General bridge designing method for turnover and storage of large bus axle

A design method and general-purpose bridge technology, applied in the direction of external frames, assembly vehicles, machine containers, etc., can solve the problems of vacant vehicle and bridge bridges, insufficient bridges, and non-universal use, etc., to reduce the number of bridges, save material consumption, The effect of reducing the occupied space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

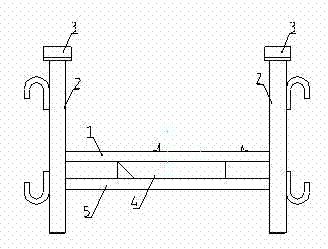

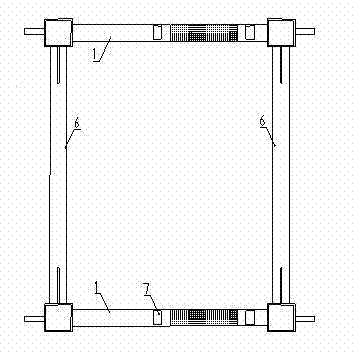

[0016] Such as Figure 1-3 As shown, the general bridge design method for the turnover and storage of large bus axles is composed of upper beam 1, sleeve column 3, middle beam 4, lower beam 5, rear axle limit 7, and front axle limit 8. There are four columns 2, and the four columns 2 are welded into a rectangle by the beam and the longitudinal beam 6, and the upper ends of the four columns 2 are respectively covered with sleeve columns 3; the beams are divided into upper beams 1 and lower beams. Beam 5, between the upper beam 1 and the lower beam 5 is welded with a middle beam 4 with a length of 390±50 mm and a height of 60 mm. The distance between the middle beam 4 and the columns 2 on both sides is equal, and the upper beam 1 is welded with The rear bridge limit 7 is welded with the front bridge limit 8 on the longitudinal beam 6; the length of the upper beam 1 and the lower beam 5 is 740 ± 10mm, and the distance between the lower beam 5 and the bottom of the column 2 is 160...

Embodiment 2

[0018] A general-purpose bridge frame for the turnover and storage of large bus axles, which is welded by the upper beam 1, the sleeve column 3, the middle beam 4, the lower beam 5, the rear axle limiter 7, and the front axle limiter 8 components. There are four upright columns 2, and the four upright columns 2 are welded into a rectangle by the beam and the longitudinal beam 6, and the upper ends of the four upright columns 2 are respectively covered with sleeve columns 3; the beam is divided into an upper beam 1 and a lower beam 5. A middle beam 4 with a length of 390±50 mm and a height of 60 mm is welded between the beam 1 and the lower beam 5. The distance between the middle beam 4 and the columns 2 on both sides of it is equal, and the upper beam 1 is welded with a rear bridge limit 7 , the front bridge limiter 8 is welded on the longitudinal beam 6; the length of the upper beam 1 and the lower beam 5 is 740 ± 10 mm, and the distance between the lower beam 5 and the bottom...

Embodiment 3

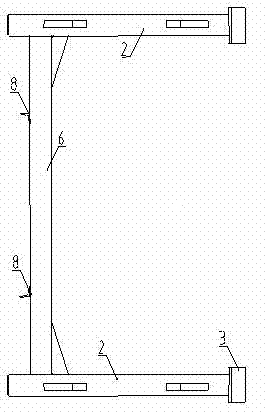

[0020] The present invention is used as follows: Figure 4 As shown, when the bridge structure is placed in the forward direction, a passenger car rear axle 9 is placed on the two beams 1, and the adjacent two floors are placed; or if Figure 5 As shown, when the bridge frame structure is reversed, two longitudinal girders 6 can take the situation of placing two passenger car front axles 10 . The figure shows that the axle does not interfere with the adjacent structure, and the distance is moderate.

[0021] The components in the above embodiments are not limited to the model being implemented, and may also be other models; the material is not limited to square steel, but may also be other steel materials.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com