Clamp structure for C-shaped ferrite magnetic core

A ferrite core and glyph technology, applied in the field of fixtures, can solve the problems of volume expansion, affecting power, and the absence of C-shaped ferrite cores, etc., and achieve the effect of simple structure and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

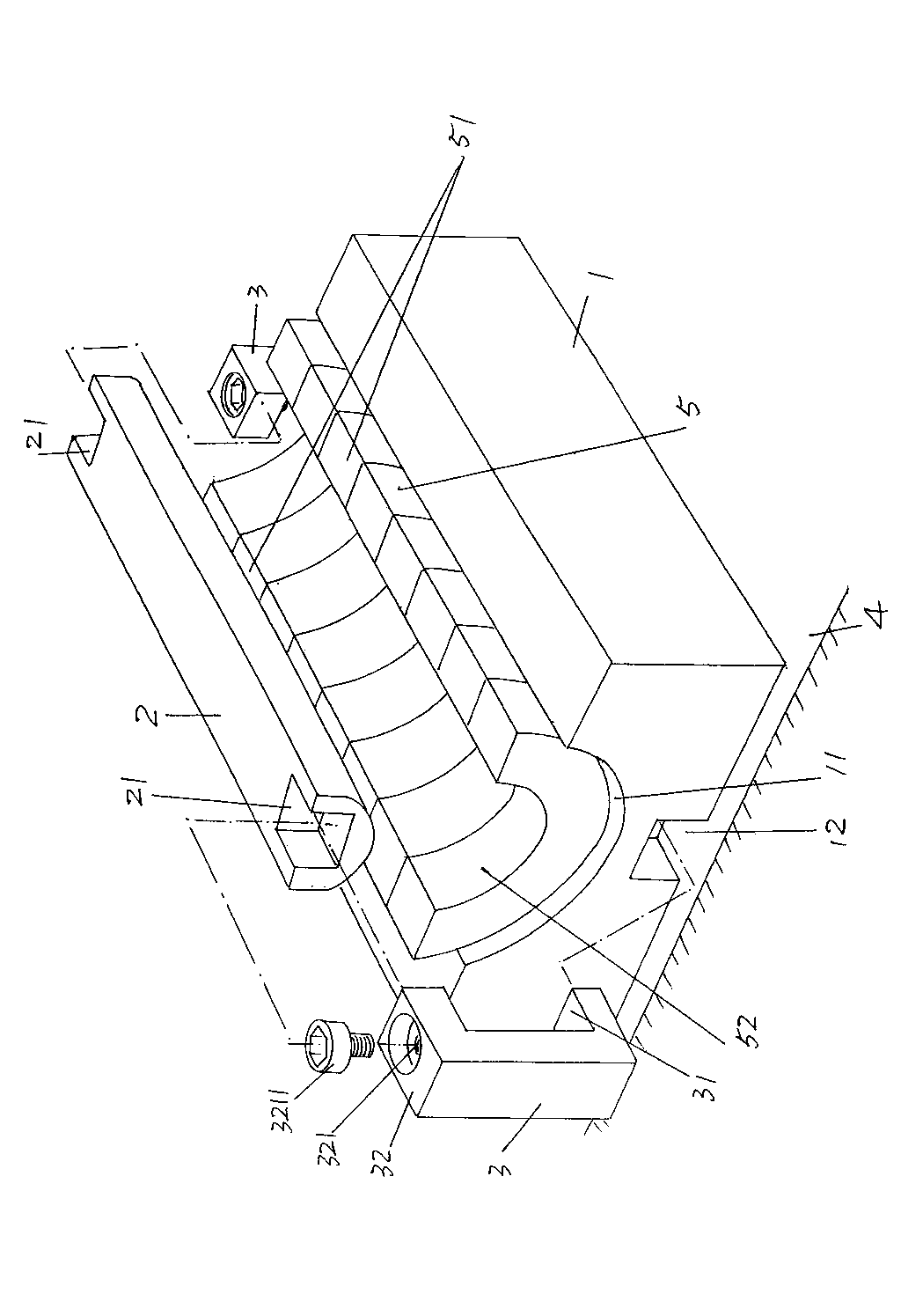

[0017] Please see figure 1 , gives a base 1 whose length does not need to be deliberately limited, in order to facilitate the understanding of the public in figure 1 In the center, the grinder table 4 of the grinder and the C-shaped ferrite core 5 used for grinding are shown. The surface of the base 1 facing upward in the use state, that is, the surface of the side facing the ferrite core 5, is formed from one end to the other end in the length direction (also called the long side direction) of the base 1, that is, A C-shaped cavity 11 from the left end of the illustrated position state to the right end, the depth of this C-shaped cavity 11 is smaller than the height of the ferrite core 5, so that the two ends of the ferrite core 5 protrude from the C-shaped cavity 11. Grinding the end face 51 of the ferrite core 5 with a grinder of a grinding machine. The side of the base 1 facing downwards in the state of use, that is, the two ends of the side facing the aforementione...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com