Anti-crystallization anti-scaling abrasion-resisting ball valve

An anti-scaling and wear-resistant ball technology, applied in the field of wear-resistant ball valves, can solve problems such as crystallization and scaling, and achieve the effect of long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

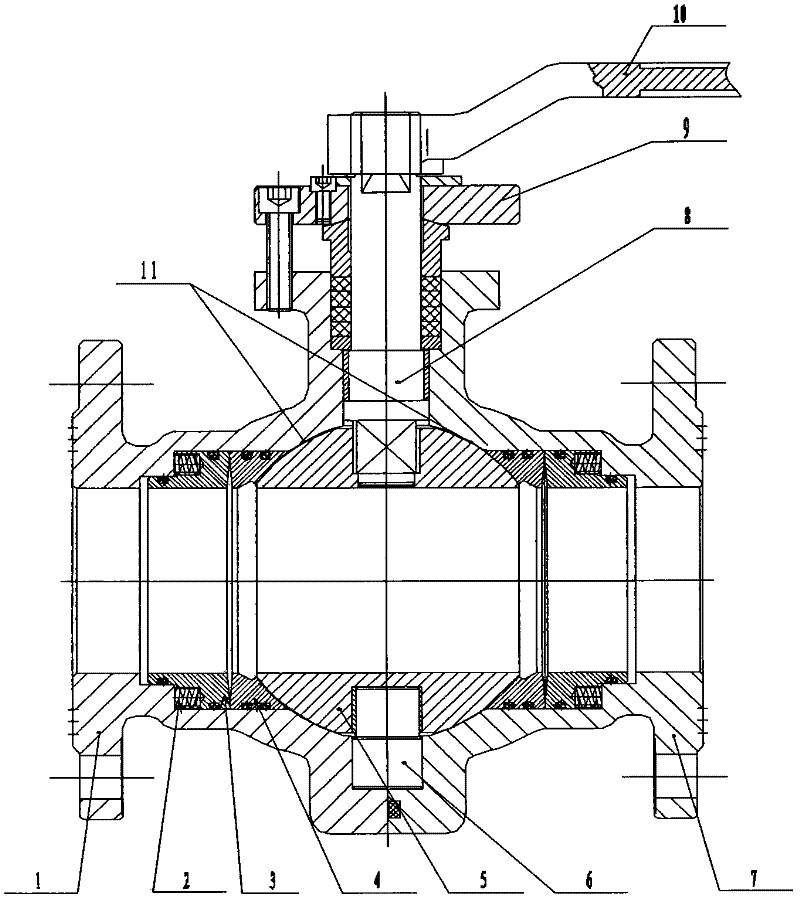

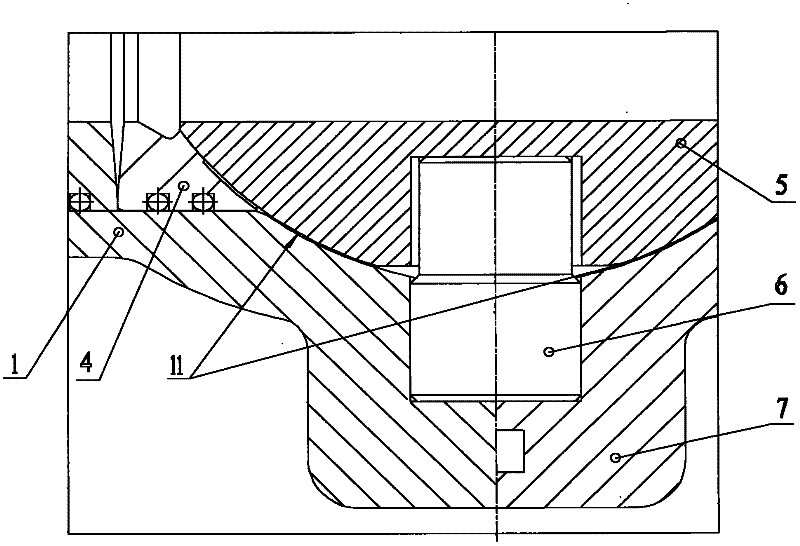

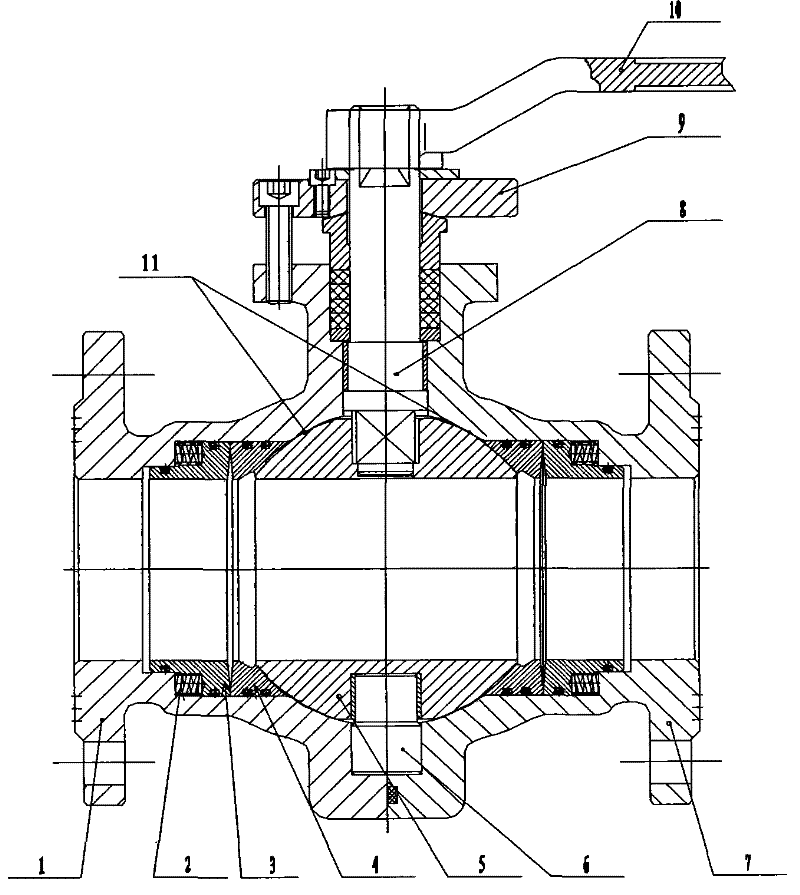

[0010] As shown in the figure, the left valve body 1 and the right valve body 7 form the shell, the left valve body 1, the spring 2, the spring seat 3, the valve seat 4, the ball 5, the valve seat 4, the spring seat 3, the spring 2, and the right valve body 7 are connected in sequence, the handle 10, packing gland 9, valve stem 8, ball 5, and fixed shaft 6 are connected. 5. On the center line of the fixed shaft 6, the geometric shape and size of the inner cavity are symmetrical to each other with the interface as the symmetrical plane. The square tenon at the end of the valve stem 8 is inserted into the tenon groove on the top of the sphere 5, and one end of the fixed shaft 6 is inserted into the sphere. 5. In the blind hole at the bottom, the other end is fixed in the positioning hole formed by the left valve body 1 and the right valve body 7. A slight gap (11) is maintained on the outer surface.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com