Hybrid powertrain system using selectable one-way clutches

A one-way clutch and hybrid power technology, which is applied to the layout of multiple different prime movers of hybrid vehicles, power plants, and general power plants, and can solve the problems of increasing the weight and power consumption of powertrain systems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

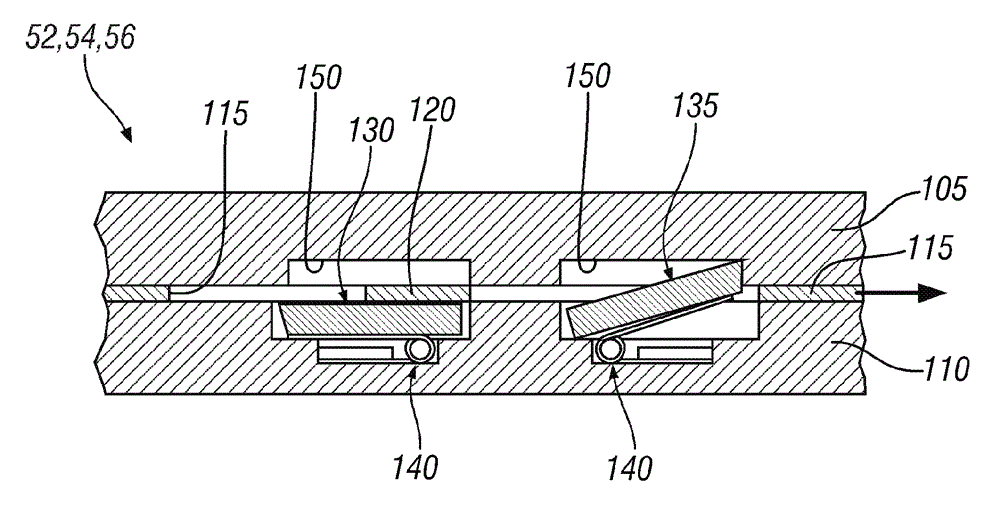

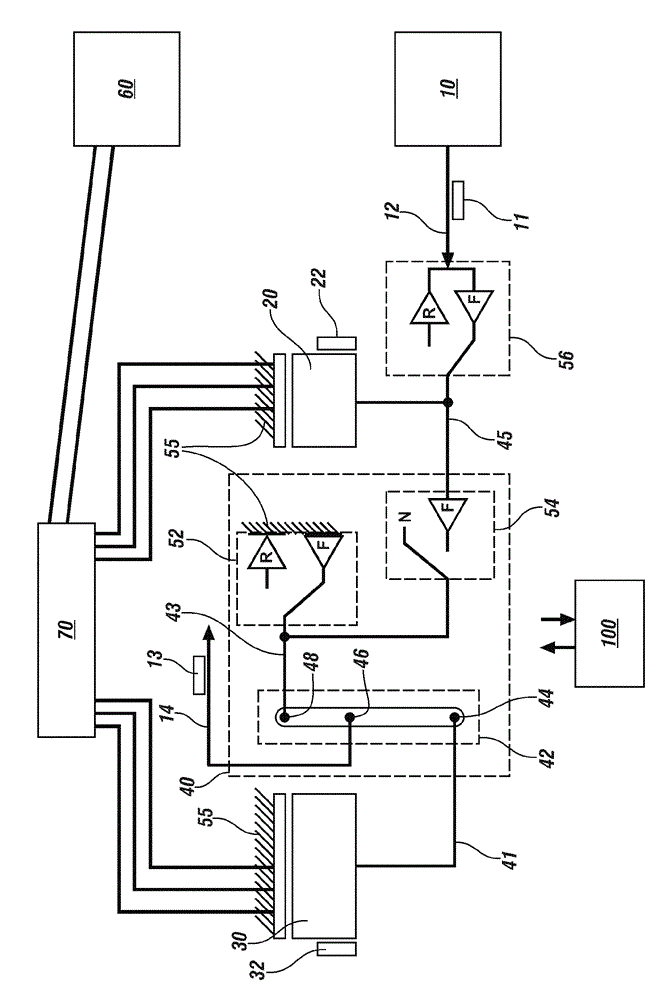

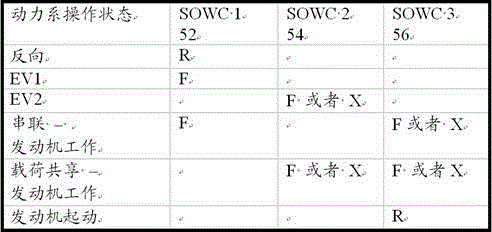

[0057] Referring now to the drawings, which are shown for the purpose of illustrating certain exemplary embodiments only and not for the purpose of limiting the invention, figure 1 A hybrid powertrain system including internal combustion engine 10 , transmission 40 , first and second torque machines 20 and 30 , respectively, is schematically illustrated, and a control module 100 is also schematically illustrated. Energy storage device 60 is electrically coupled to converter module 70, preferably via a high voltage DC bus. The inverter module 70 is electrically coupled to the first and second torque machines 20 , 30 , respectively, to convert and transmit electrical power for torque generation and electrical power generation.

[0058] Internal combustion engine 10 is mechanically coupled to transmission 40 via input member 12 and may comprise any suitable internal combustion engine. The first and second torque machines 20, 30 are machines that convert stored energy into torque...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com