Through prestress steel truss and concrete combined continuous steel structure bridge and construction method thereof

A technology of prestressed steel and prestressed steel strands, which is applied in the field of down-loaded prestressed steel truss-concrete composite continuous rigid frame bridges and construction fields, and can solve the problem of steel truss-concrete composite continuous rigid frame bridges with extremely large spans. Construction, bridge building height restrictions and other issues, to achieve reliable long-term structural performance, reduce self-weight, and avoid long-term excessive deflection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

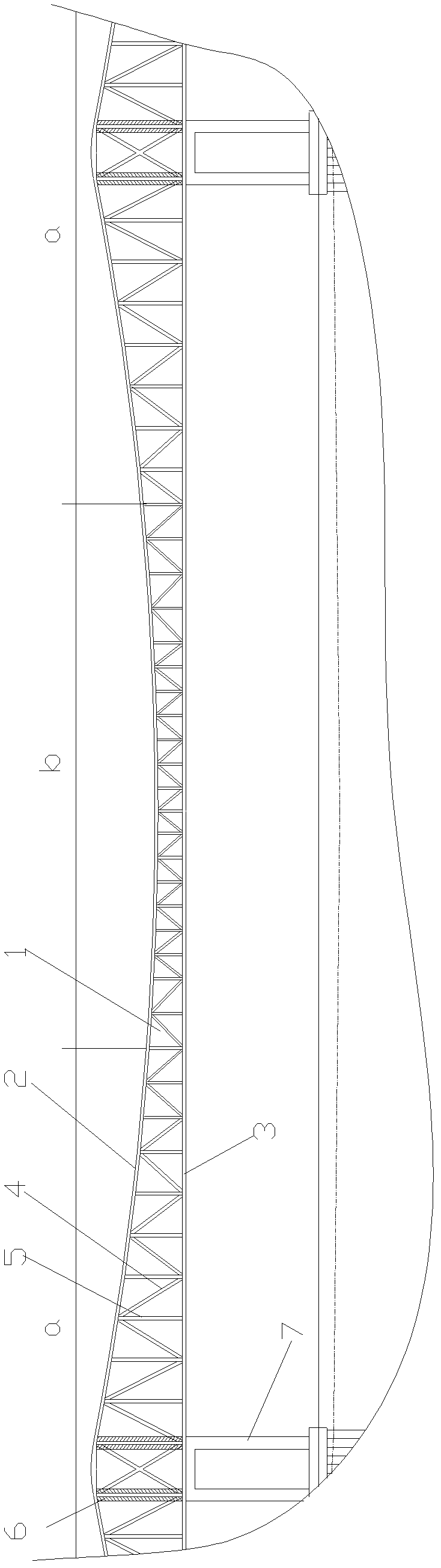

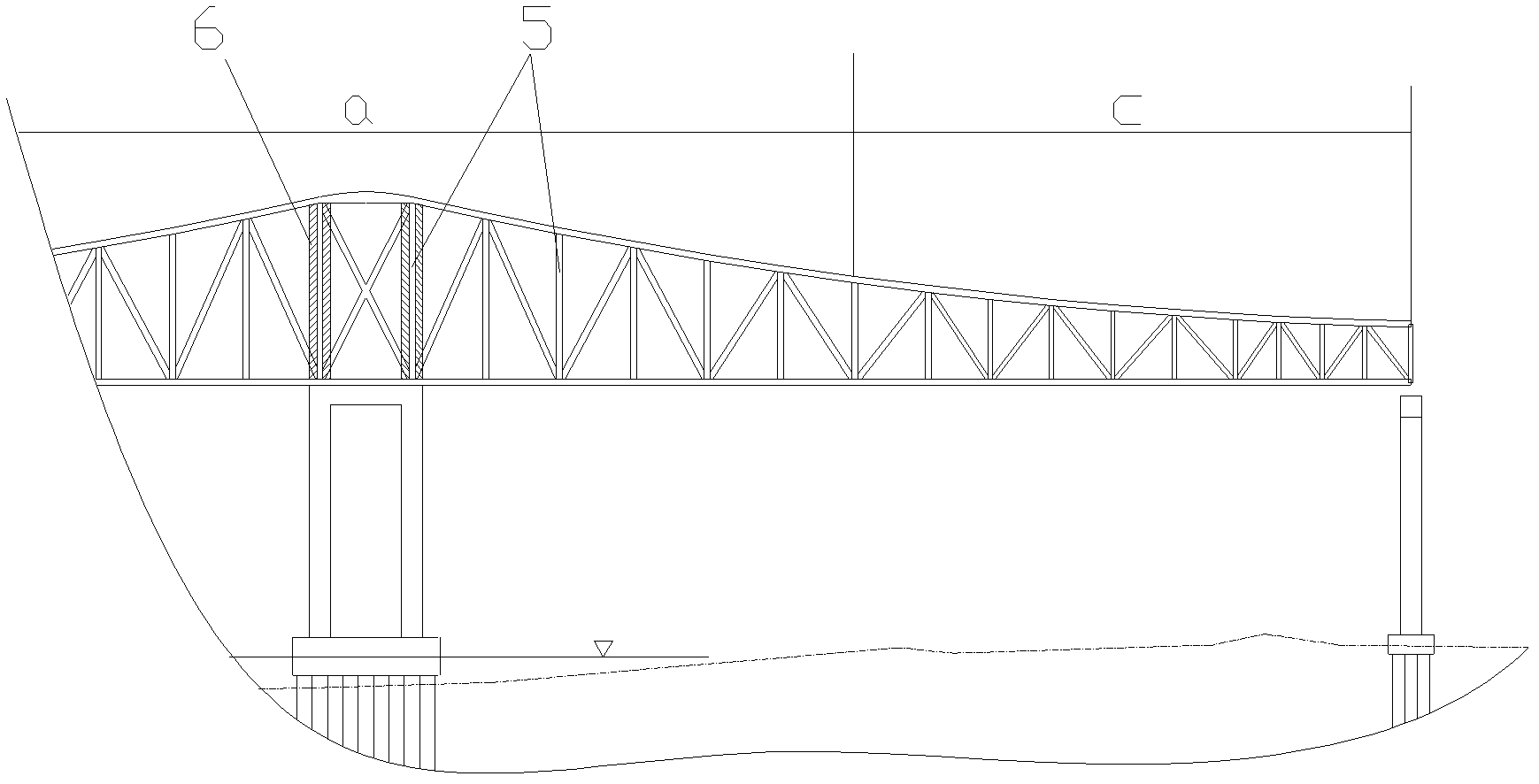

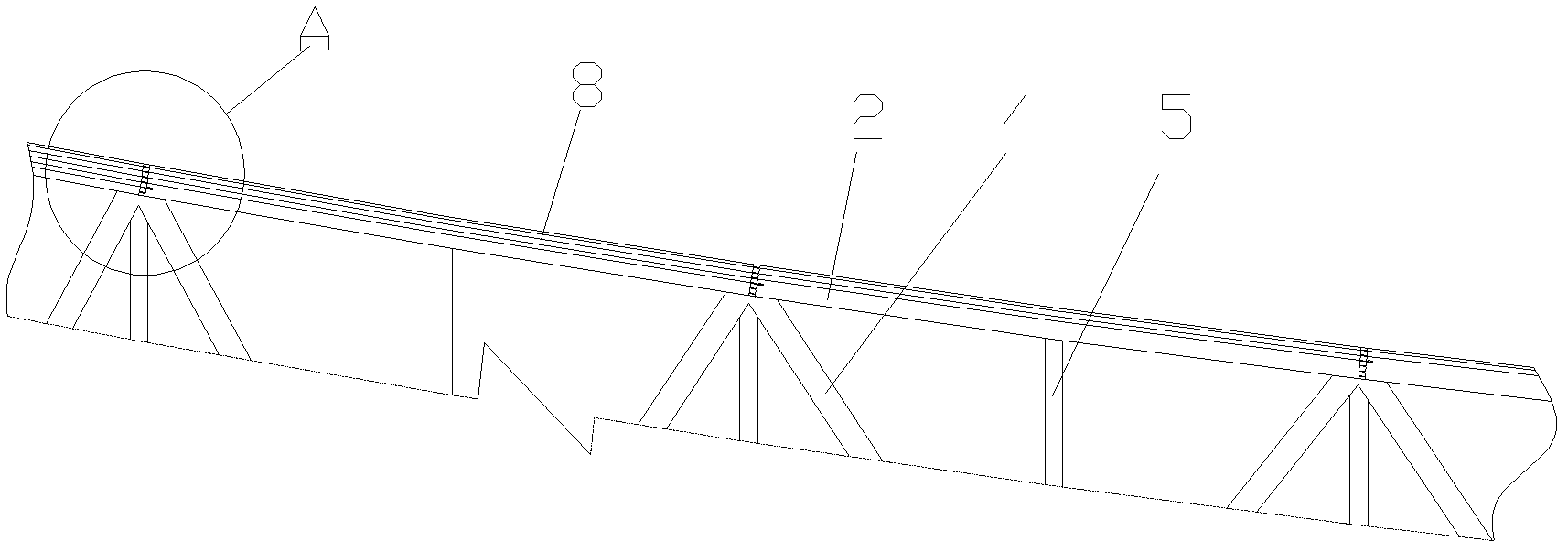

[0040] figure 1 It is a schematic diagram of the main structure of the bridge of the present invention, figure 2 It is a schematic diagram of the main girder side span structure of the present invention, image 3 is the structural diagram of prestressed steel tendons in the upper chord of the main girder close to the bridge pier bearing negative bending moment, Figure 4 It is a schematic diagram of the mid-span beam section of the main girder bearing positive bending moment between adjacent bridge piers, Figure 5 for image 3 Enlarged view at A, Figure 6 is the cross-section diagram of the upper chord of the steel truss girder subjected to negative bending moment near the bridge pier, Figure 7 is the cross-sectional view of the main girder section near the middle pier bearing negative bending moment, Figure 8 is the cross-sectional view of the main girder section bearing positive bending moment in the mid-span between adjacent piers, Figure 9is the cross-sectional...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com