Three-layer device for tank exit, liquid brushing and storing and tank entry of manganese or zinc electrolytic cathode plate

A technology of electrolytic zinc and cathode plate, which is applied in the field of electrolytic manganese or electrolytic zinc cathode plate exiting the tank, entering the tank, three-layer device, brushing liquid and storing liquid, which can solve the problems of unfavorable clean production, dripping on the ground, and polluting the working environment And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

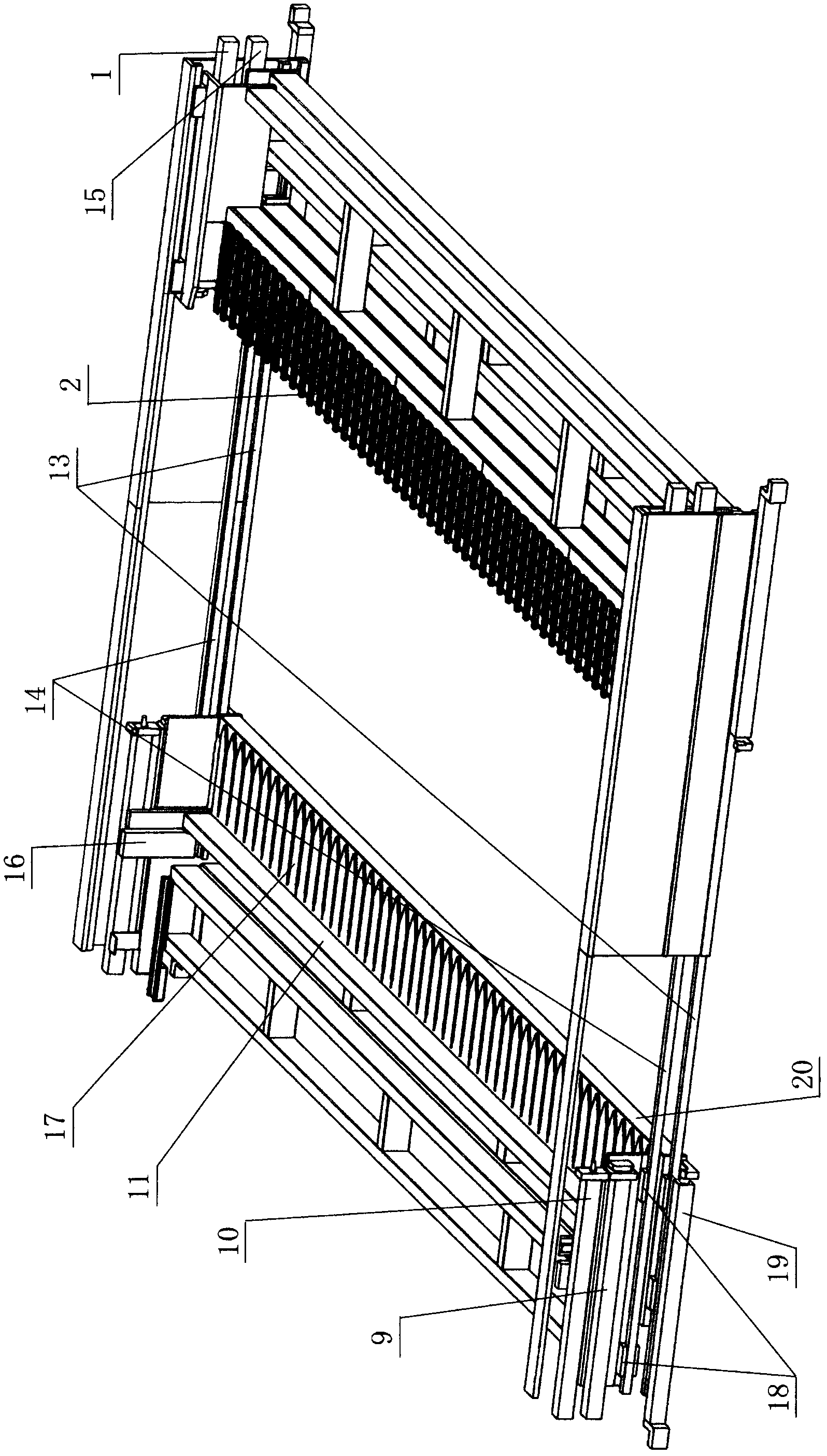

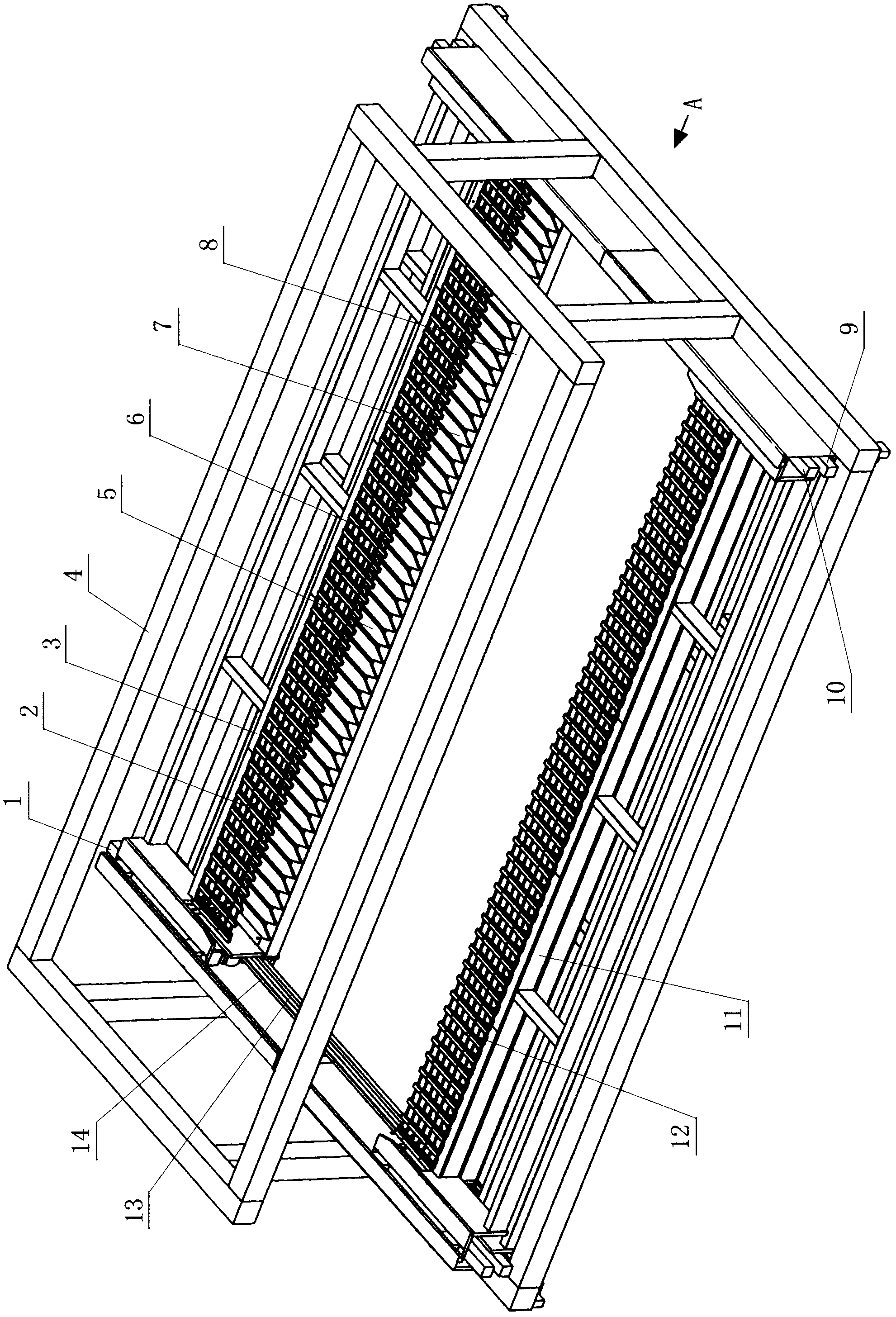

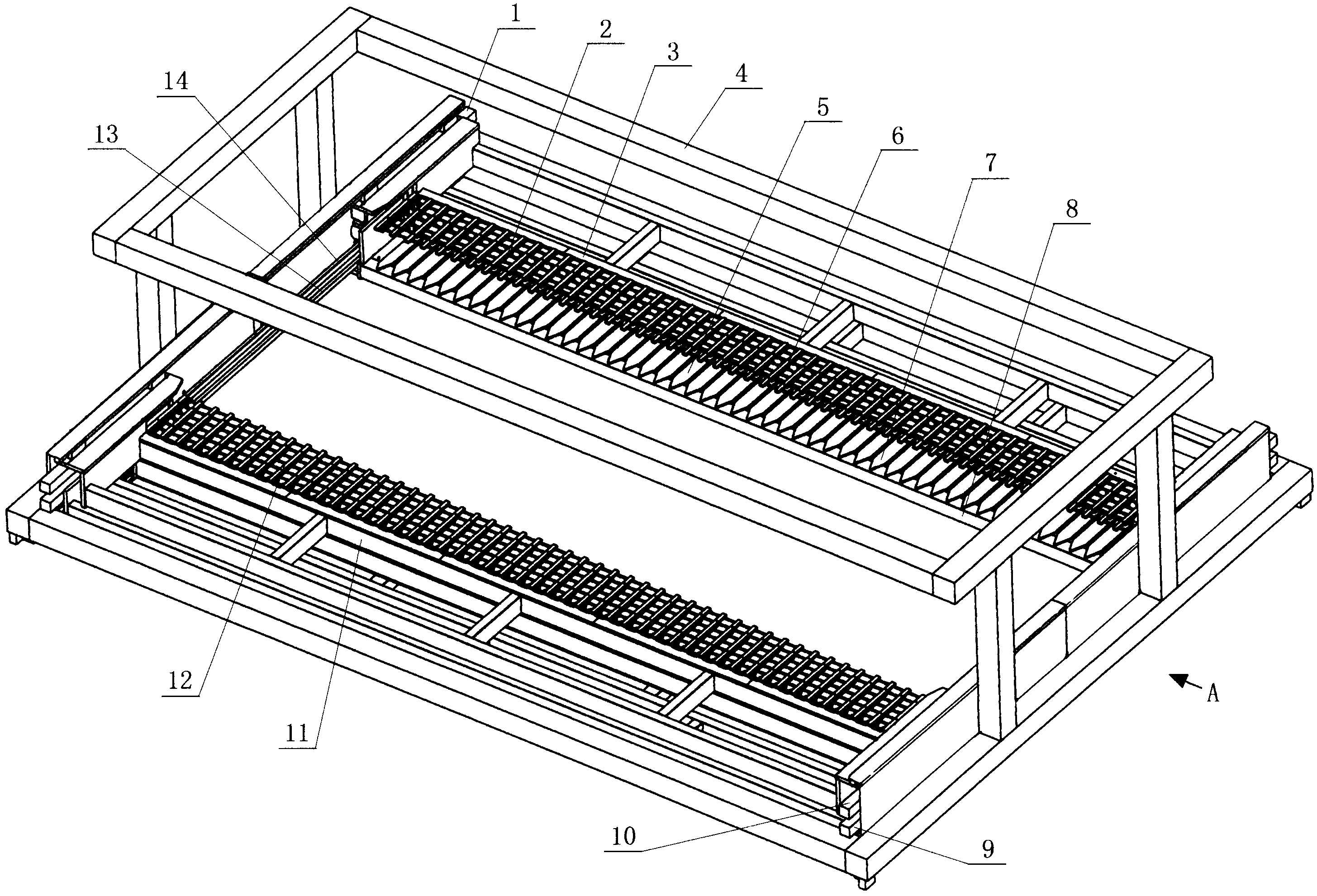

[0010] figure 1 with figure 2 Among them, a three-layer device for electrolytic manganese or electrolytic zinc cathode plate exiting the tank, brushing liquid and storing liquid, and entering the tank, including a frame 4, a liquid brushing device 6, a positioning device 7, and a liquid storing device 8. The brush liquid device 6 includes a left brush liquid actuator 10 , a right brush liquid actuator 1 , a left hair brush 12 , and a right hair brush 2 . The left brush liquid actuator 10 and the right brush liquid actuator 1 are arranged on the inner upper parts of the left side and the right side of the frame 4 respectively. The left hair brush 12 is connected with the piston rod of the left brush liquid actuator 10, and the right hair brush 2 is connected with the piston rod of the right brush liquid actuator 1. The positioning device 7 includes a left support 11, a right support 3, a left positioning fork 17, a right positioning fork 5, a left actuator 9, a right actuato...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com