Warp-knitted fabric and production method thereof

A technology of warp knitted fabric and production method, which is applied in the direction of warp knitting, knitting, textiles and papermaking, and can solve problems such as snagging, lowering product grades, degreasing, high temperature setting, dyeing and post-processing difficulties, etc. Achieve broad market prospects, improve grades, and enhance the effect of level dyeing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] Embodiment 1: (cloth number: RC3079S)

[0055] 1. Basic parameters:

[0056] Non-elastic yarn: nylon (10 denier, 12 silk, round dark silk);

[0057] Elastic Yarn: Spandex (40 denier, bright silk)

[0058] Non-elastic yarn composition ratio: 61% (nylon)

[0059] Elastic yarn composition ratio: 39% (spandex)

[0060] Finished cloth weight: 142 g / m2

[0061] Warp density of finished fabric: 165 columns / inch

[0062] Finished fabric weft density: 81 lines / inch

[0063] 2. Basic weaving parameters

[0064] Machine type: 40-needle two-bar high-speed tricot machine (HKS 2-3E)

[0065] The total yarn number of the first bar: 5010,

[0066] The total threading number of the second bar: 4992 pieces,

[0067] First bar let-off: 1900mm / lack,

[0068] Let-off of the second bar: 596mm / lack (stretch rate of warp beam spandex: 80%),

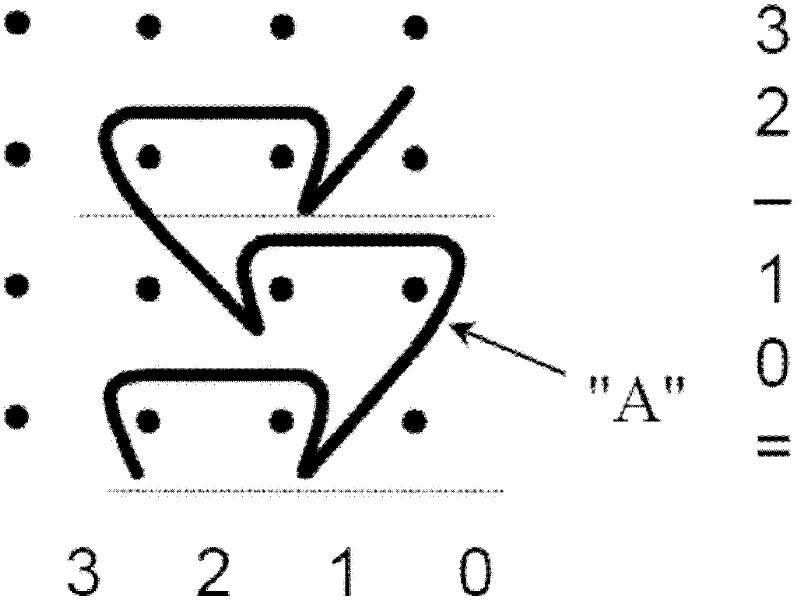

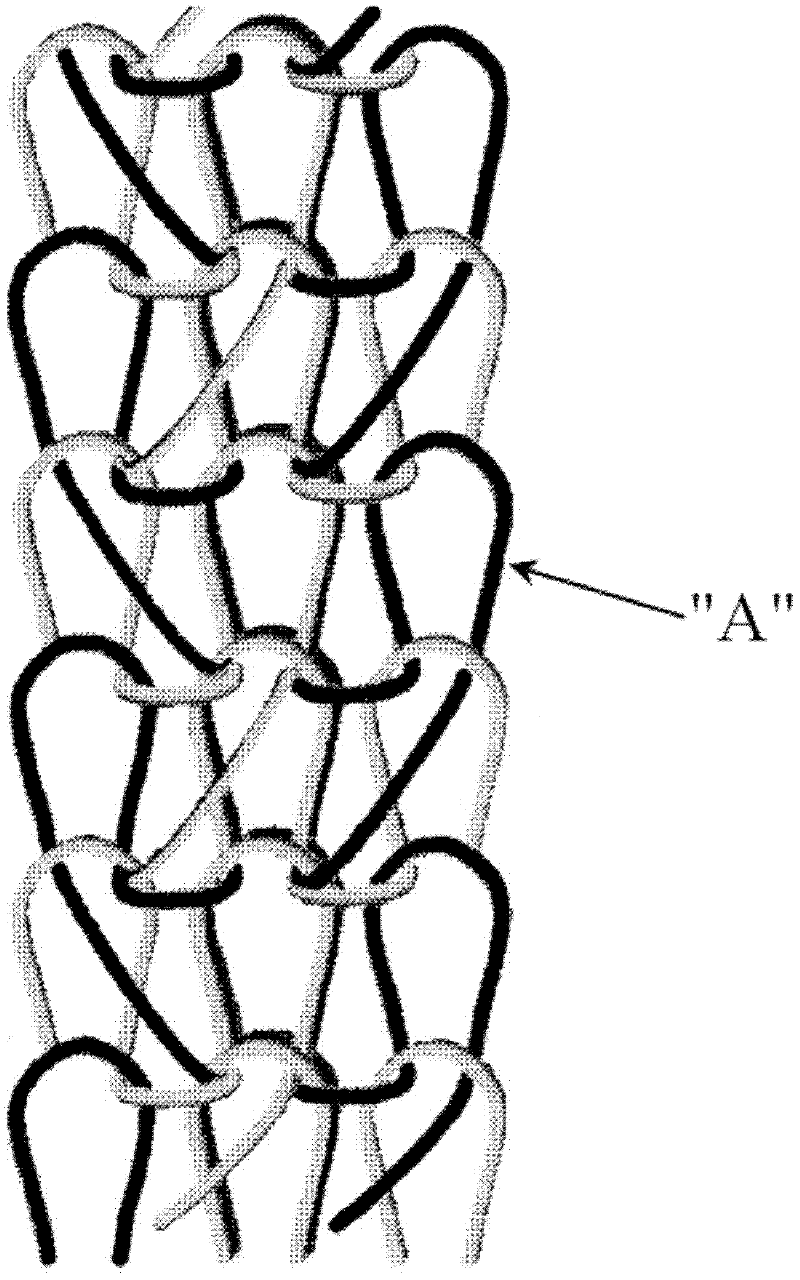

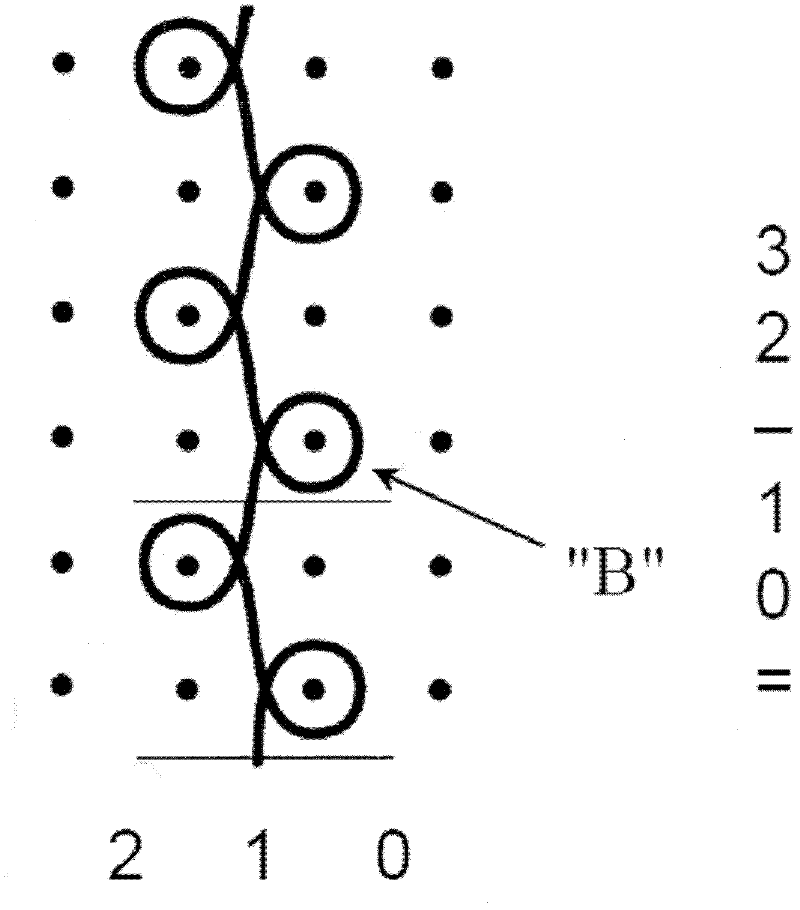

[0069] like figure 1 , figure 2 , image 3 and Figure 4 As shown, non-elastic yarn: Nylon is woven with 1×2 open heavy warp and plain we...

Embodiment 2

[0080] Embodiment 2: (cloth number: RC3293S)

[0081] 1. Basic parameters:

[0082] Non-elastic yarn: nylon (20 denier, 17 silk, round dark silk)

[0083] Elastic Yarn: Spandex (80 denier, bright silk)

[0084] Non-elastic yarn composition ratio: 62% (nylon)

[0085] Elastic yarn composition ratio: 38% (spandex)

[0086] Finished cloth weight: 189 g / m2

[0087] Warp density of finished fabric: 124 columns / inch

[0088] Finished fabric weft density: 62 lines / inch

[0089] 2. Basic weaving parameters:

[0090] Machine type: 32-needle two-bar high-speed tricot machine (HKS 2-3E)

[0091] The total yarn number of the first bar: 4032,

[0092] The total yarn number of the second bar: 4020,

[0093] First bar let-off: 2160mm / lack,

[0094] Let-off of the second bar: 600 mm / lack (stretch rate of warp beam spandex: 80%),

[0095] like figure 1 , figure 2 , image 3 and Figure 4 As shown, non-elastic yarn: Nylon is woven with 1×2 open heavy warp and plain weave structu...

Embodiment 3

[0106] Embodiment 3: cloth number: (RC3283SA)

[0107] 1. Basic parameters:

[0108] Non-elastic yarn: Nylon (20 denier, 34 silk, round bright silk)

[0109] Elastic Yarn: Spandex (40 denier, bright silk)

[0110] Non-elastic yarn composition ratio: 77% (nylon)

[0111] Elastic yarn composition ratio: 23% (spandex)

[0112] Finished cloth weight: 156 g / m2

[0113] Warp density of finished fabric: 122 columns / inch

[0114] Finished fabric weft density: 65 lines / inch

[0115] 2. Basic weaving parameters:

[0116] Machine type: 32-needle two-bar high-speed tricot machine (HKS 2-3E)

[0117] The total yarn number of the first bar: 4032,

[0118] The total yarn number of the second bar: 4020,

[0119] First bar let-off: 2050mm / lack,

[0120] Let-off of the second bar: 550 mm / lack (stretch rate of warp beam spandex: 80%),

[0121] like figure 1 , figure 2 , image 3 and Figure 4 As shown, non-elastic yarn: Nylon is woven with 1×2 open heavy warp and plain weave stru...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com