10-horsepower variable-frequency multi-connection central air-conditioning unit

A technology for central air conditioning and units, applied in air conditioning systems, space heating and ventilation, household heating, etc., can solve the problems of inconvenient transportation, assembly and installation, thick sheet metal materials, and unstable unit operation. The effect of improving quality stability and reliability, improving strength and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and a preferred embodiment.

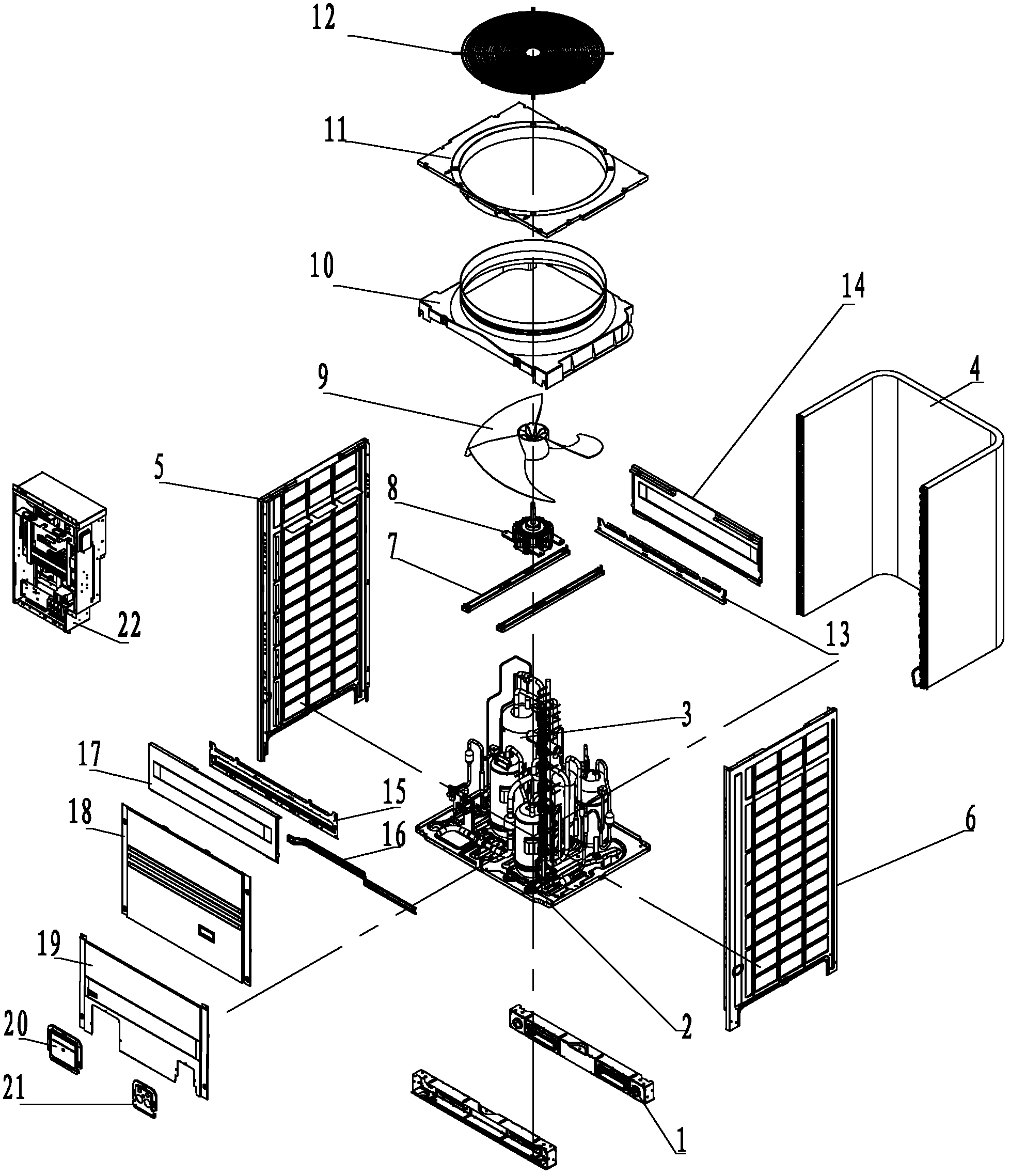

[0037] see Figure 1 to Figure 19 As shown, the ten-horsepower frequency conversion multi-connected central air-conditioning unit in this embodiment includes a machine foot 1, a chassis 2, a compressor pipeline component 3, a condenser assembly 4, a left side panel 5, a right side panel 6, and a motor bracket 7 , DC motor 8, axial fan blades 9, wind guide ring 10, top cover 11, protective net 12, rear beam 13, back panel 14, front upper beam 15, front lower beam 16, upper panel 17, middle panel 18 , Lower panel 19, outlet pipe cover plate 20, outlet pipe cover plate 21, electric control box parts 22 and other parts.

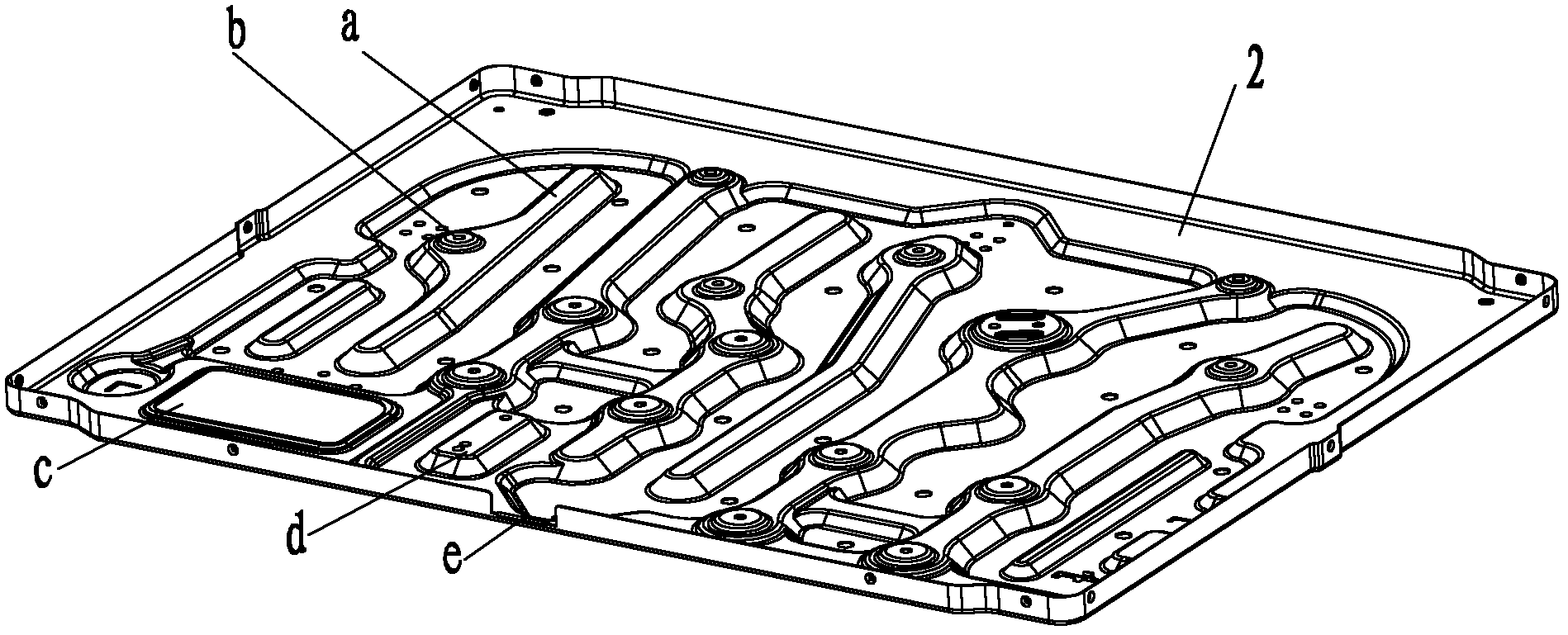

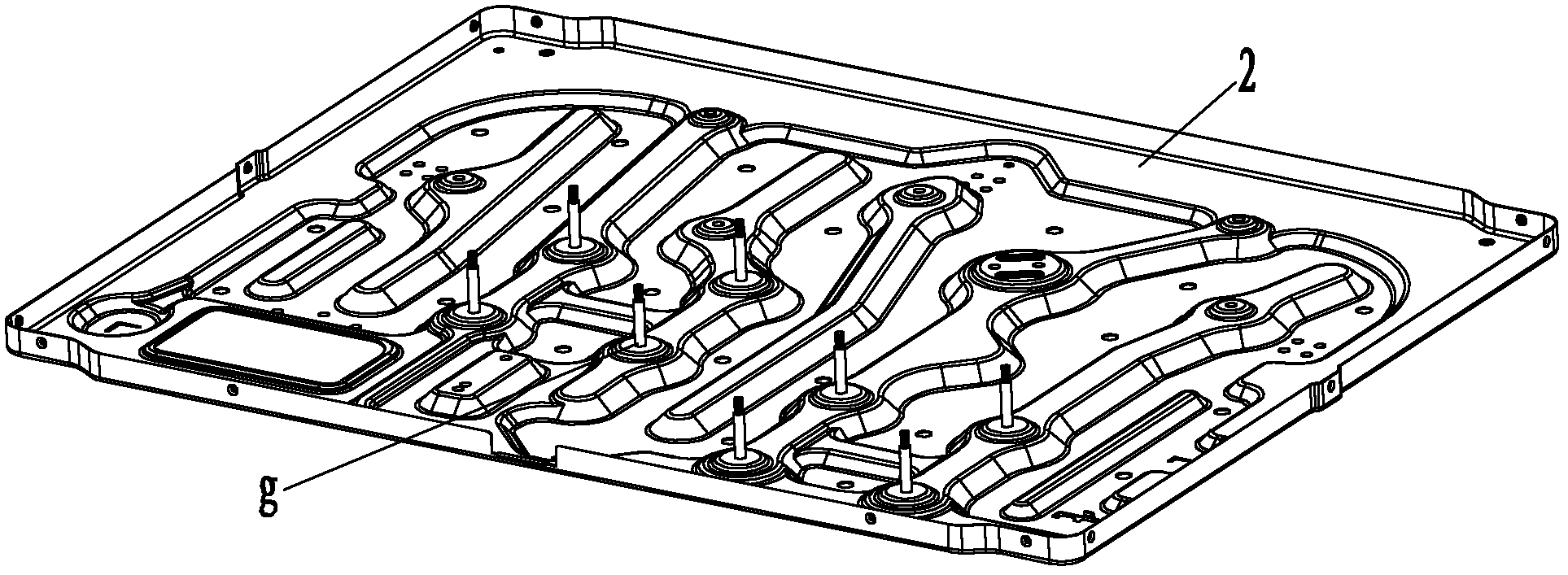

[0038] Among them, see figure 2 , the chassis 2 is stamped from a galvanized steel plate with a thic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com