Trigger signal control engine decompression device

A trigger signal and engine technology, applied in engine control, machine/engine, mechanical equipment, etc., can solve the problems of engine fuel consumption, high temperature rise, short gliding distance, etc., and achieve the effect of prolonging gliding distance and remarkable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

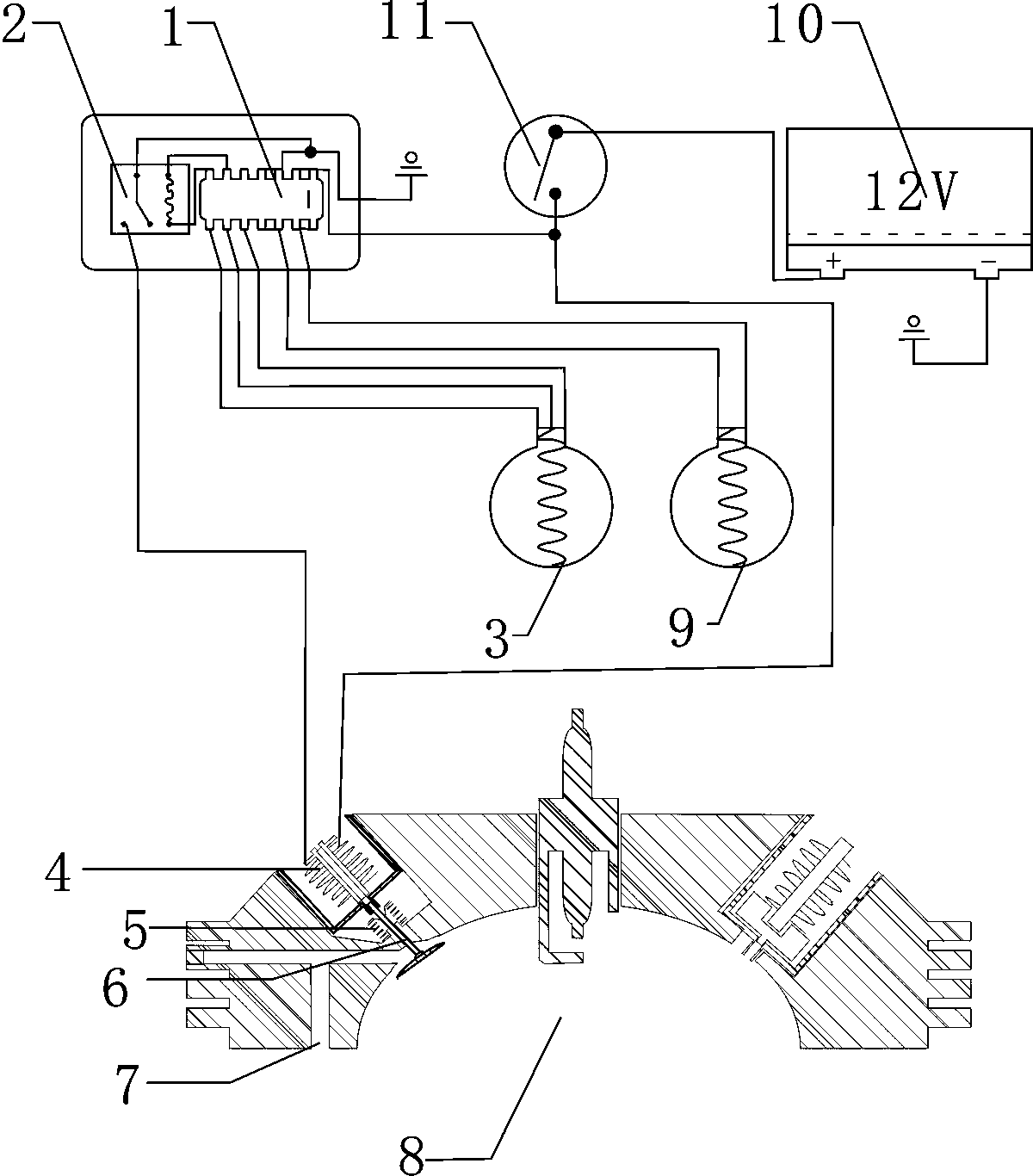

[0008] figure 1 It is a structural diagram of the trigger signal control engine decompression device of the present invention, and its structure is composed of a control chip 1, a relay 2, an accelerator position switch 3, and a motor 4. exist figure 1 Among them, the No. 1 pin and No. 2 pin of the control chip 1, the positive pole line of the motor 4 are connected in parallel with the output end of the power switch 11, and the input end of the power switch 11 is connected with the positive pole of the storage battery 10. The No. 13 pin of the control chip 1, The fourteenth pin is connected to one end of the trigger 9, and the other end of the trigger 9 is connected in parallel with the fifteenth and sixteenth pins of the control chip 1, and the sixth and seventh pins of the control chip 1 are respectively connected to the two pins of the relay 2. The coil end is connected, the eighth, ninth and tenth pins of the control chip 1 are respectively connected with the three ends o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com