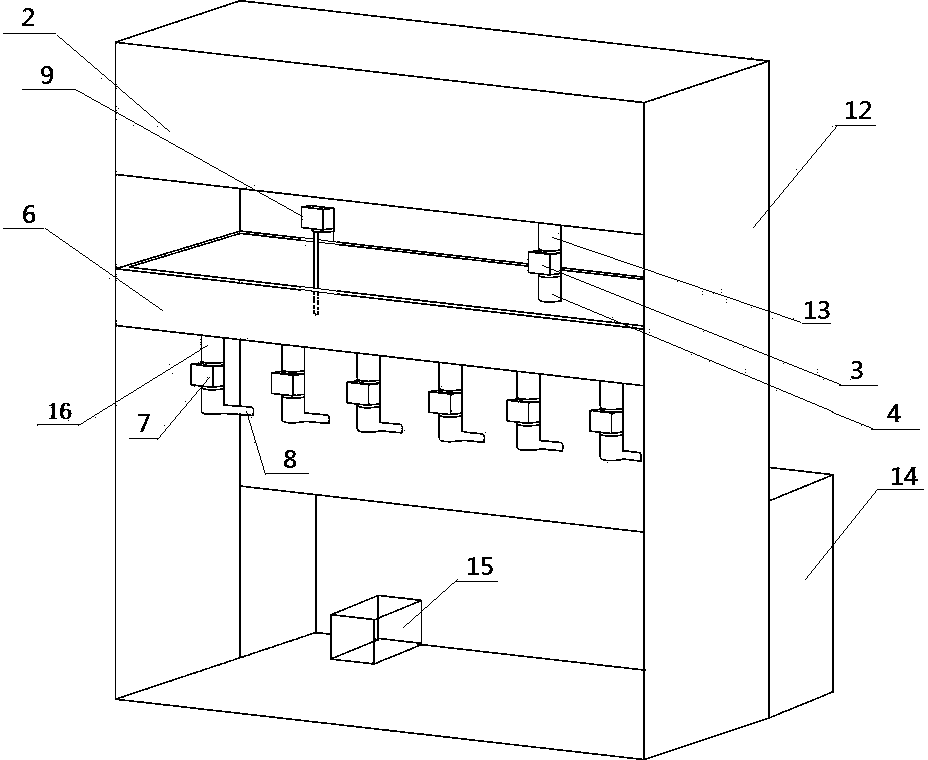

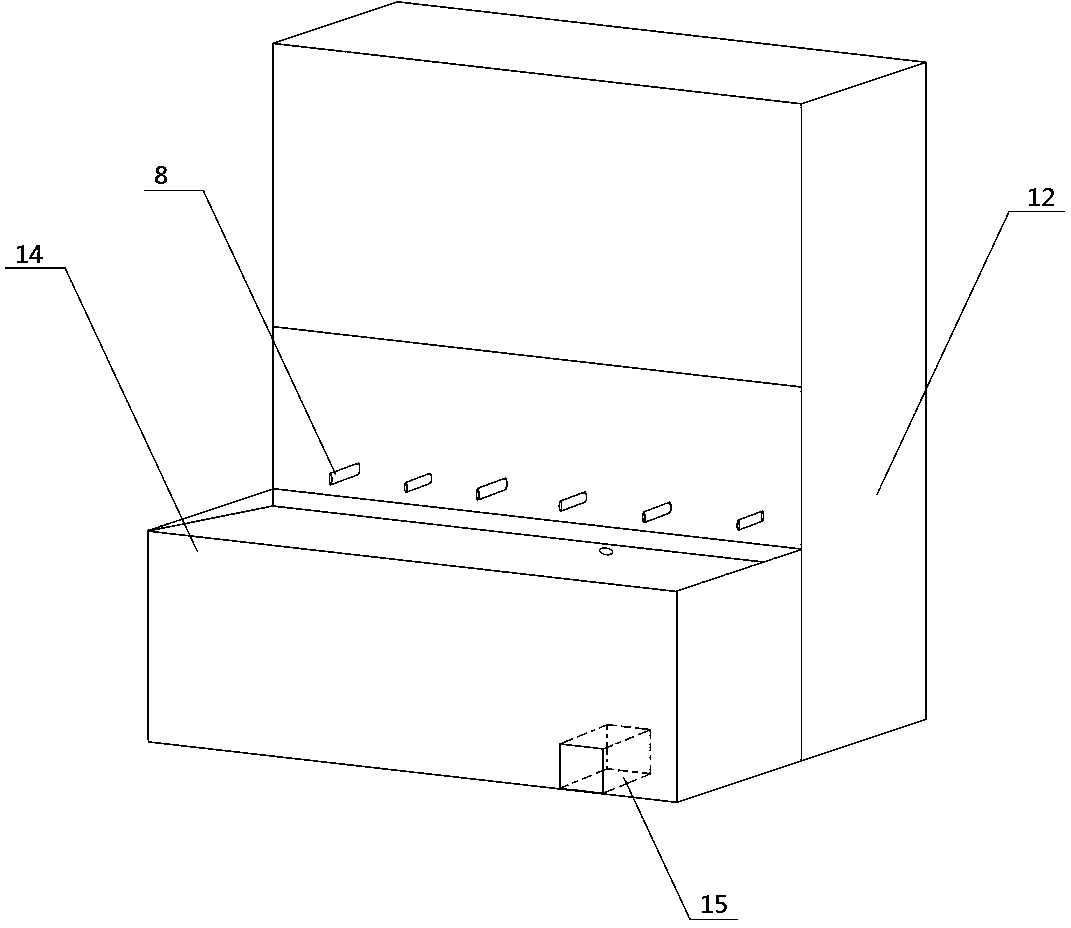

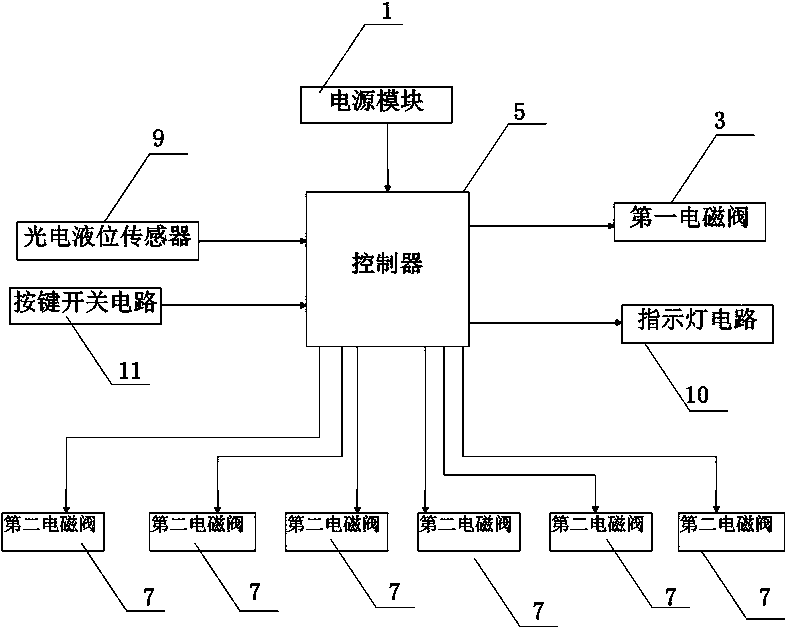

Embodiment 1

[0028] Embodiment one: if Figure 1 to Figure 3 As shown, an automatic quantitative spraying machine includes a power supply module 1 and a liquid storage tank 2, the liquid storage tank 2 is connected to the first flow guide pipe 4 through a first electromagnetic valve 3, and the first electromagnetic valve 3 The control end is connected to the first output end of the controller 5 through a relay, and a liquid delivery tank 6 is provided below the mouth of the first diversion pipe 4, and the liquid delivery tank 6 is connected to the second guide through the second electromagnetic valve 7. The control end of the second electromagnetic valve 7 is connected to the second output end of the controller 5 through a relay, and the liquid delivery tank 6 is also provided with a photoelectric liquid level sensor 9, and the photoelectric liquid The output end of the position sensor 9 is connected to the first input end of the controller 5 , and the output end of the power module 1 is c...

Embodiment 2

[0036] Embodiment two: if Figure 4 Shown, a kind of automatic quantitative spraying method based on automatic quantitative spraying machine comprises the following steps:

[0037] S1, the key switch circuit 11 sends a signal to the controller 5;

[0038] S2. The controller 5 controls the opening of the first electromagnetic valve 3;

[0039] S3. The photoelectric liquid level sensor 9 detects the height of the liquid in the liquid delivery tank 6; when it is detected that the liquid in the liquid delivery tank 6 reaches a set height, the photoelectric liquid level sensor 9 sends a signal to the controller 5; The controller 5 controls the first solenoid valve 3 to close;

[0040] S4. The controller 5 controls the opening of the second electromagnetic valve 7;

[0041] S5. When the photoelectric liquid level sensor 9 detects that the liquid in the liquid delivery tank 6 reaches a set low level, the photoelectric liquid level sensor 9 sends a signal to the controller 5; the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com