Meter assembly, sheath fluid impedance meter and flow cytometer

A technology of counters and components, applied in the field of sheath flow impedance counting devices, can solve the problems of loss of control of liquid level, change of liquid level, no actual connection between the rear sheath and the front sheath, etc., and achieves the effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described in detail below through specific embodiments in conjunction with the accompanying drawings.

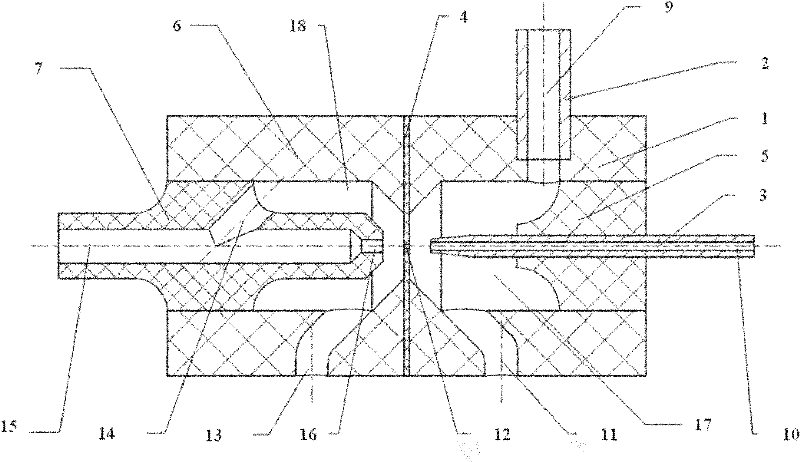

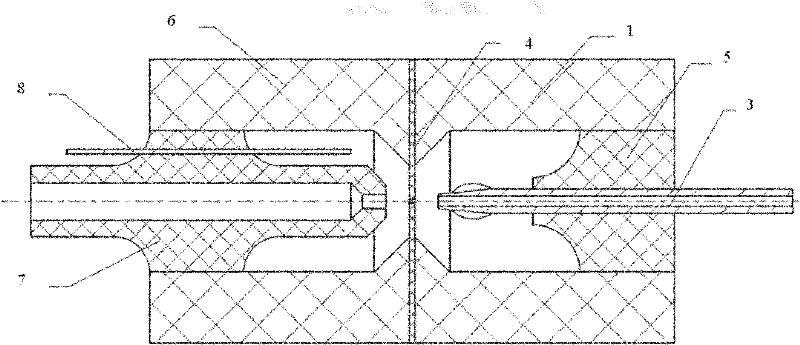

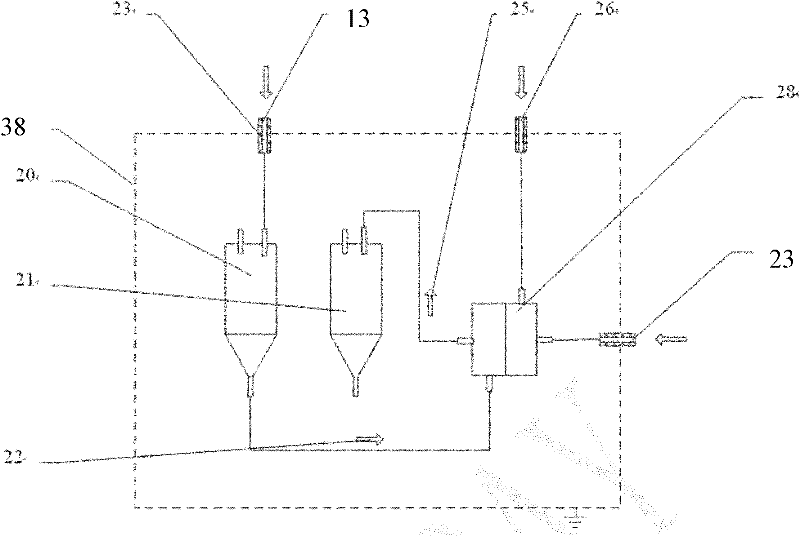

[0035] Such as figure 1 , Figure 4 and Figure 5As shown, the sheath flow impedance counting device in this embodiment includes a counter assembly, a first container 33 and a second container 36 . The counter assembly includes a counter 28 , a rear sheath isolation chamber 20 and a waste fluid isolation chamber 21 . The counter 28 has a forebay 17 , a forebay cleaning inlet 11 , a front sheath inlet 9 and a sample solution inlet 10 , and the forebay cleaning inlet 11 , the front sheath inlet 9 and the sample solution inlet 10 are all in communication with the forebay 17 . The counter also has a rear pool 18 , a rear sheath inlet 13 and a waste liquid outlet 15 , and both the rear sheath inlet 13 and the waste liquid outlet 15 communicate with the rear pool 18 . A partition 4 is provided between the front pool 17 and the rear ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com