Pneumatic variable pitch brake system of wind power generator

A wind turbine and brake system technology, applied in the control of wind turbines, wind turbines, wind power generation, etc., can solve the problems of long transmission distance, low service life, complex transmission mechanism, etc., to ensure the safety of power generation and the failure rate Reduced, direct effect of transmission force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

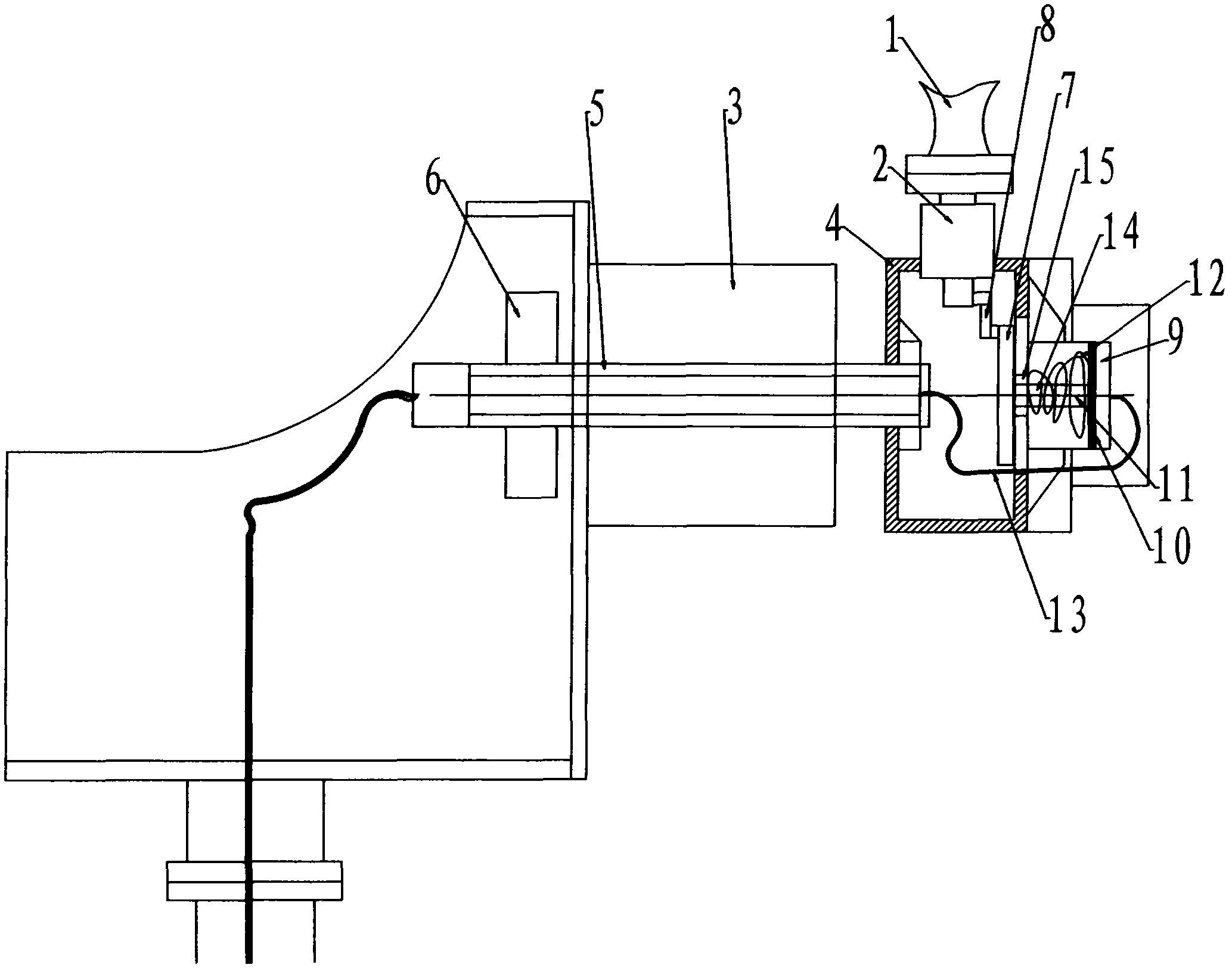

specific Embodiment 1

[0021] Specific embodiment 1: the synchronous disc drive mechanism includes a cylinder 9 fixedly mounted on the front end of the wheel hub 4, a piston 10 and a piston rod 11 are arranged inside the cylinder 9, and one end of the piston rod 11 protruding from the cylinder 9 is connected to the synchronous disc 7 , The piston rod 11 is sheathed with a return spring 12, and the flexible air pipe 13 of the cylinder 9 is connected to the pneumatic system through the rotor shaft 5. The piston rod 11 is provided with a spline 14, and the cylinder 9 is provided with a spline sleeve 15, which acts as a guide. The pneumatic pitch braking system is changed to the front type, the cylinder 9 is placed on the front end of the hub 4, and fixed on the hub 4. When inflating, the gas enters the cylinder 9 from the gas source through the soft air pipe 13, and the gas pushes the piston 10 and the piston rod 11 Push the synchronous disk 7 to move, change the angle of the fan blades, and realize th...

specific Embodiment 2

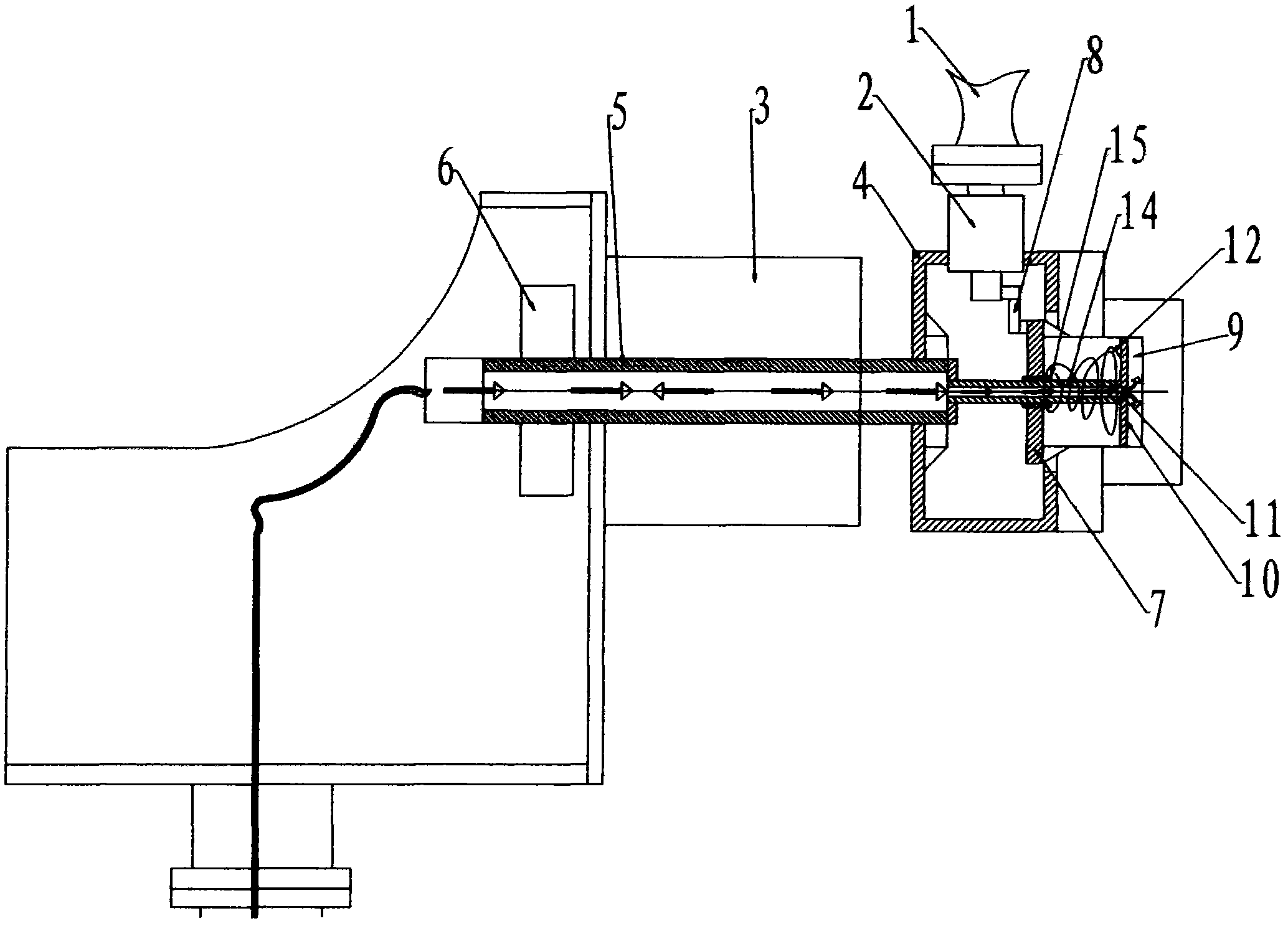

[0022] Specific embodiment 2: the described synchronous disk drive mechanism comprises the cylinder 9 that is installed on the synchronous disk 7, and the inside of the cylinder 9 is provided with a piston 10 and a piston rod 11, and one end of the piston rod 11 extending out of the cylinder 9 is fixed to the rotor shaft 5 Then, the outside of the piston rod 11 is covered with a return spring 12, and the inside of the rotor shaft 5 and the inside of the piston rod 11 are the air passages connected with the pneumatic system. The piston rod 11 is provided with a spline 14 , and the synchronous disc 7 is provided with a spline sleeve 15 . The pneumatic pitch system is changed to the front type, the cylinder 9 is placed at the front end of the wheel hub 4, and the cylinder 9 is fixed on the synchronous disc 7. When inflating, the gas enters the cylinder 9 from the air source through the soft air pipe 13. Since the piston 10 is fixed, the gas pushes the cylinder 9 moves to drive th...

specific Embodiment 3

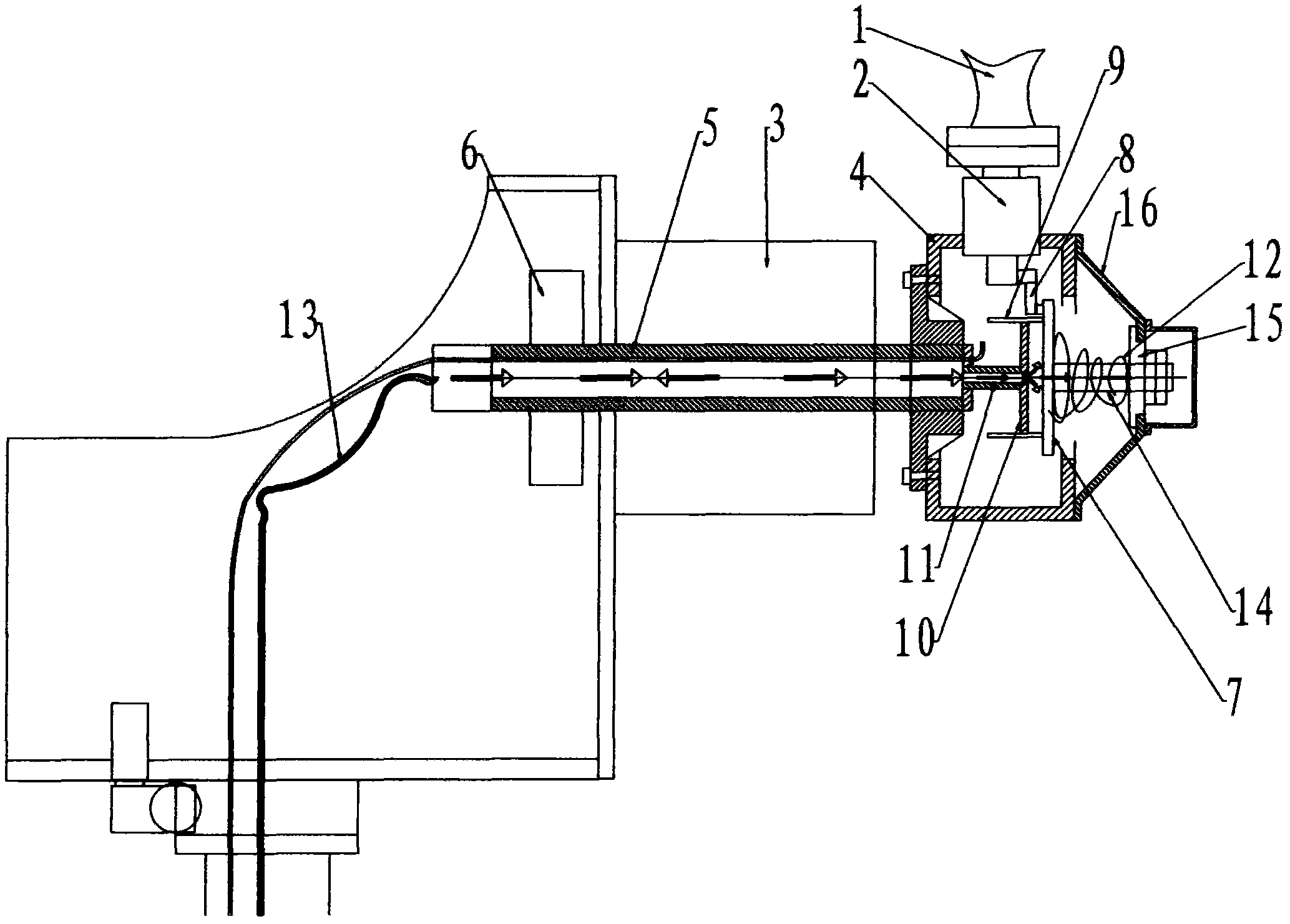

[0023] Specific embodiment 3: The described synchronous disc drive mechanism includes a piston rod 11 and a piston 10 fixed on the rotor shaft 5, a cylinder 9 is arranged outside the piston 10, the cylinder wall is a synchronous disc 7, and the other end of the synchronous disc 7 is A reset device is provided. The resetting device includes a support base 16 installed on the hub, a spline sleeve 15 located on the support base 16, the spline sleeve 15 cooperates with the spline 14, and one end of the spline 14 is fixed on the synchronous disc 7, and the spline sleeve 15 cooperates with the spline 14. A back-moving spring 12 is sheathed on the outside of the key 14 . The pneumatic pitch system is changed to the front type, the cylinder 9 is placed on the front end of the hub 4, the cylinder 9 is fixed on the synchronous disk 7, the return spring 12 is placed outside the cylinder 9, and the front end of the rotor shaft 5 protrudes, which is equivalent to the piston rod 11, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com