Testing device for imitating shot impact on fuel tank of airplane

A test device and fuel tank technology, which is used in the testing of mechanical components, the testing of machine/structural components, and measuring devices, can solve problems such as time-consuming and cost-effective, and achieve simple manufacturing costs, low costs, and strong test versatility. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

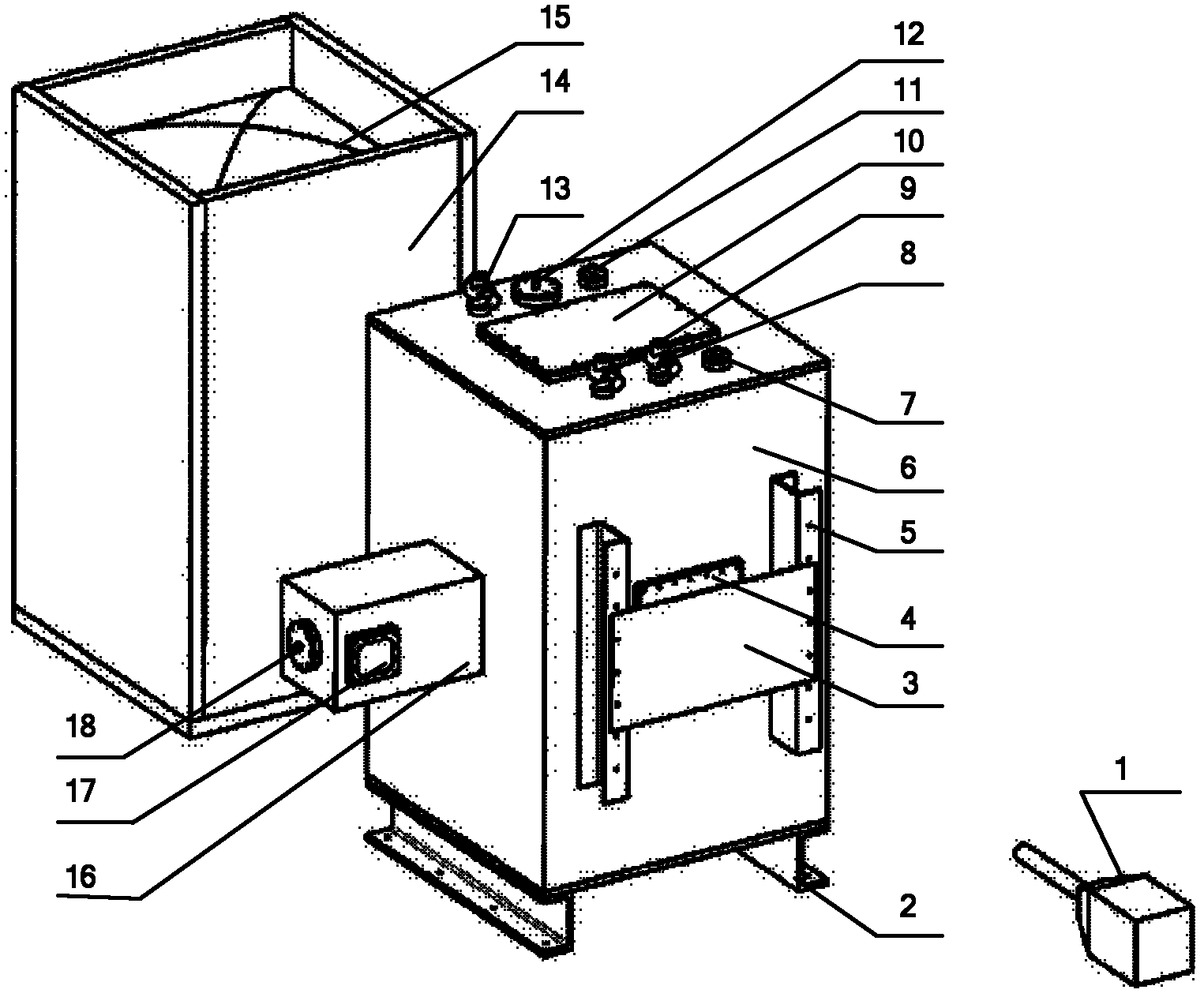

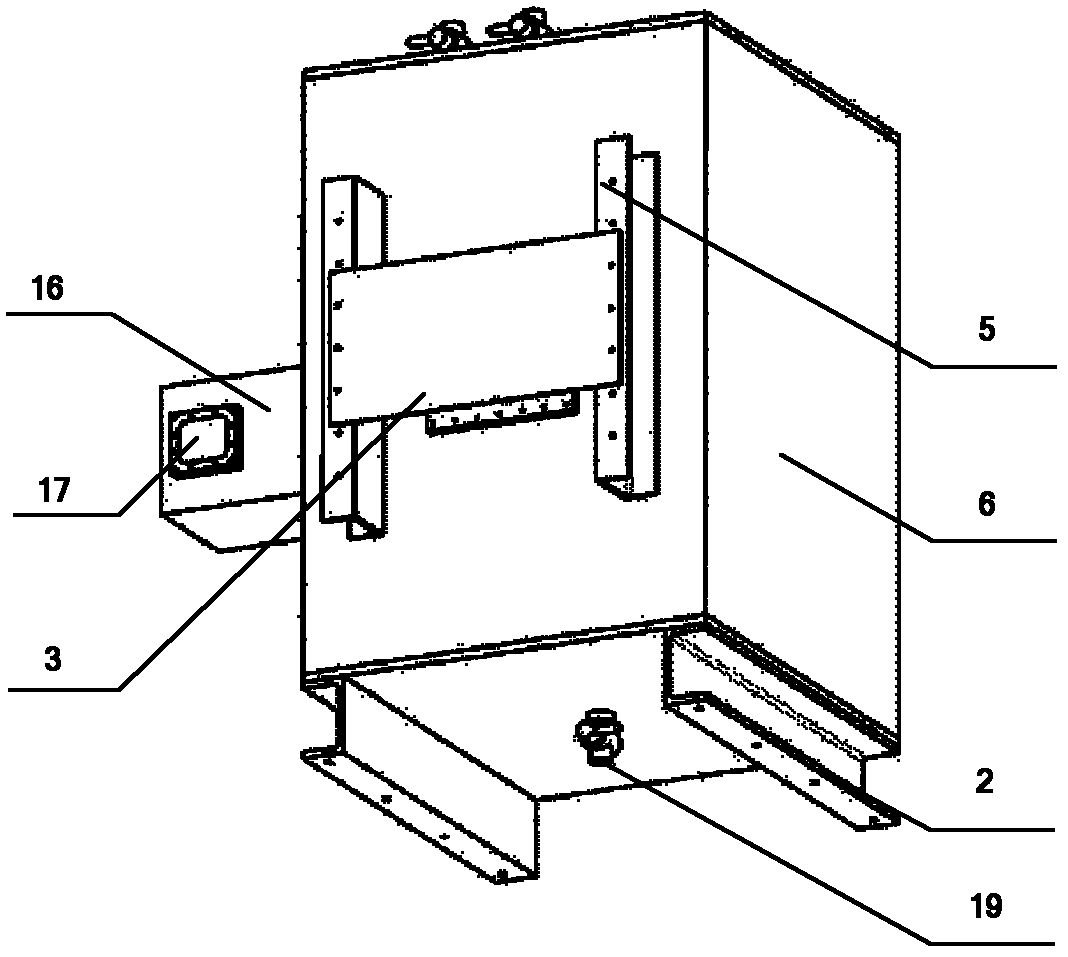

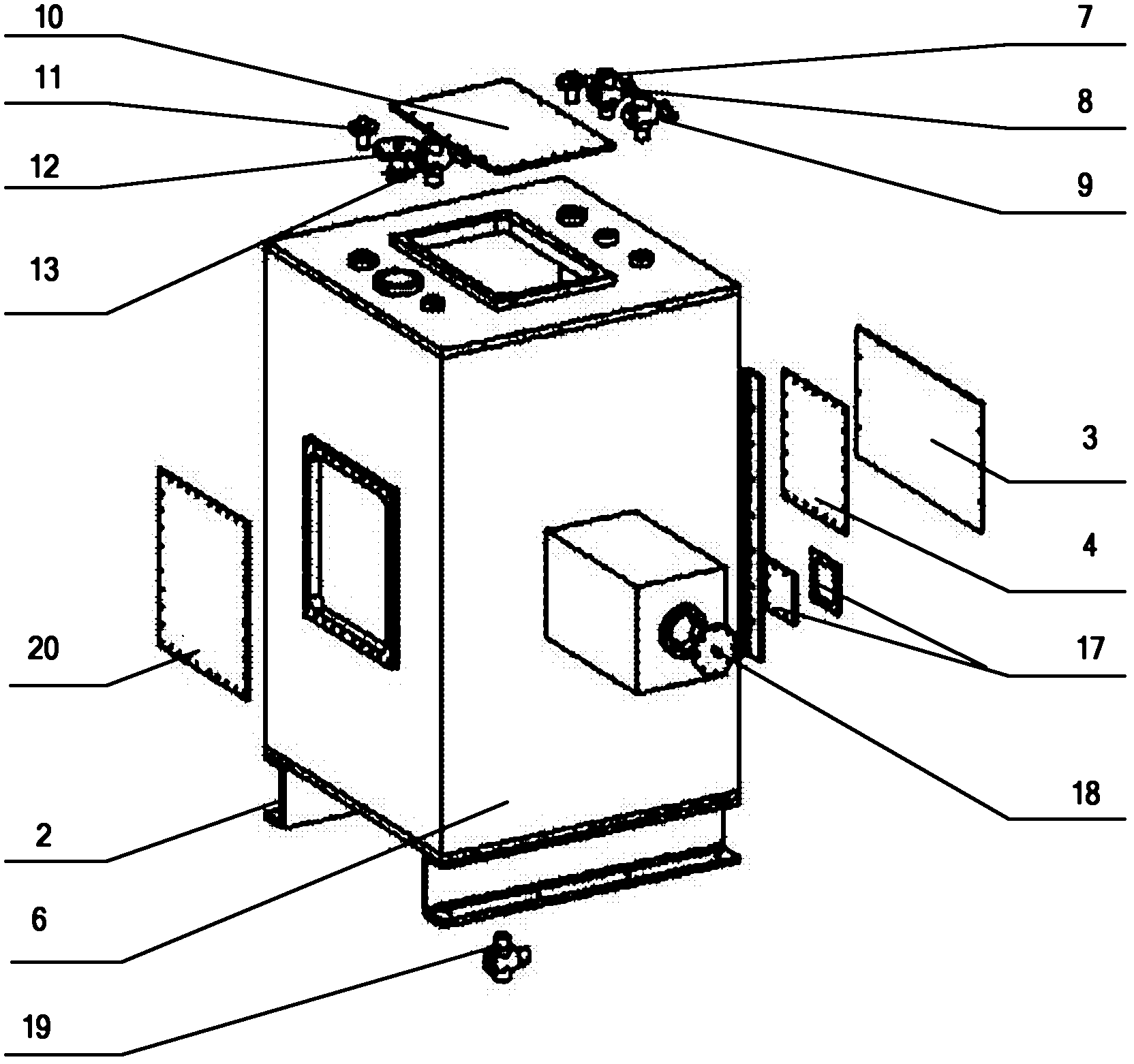

[0020] Provide the specific embodiment of aircraft fuel tank live ammunition shooting test device below in conjunction with accompanying drawing.

[0021] This embodiment includes a pair of base sliders 2 , a fuel tank 6 , a flame propagation observation box 16 and a hollow box 14 . The pair of base sliders 2 are fixed on the lower surface of the fuel tank 6 in parallel, and the fuel tank 6 is matched with the ground rail laid in the test room through the base sliders 2 . The fuel tank 6 is made of a steel plate, and has a pressure relief port at the center of the top plate of the casing, on which a pressure relief plate 10 is installed. An air / oxygen analyzer connecting bolt 7, a vacuum pump connecting bolt 8 and an oil injection port 9 are arranged on one side of the pressure bearing plate 10, and a temperature / pressure measuring instrument is arranged on the other side of the pressure bearing plate 10 Connecting bolt 11, fuel tank fan 12 and air / nitrogen injection port 13,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com