Bucket arm pressing sleeve machine

A technology of press-fitting machine and stick, which is applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of limited assembly occasions, large manpower consumption, and low production efficiency, and achieve high reliability, convenient operation, and easy assembly. high efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

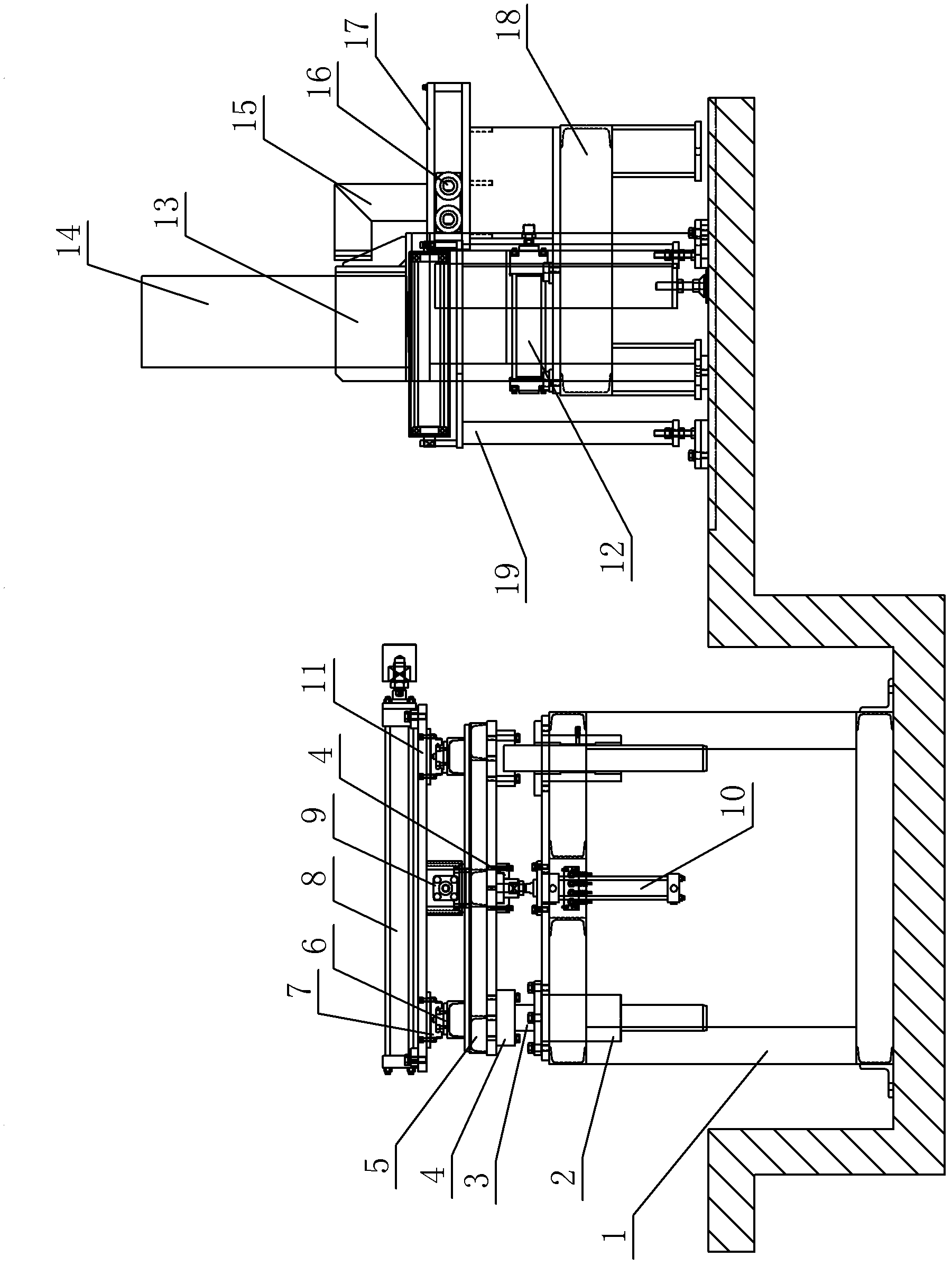

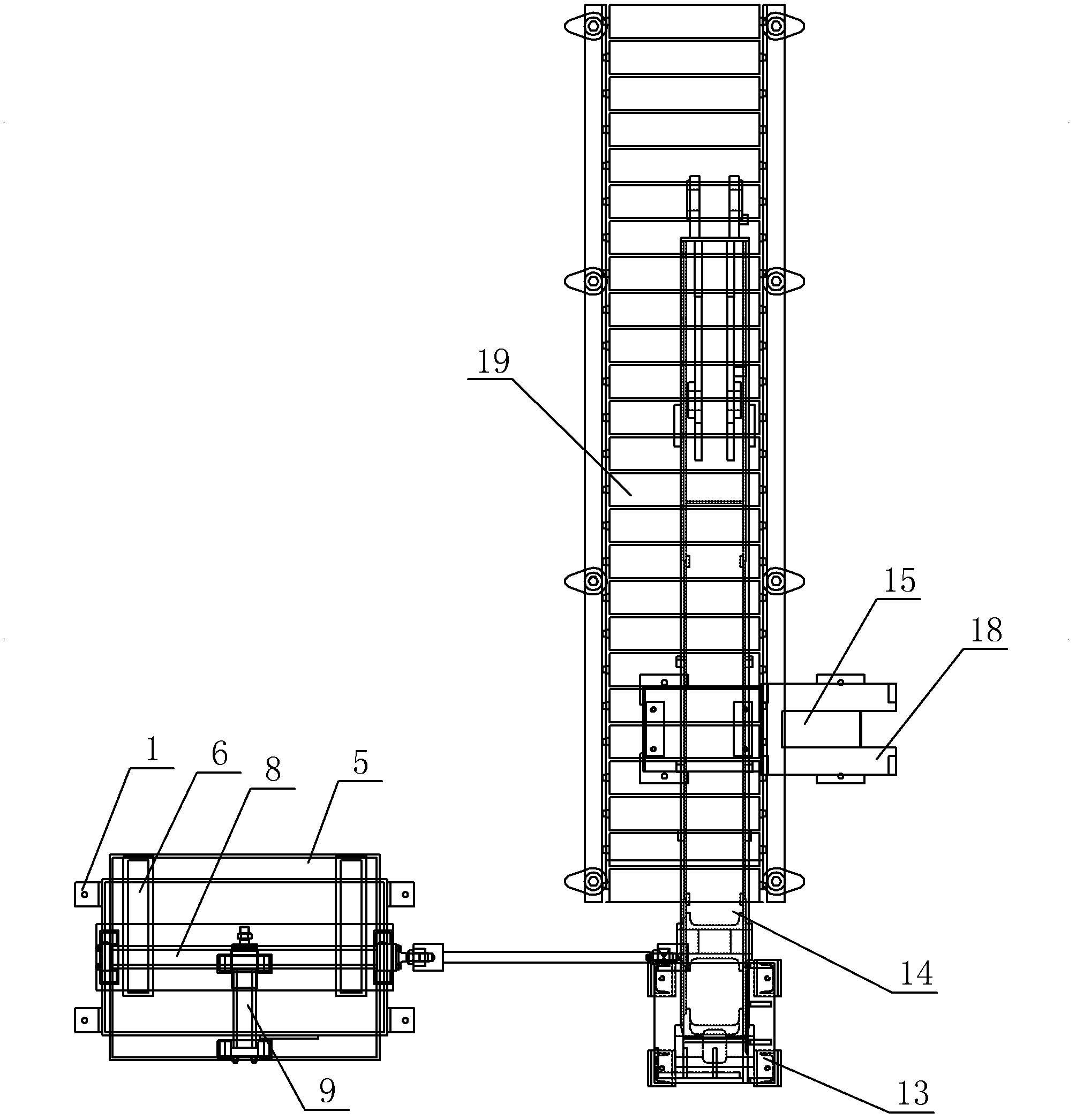

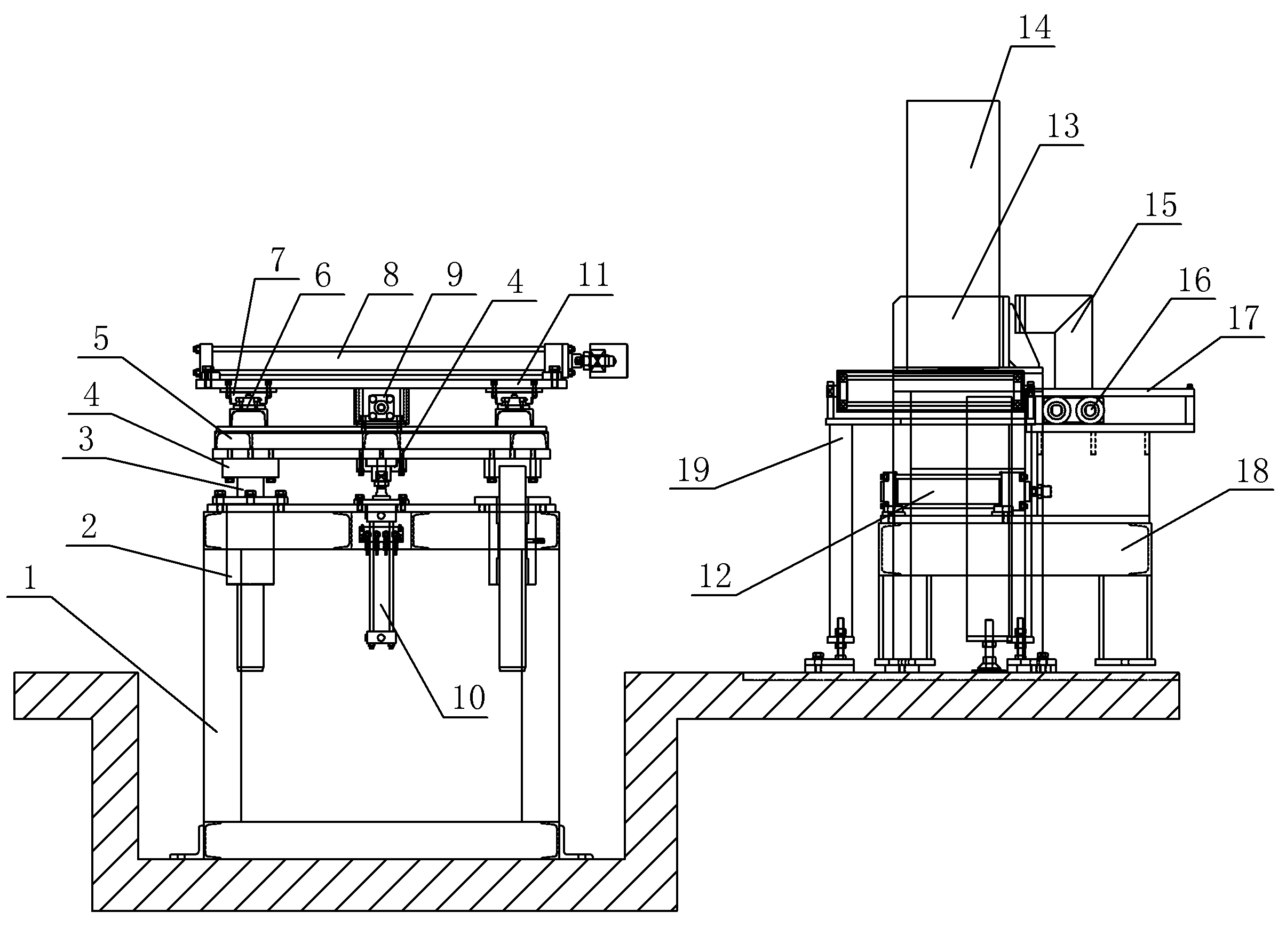

[0014] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

[0015] see figure 1 As shown, in this embodiment, a stick pressing machine includes a pressing device, a clamping device and a retaining seat. The pressing device is arranged on one side of the assembly line 19, and the clamping device is arranged in conjunction with the assembly line 19. The retaining seat 13 is arranged at the front end of the assembly line 19, and the pressure sleeve device includes a pressure sleeve frame 1 fixed on the ground through steel expansion bolts, and a jacking cylinder 10 and a sliding bearing are installed on the pressure sleeve frame 1 Sleeve 2, the propelling end of the jacking cylinder 10 is connected to the bottom surface of the jacking platform 5 through the flange 4, and the bottom surface of the jacking platform 5 is also equipped with a linear optical axis 3 ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap