Antiflaming polycarbonate composition compounded by phosphazene compound

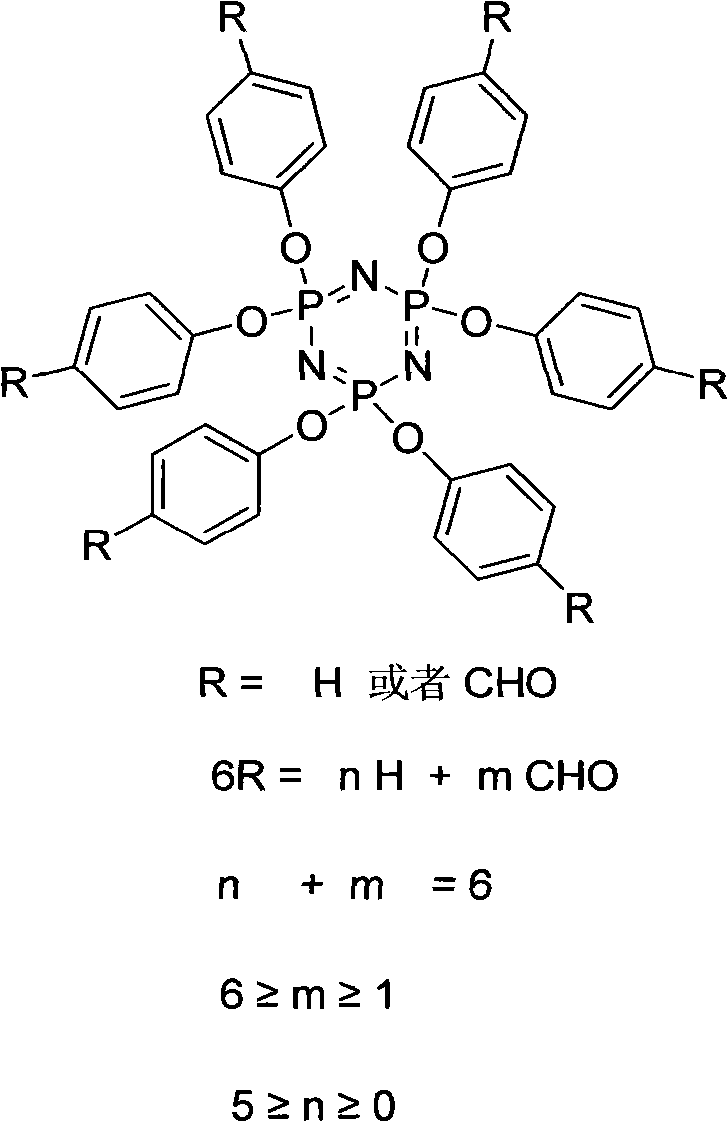

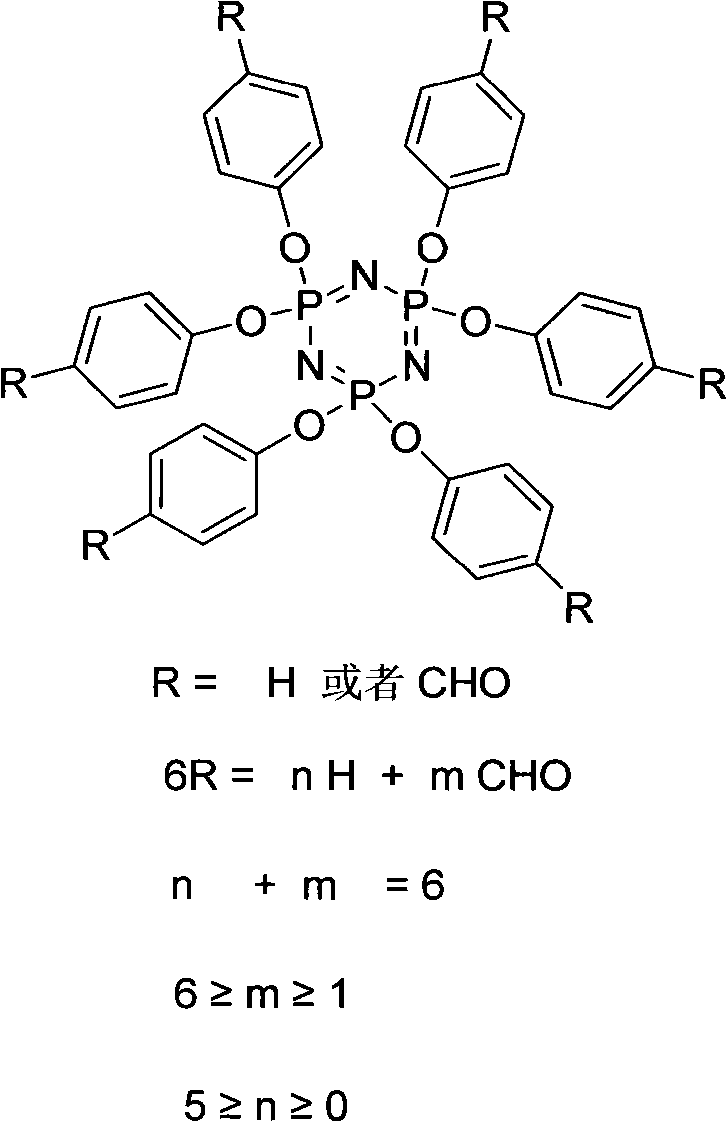

A technology of flame-retardant polycarbonate and phosphazene compounds, which is applied in the field of polycarbonate compositions, can solve problems such as failure to meet flame-retardant standards, and achieve the effects of easy flame extinguishing, high-efficiency flame-retardant systems, and excellent flame-retardant properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

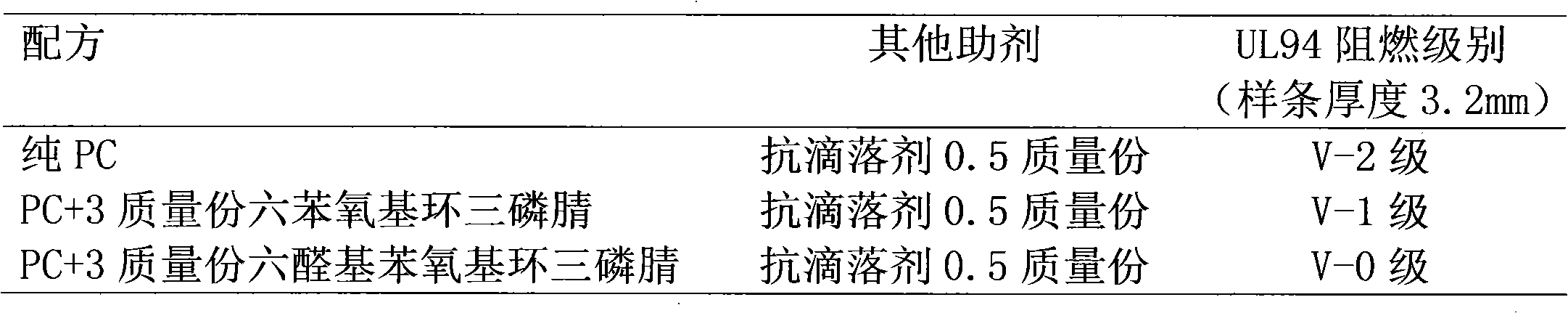

[0019] Example 1 Weigh 100 parts by mass of PC, add 3 parts by mass of hexa-(formylphenoxy)-cyclotriphosphazene, add 0.2 parts by mass of 1010 antioxidant, add 0.2 parts by mass of 168 antioxidant, add polytetrafluoroethylene 0.5 parts by mass of vinyl fluoride anti-dripping agent. After physically blending the above materials, melt blending by twin-screw extrusion to form a flame-retardant PC composition with uniform dispersion of components. The composition reaches a 3.2mm thick spline UL94V -Class 0 flame retardant level.

Embodiment 2

[0020] Example 2 Weigh 100 parts by mass of PC, add 10 parts by mass of ABS resin, add 4 parts by mass of hexa-(formylphenoxy)-cyclotriphosphazene, add 0.2 parts by mass of 1010 antioxidant, add 168 parts by mass of antioxidant 0.2 parts by mass, add 0.5 parts by mass of polytetrafluoroethylene anti-dripping agent, after physical blending of the above materials, melt blending by twin-screw extrusion to form a uniformly dispersed flame-retardant PC composition of each component, the composition reaches 3.2mm thick spline UL94V-0 flame retardant level.

Embodiment 3

[0021] Example 3 Weigh 100 parts by mass of PC, add 20 parts by mass of ABS resin, add 7 parts by mass of hexa-(formylphenoxy)-cyclotriphosphazene, add 0.2 parts by mass of 1010 antioxidant, add 168 parts by mass of antioxidant 0.2 parts by mass, add 0.5 parts by mass of polytetrafluoroethylene anti-dripping agent, after physical blending of the above materials, melt blending by twin-screw extrusion to form a uniformly dispersed flame-retardant PC composition of each component, the composition reaches 3.2mm thick spline UL94V-0 flame retardant level.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com