Inlet electrode sealing device for vacuum furnace

A technology of sealing device and vacuum furnace, which is applied in the direction of furnace, electric furnace heating, furnace components, etc., can solve the problems of seal damage, installation difficulty, vacuum leakage, etc., meet the requirements of installation and use, improve product quality, and have a large room for adjustment Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention is described below in conjunction with accompanying drawing.

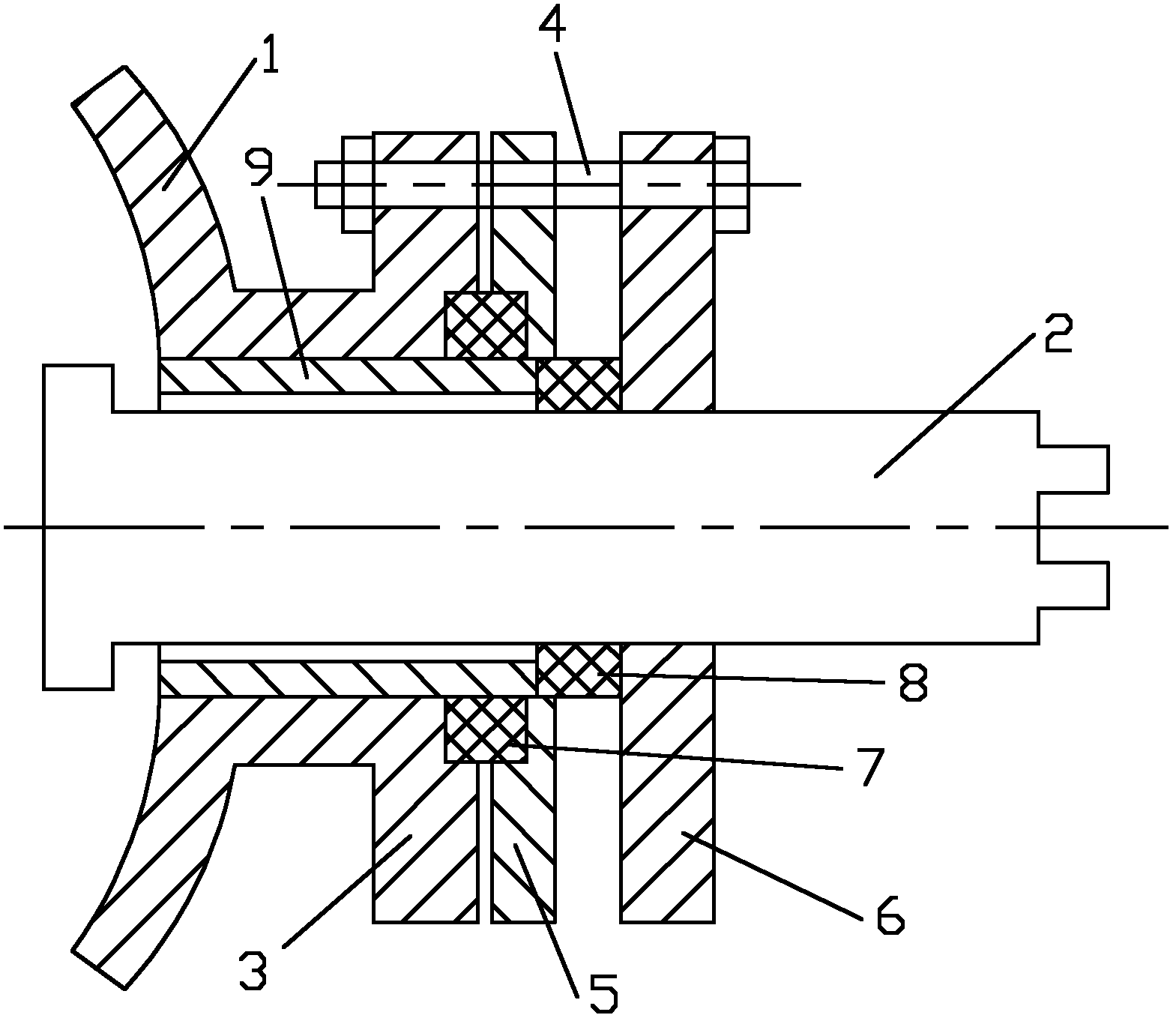

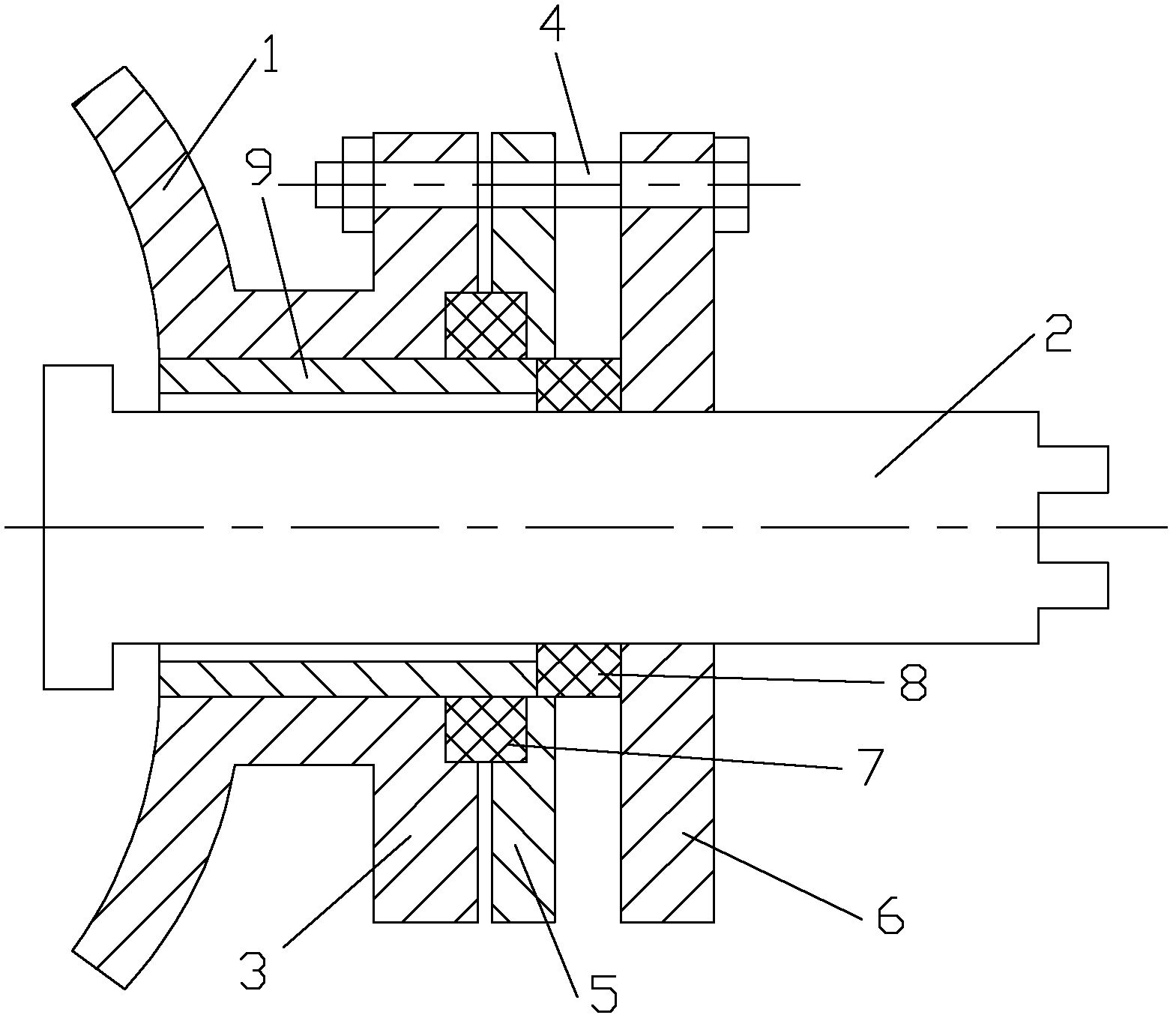

[0016] as attached figure 1 The shown vacuum furnace inlet electrode sealing device of the present invention includes a furnace shell 1 and an inlet electrode 2, the inlet electrode 2 is installed in the furnace shell 1, and an insulating sleeve is provided between the inlet electrode and the furnace shell 9. The furnace shell is provided with a first flange 3; the first flange 3 is connected with a second flange 5 and a third flange 6 through fasteners 4; The end face between the two flanges 5 is provided with a first O-shaped rubber sealing ring 7; the gap between the inlet electrode 2 and the second flange 5 and the third flange 6 is provided with a second O-shaped rubber sealing ring 8; the first flange 3 is made of stainless steel; the second flange 5 is made of insulating material; the insulating material used in the second flange 5 is polytetrafluoroethylene; the inlet electrode...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com