Variable-cross-section structure for deep sewer of roadbed and construction method thereof

A variable cross-section and seepage ditch technology, which is applied to roads, roads, and road bottom layers, can solve problems such as slow construction progress, high construction costs, and inability to excavate seepage trenches to improve stability, construction efficiency, and construction safety. , Reduce the effect of local flow mud or flow soil collapse damage phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

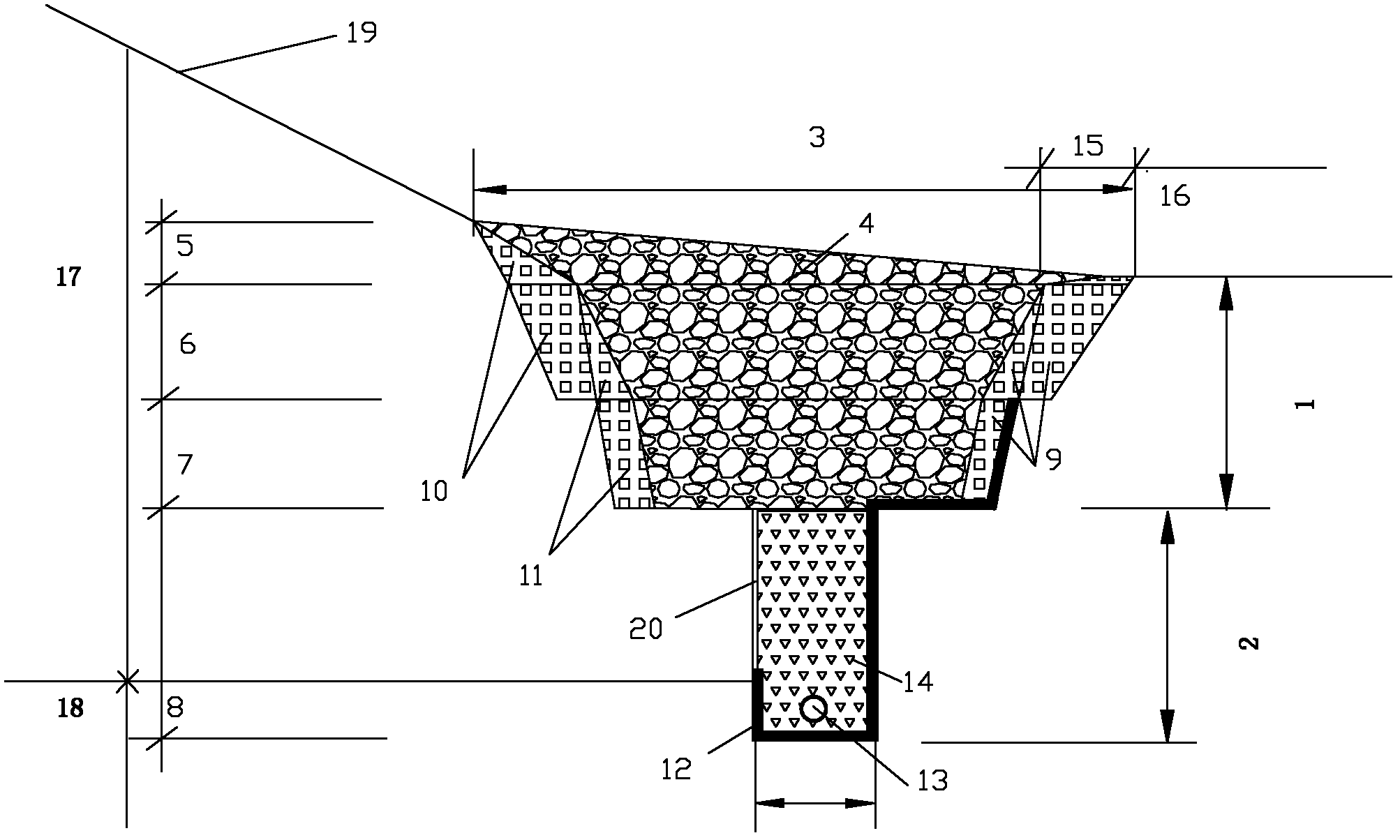

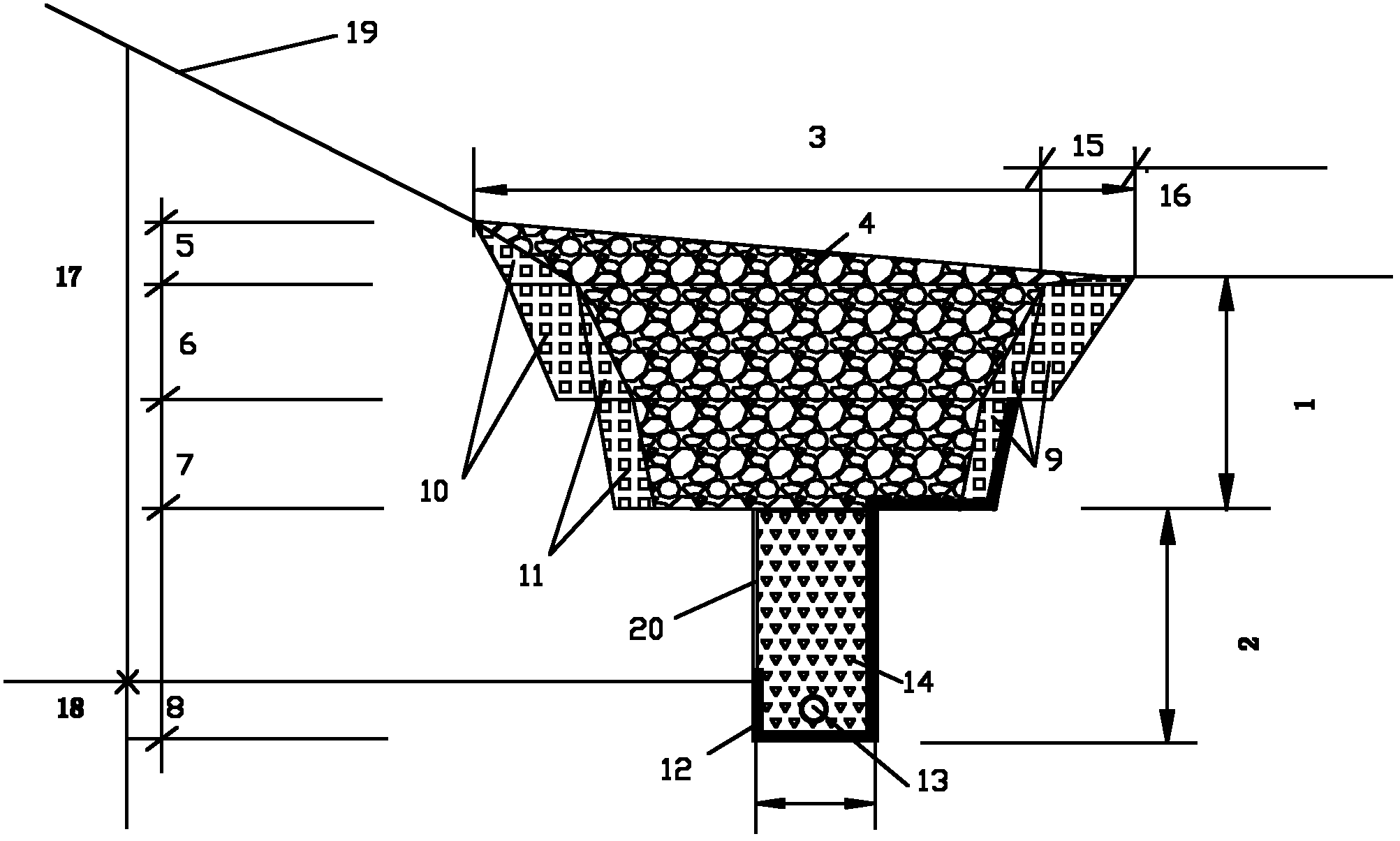

[0014] see figure 1 , the variable cross-section structure of the subgrade deep seepage ditch is composed of two parts: the lower small-section excavation area 2 and the upper large-section excavation area 1 above the lower small-section excavation area 2, and the upper large-section excavation area 1 consists of the first excavation area The excavation layer 6, the second excavation layer 7 and the rolling initial leveling layer 5 are composed, the rolling initial leveling layer 5 is above the first excavation layer 6, the first excavation layer 6 is above the second excavation layer 7, The first excavation layer 6, the second excavation layer 7, and the rolling initial leveling layer 5 are all composed of backfill flakes 9 distributed on the sides and backfill gravel soil 4 in the middle; the first excavation layer 6 is excavated in a single ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com