Deciduous wood P-RC APMP (pre-conditioning refiner chemical pretreatment alkaline peroxide mechanical pulp) pulping process using magnesium alkali

A technology for hardwood and pulping, which is applied in the direction of pretreatment with alkaline compounds, chemical/chemical mechanical pulping, textiles and papermaking, etc. It is not combined with the adjustment of process parameters, etc., to achieve the effect of improved scaling, high bulk and opacity, and small decrease in whiteness and strength

Active Publication Date: 2012-07-04

TIANJIN UNIVERSITY OF SCIENCE AND TECHNOLOGY

View PDF1 Cites 14 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0011] 2) Documents in groups 1, 2 and 3 are related to the research work on replacing sodium alkali with magnesium alkali for the high-yield pulping processes of TMP and BCTMP prevailing in North America, but not for the P-RC APMP process prevailing in my country. Research

Although the fourth group of documents is based on the P-RC APMP process to carry out the basic theoretical research on the high-yield pulping of magnesium alkali instead of sodium alkali, it does not explain the specific preparation pr

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| Tear index | aaaaa | aaaaa |

Login to View More

Abstract

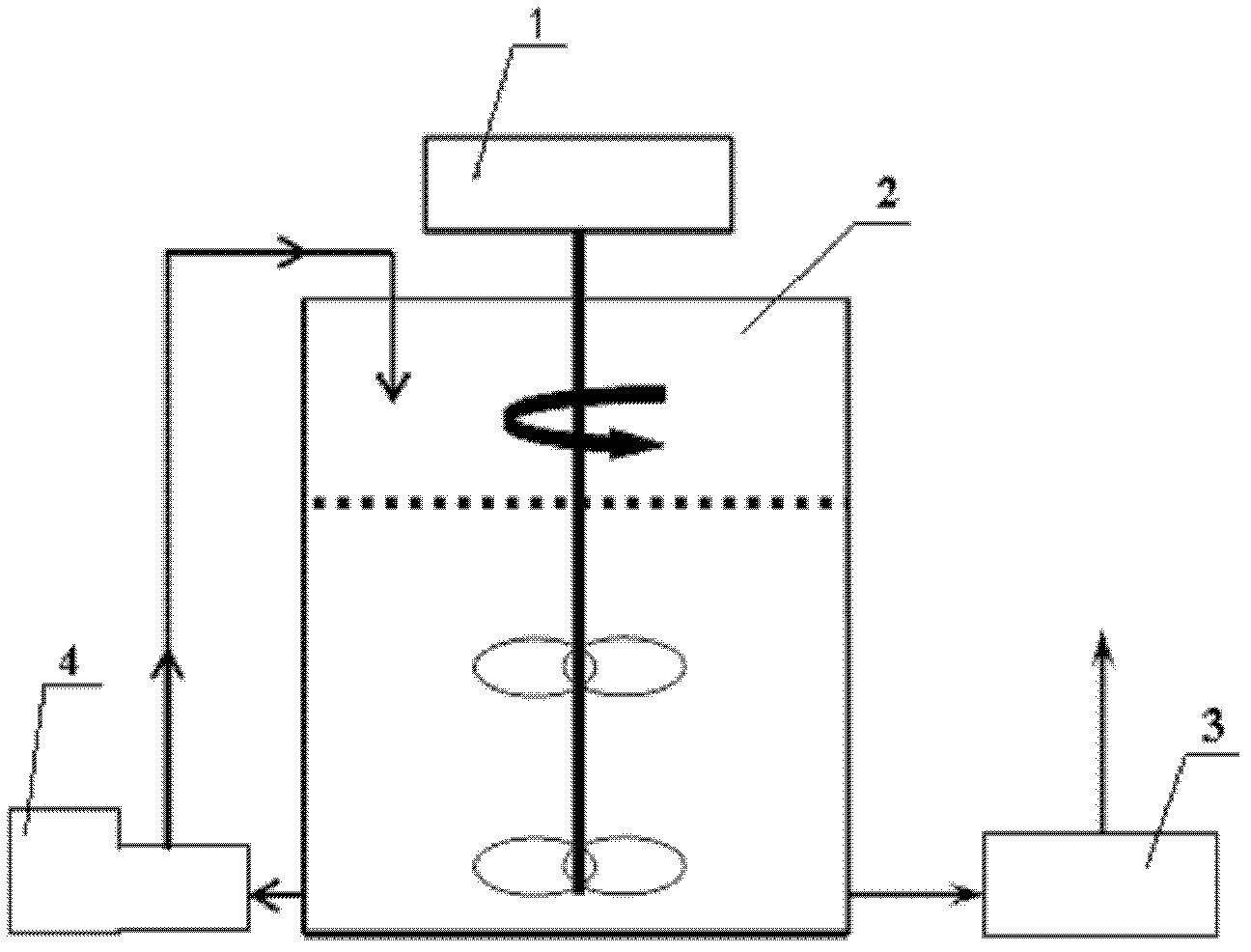

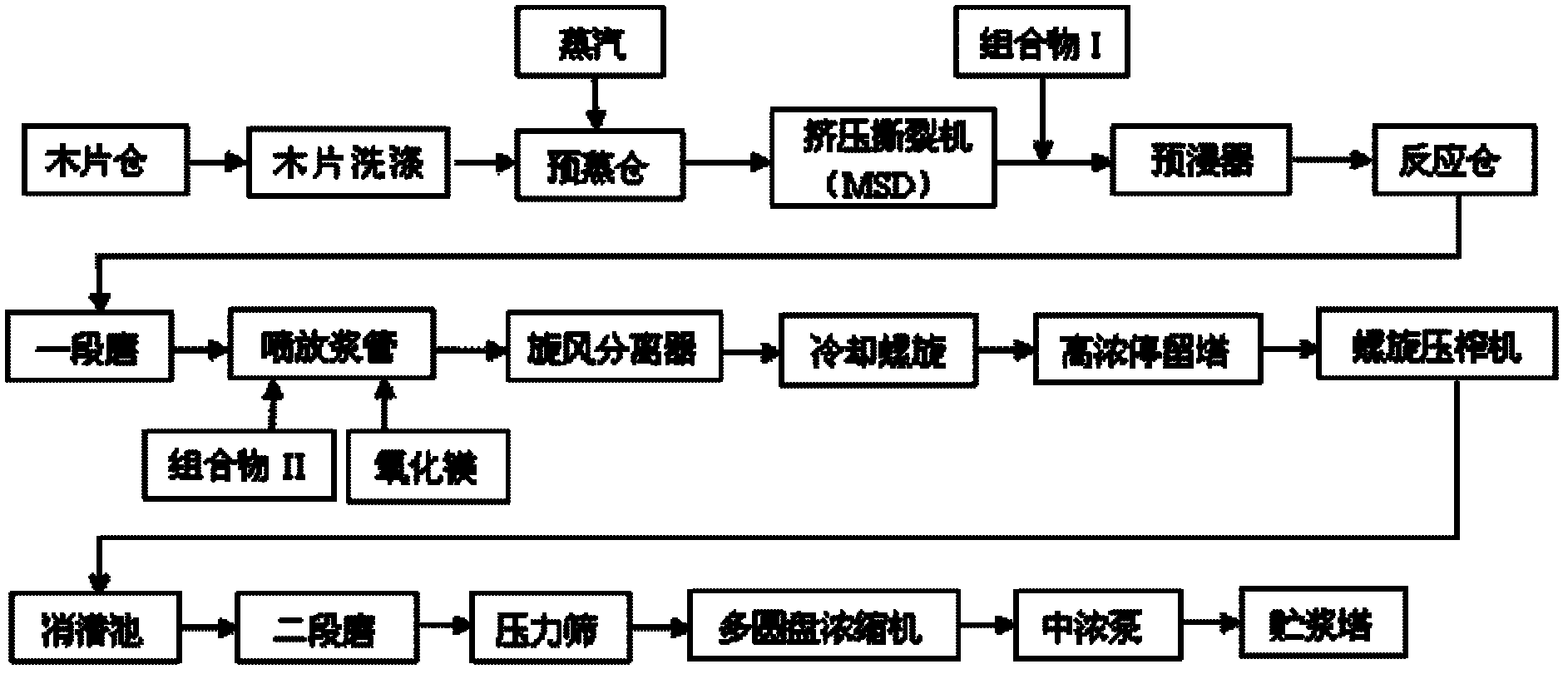

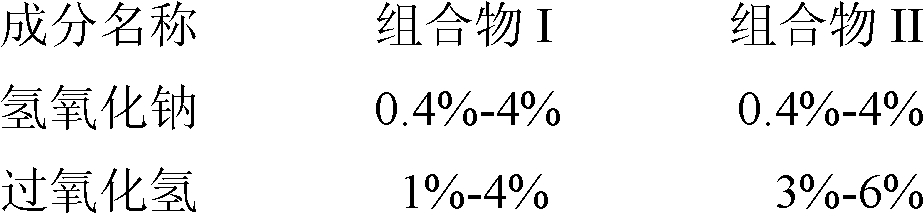

The invention relates to a deciduous wood P-RC APMP (pre-conditioning refiner chemical pretreatment alkaline peroxide mechanical pulp) pulping process using magnesium alkali, and provides a pulping process of the deciduous wood P-RC APMP; and the pulping process takes magnesium oxide as an alkali source and is economically feasible. According to the method, the magnesium oxide with higher purity (more than 85%) is adopted, a suspending liquid is prepared in a dissolution tank with mechanical circulation and stirring, and is added in a proper position (a slurry-spraying pipe) of a P-RC APMP pulping process pipeline, a suitable pH (potential of hydrogen) value environment is provided, and finally, fine-performance high yield pulp fibre is prepared.

Description

technical field [0001] The invention belongs to the field of pulping and papermaking, and relates to a P-RC APMP pulping method using magnesium alkali. Background technique [0002] The shortage of plant fiber raw materials and environmental pollution have always been the main obstacles restricting the sustainable and healthy development of my country's pulp and paper industry. In recent years, the high-yield pulping process has gradually attracted attention due to its advantages such as lower fiber cost and environmental pollution load, and has developed very rapidly. High-yield pulp usually includes: Stone Ground Wood (SGW), Refiner Mechanical Pulp (RMP), Thermo Mechanical Pulp (Thermo Mechanical Pulp, TMP), bleached chemical thermomechanical pulp (Bleached Chemi-Thermo Mechanical Pulp, BCTMP), Alkaline Peroxide Mechanical Pulp (Alkaline Peroxide Mechanical Pulp, APMP) and Alkaline Peroxide Mechanical Pulp (Pre-conditioning Refiner Chemical Pretreatment) Alkaline Peroxid...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): D21H11/02D21B1/12D21C1/06

Inventor 侯庆喜张红杰胡惠仁倪永浩

Owner TIANJIN UNIVERSITY OF SCIENCE AND TECHNOLOGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com