Buffering protection type oil gas suspension system and vehicle

An oil-air suspension and protection technology, which is applied to vehicle components, suspensions, elastic suspensions, etc., can solve the problems of oil-air suspension system damage, reduce vehicle height, and small structural size, and achieve easy oil circuit transformation and ensure safety and reliability, the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

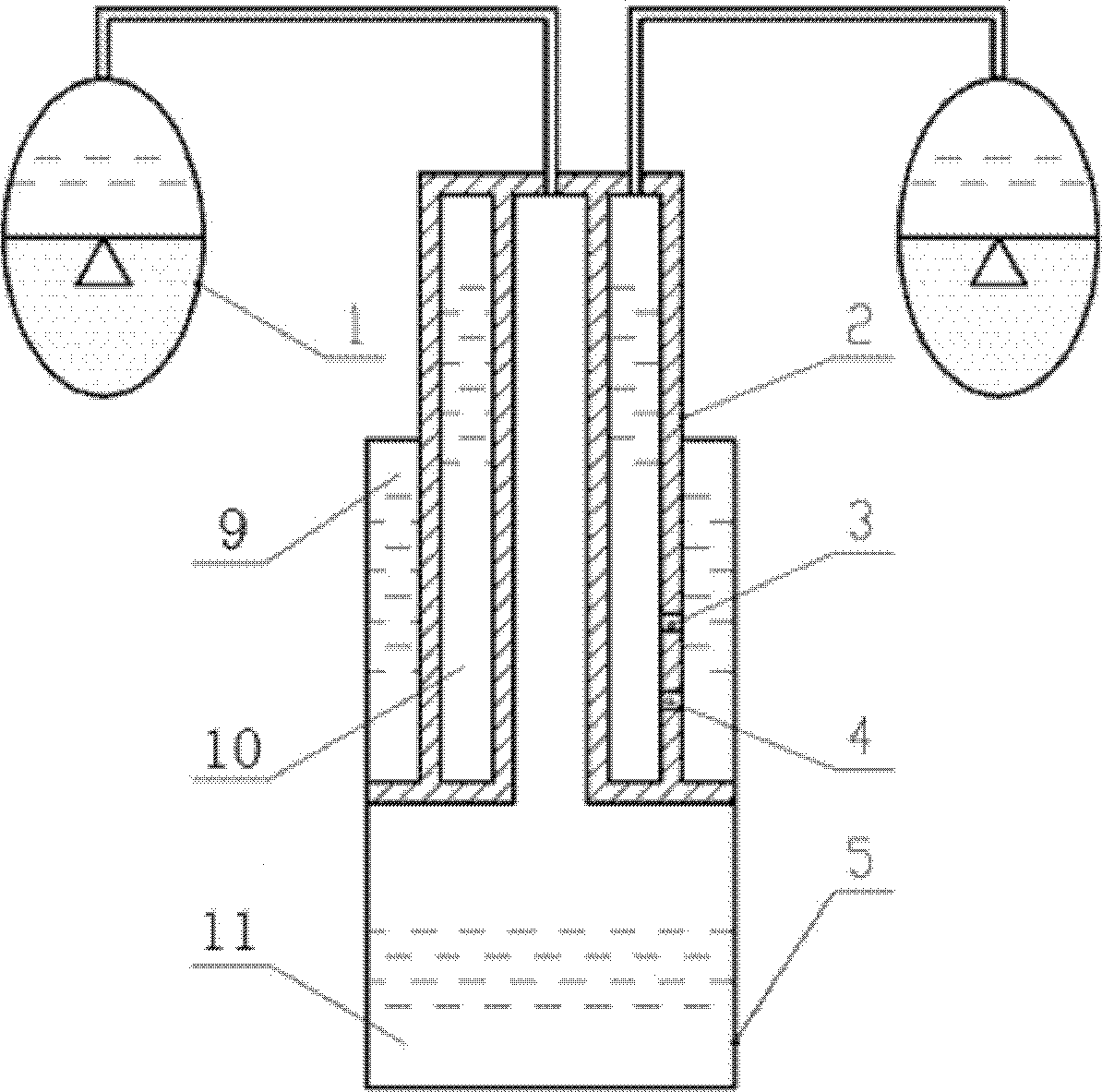

Method used

Image

Examples

Embodiment approach

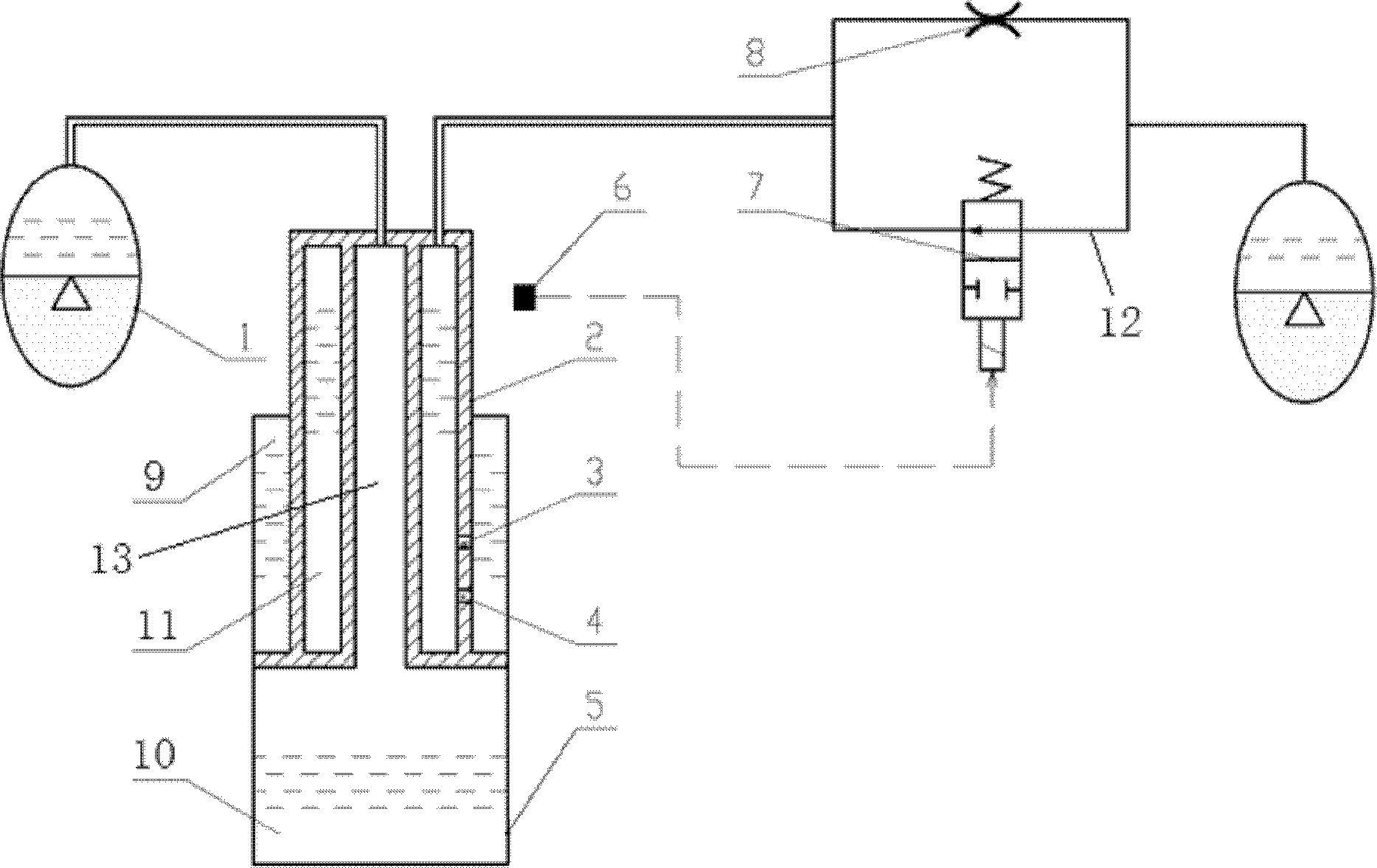

[0040] For example, specifically, the above-mentioned reversing valve adopts an electronically controlled reversing valve, and the buffer protection type oil-gas suspension system of the present invention further includes a travel switch 6. Preferably, the travel switch 6 is a proximity switch (ie a non-contact travel switch) The travel switch 6 is connected to the circuit of the reversing valve and is arranged at a predetermined position of the piston rod of the suspension cylinder, for example, on the rod head of the piston rod. In the case where the travel switch 6 adopts the proximity switch, the setting position of the proximity switch can be various, and is not limited to being installed on the piston rod. For example, it is installed on the cylinder or installed near the suspension cylinder through a bracket. It is enough to detect the position of the piston rod relative to the cylinder. In the case where the travel switch 6 of the present invention is the proximity swit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com