Polymerization method of anti-impact propylene copolymer having high melt flowability

A propylene copolymer and fluidity technology, which is applied in the field of producing impact propylene copolymer with high melt fluidity, can solve the problems of conflicting requirements of different catalysts, no consideration, and limitation of molecular structure control of impact copolymer polypropylene products.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] The main catalyst (titanium-containing solid catalyst active component) is prepared by the method described in Example 1 of Chinese Patent CN93102795, its Ti content: 2.4wt%, Mg content 18.0wt%, di-n-butyl phthalate content: 13wt %.

[0043] The polymerization reaction was carried out on a polypropylene pilot plant.

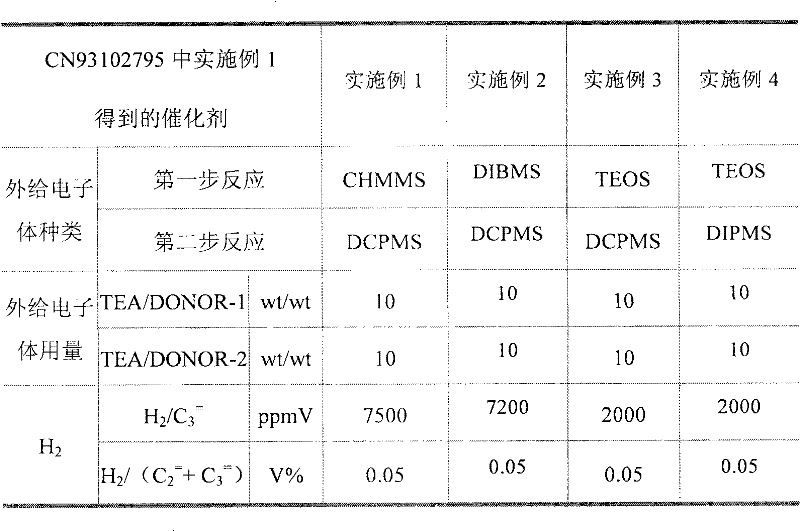

[0044] Pre-polymerization: After the main catalyst, co-catalyst (triethylaluminum), and the first external electron donor (methylcyclohexyldimethoxysilane) are pre-contacted at 10°C for 20 minutes, they are continuously added to the pre-polymerization reactor for pre-polymerization. Polymerization reactor, the flow of triethylaluminum (TEA) entering the prepolymerization reactor is 6.33g / hr, the flow of methylcyclohexyldimethoxysilane (CHMMS) is 0.63g / hr, and the flow of main catalyst is 0.01g / hr hr. The pre-polymerization is carried out in the environment of the propylene liquid phase body, the temperature is 15°C, and the residence time is about 4 minu...

Embodiment 2

[0053] The catalyst used in embodiment 2, pre-complexation and polymerization process conditions are identical with embodiment 1. The difference from Example 1 is that the first external electron donor in Example 2 is diisobutyldimethoxysilane (DIBMS). The specific process conditions are shown in Table 1.

Embodiment 3

[0055] The catalyst used in embodiment 3, pre-complexation and polymerization process conditions are identical with embodiment 1. The difference from Example 1 is that the first external electron donor in Example 3 is tetraethoxysilane (TEOS). The specific process conditions are shown in Table 1.

PUM

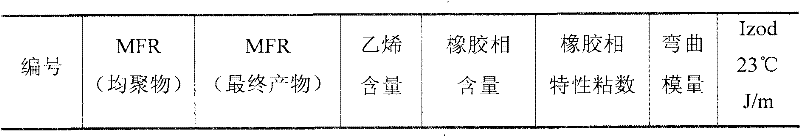

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap