Buoyancy automatic control valve

A buoyancy-type, self-control valve technology, applied in the direction of the valve details, valve device, valve shell structure, etc., can solve the problems of high processing precision, abnormal use, easy failure, etc., and achieve a compact and reasonable overall structure. The effect of simplification and volume reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

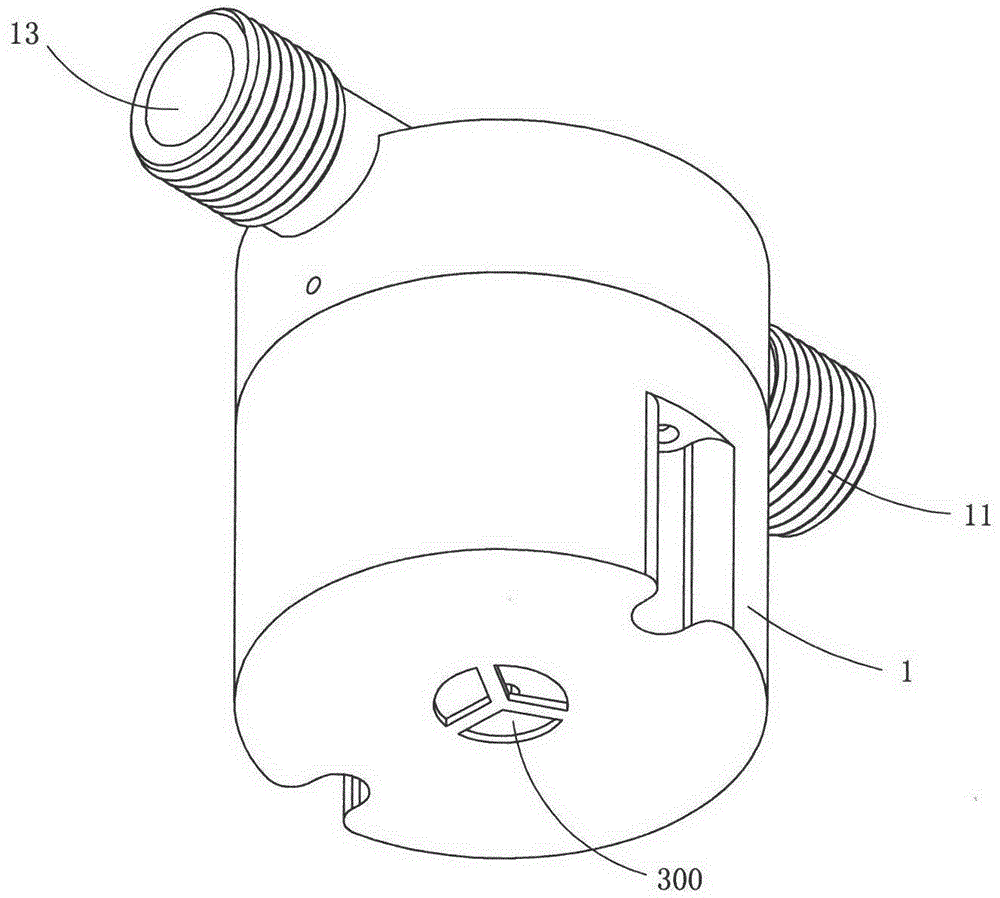

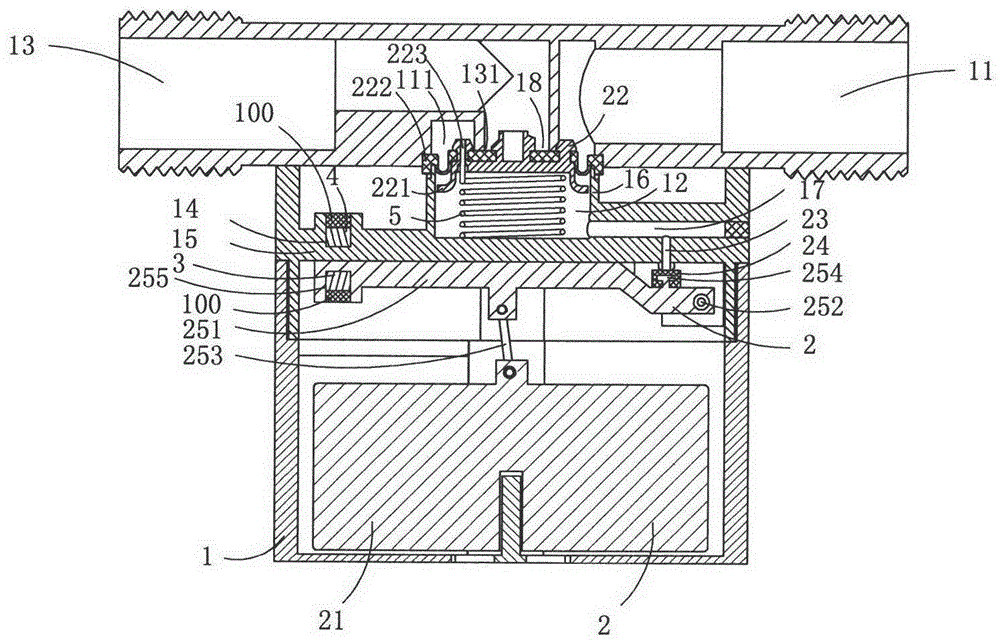

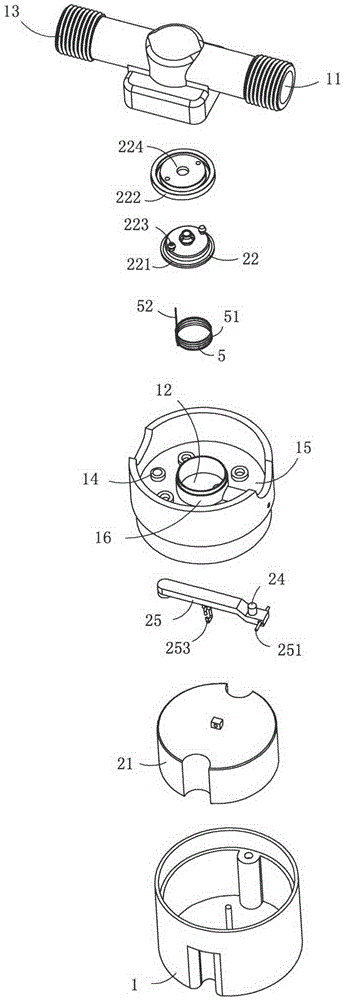

[0022] Figure 1 to Figure 4 A first embodiment of the invention is shown in which, figure 1 It is a schematic diagram of a three-dimensional structure of the present invention; figure 2 for figure 1 A sectional view of the buoyancy self-control valve shown; image 3 for figure 1 An exploded diagram of the buoyancy self-control valve shown; Figure 4 for figure 1 An exploded view of the buoyancy control valve shown when viewed from another angle.

[0023] This embodiment is a buoyancy type self-control valve, see Figure 1 to Figure 4 , including a valve body 1, and a buoyancy on-off component 2 for on-off valve body 1; the valve body 1 includes a water inlet channel 11, a control chamber 18, a water inlet hole 300 and a water outlet channel 13; The center of the control chamber 18 is provided with a pipe body 131 as the water inlet 132 of the water outlet channel 13, and the area between the outer wall of the pipe body 131 and the inner wall of the pressure regulating...

Embodiment 2

[0035] This embodiment is basically the same as Embodiment 1, the difference is that: the water inlet hole 300 on the valve body 1 in this embodiment is no longer like Embodiment 1, only several through holes 300 are set on the valve body, and In Embodiment 1, a through hole is provided, and a convex pipe protruding from the valve body with an external thread is provided. The convex pipe can be used as a pipe joint for connecting with an external water pipe. This structure can make the valve body Embodiments can be used without being placed in a water storage container.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com