Simulation operation method for rail flaw detection car

A technology of rail flaw detection vehicle and operation method, which is applied in space navigation equipment, material analysis using sonic/ultrasonic/infrasonic waves, instruments, etc., can solve the difficulty of comprehensive on-site verification of the working performance of rail flaw detection vehicles, time, location and cost constraints, Difficulty in operation training and other problems, to achieve the effect of wide coverage, lower cost, and simplified system structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

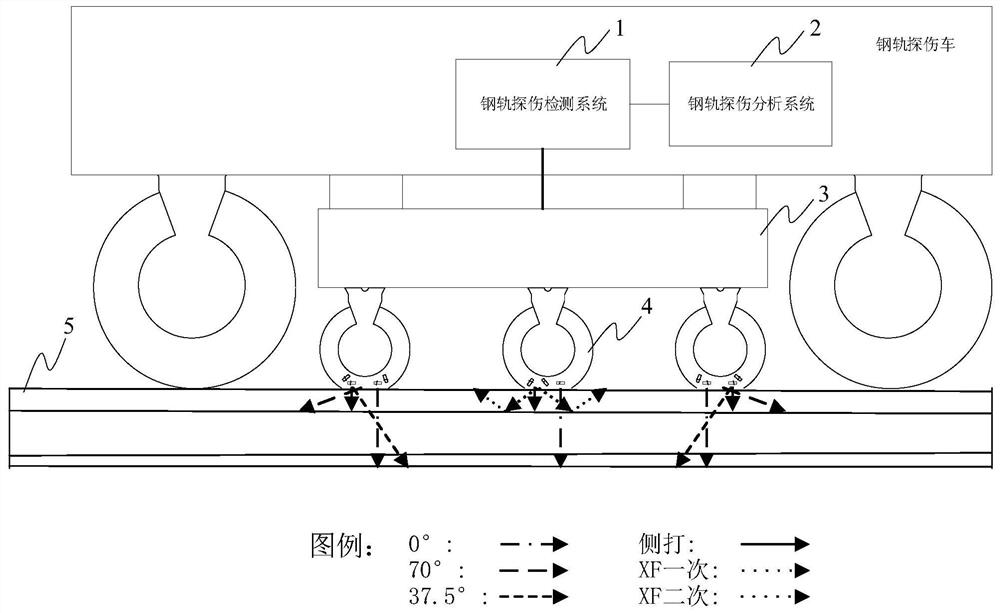

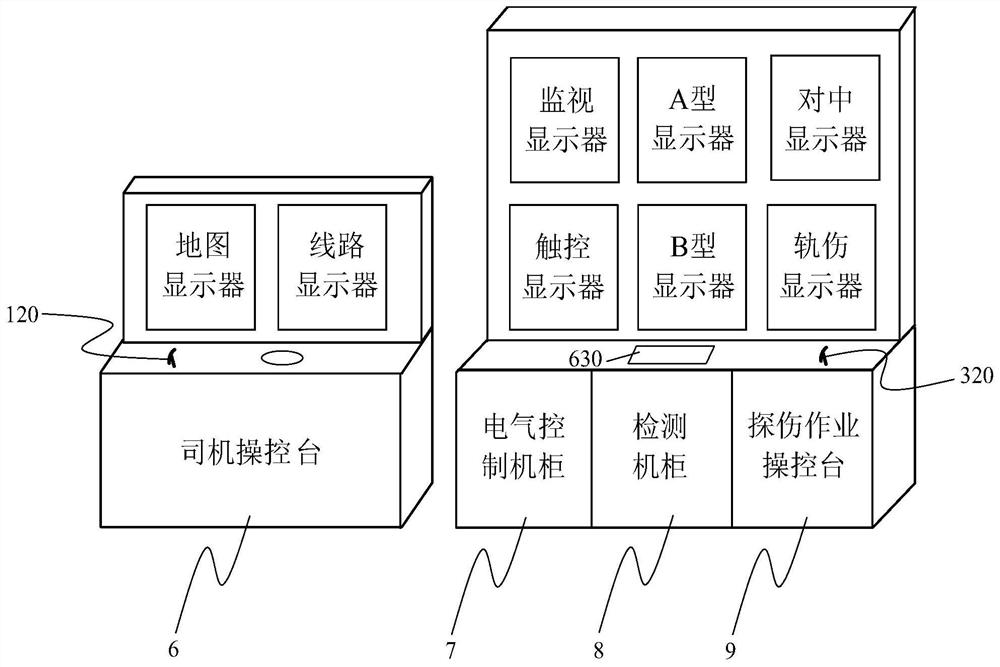

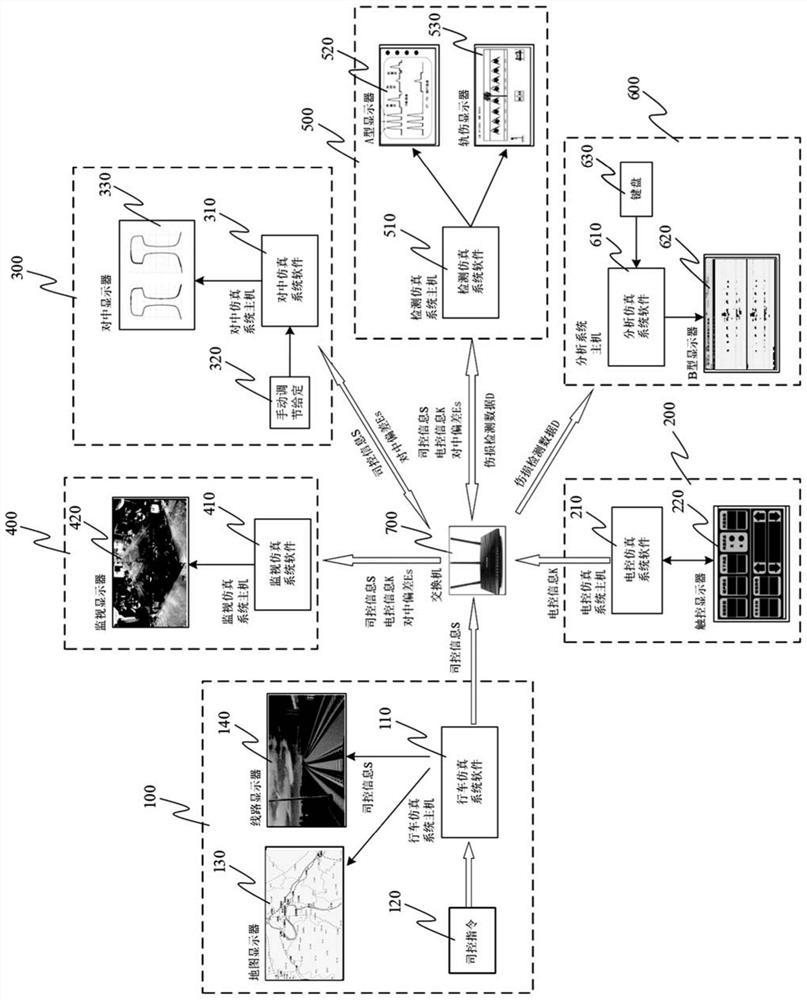

[0065] as attached image 3 As shown, an embodiment of the rail flaw detection car simulation operation based on the method of the present invention specifically includes: a driving simulation system 100 realizing data interconnection through a switch 700, an electronic control simulation system 200, a centering simulation system 300, and a monitoring simulation system 400 . The detection simulation system 500 and the analysis system 600 . Wherein, the driving simulation system 100 is used for simulating the operation of the rail flaw detection vehicle on the rail line. The electronic control simulation system 200 is used to simulate the action of the electronic control system to control the probe wheel 4 . The centering simulation system 300 is used for simulating and controlling the line alignment between the detection wheel 4 and the rail 5 . The monitoring simulation system 400 is used for simulating the running state monitoring screen of the probe wheel 4 . The detecti...

Embodiment 2

[0084] as attached Figure 13 Shown, a kind of embodiment of the simulation operation method of rail flaw detection car based on the system of the present invention, specifically comprises the following steps:

[0085] S10) Use the electronic control simulation system 200 to simulate the pressure adjustment of the probe wheel 4. Before the system simulates driving, turn on the coupling water switch K3, turn on the probe wheel drop switch K2, adjust the air pressure P of the probe wheel, and obtain the probe wheel depression amount H= f(P), observe the A-type display 520 probe wheel 0 degree chip ultrasonic emission initial pulse and interface wave delay meet the specified value T D , the adjustment of the probe wheel depression H is completed.

[0086] S20) Simulate the flaw detection route through the driving simulation system 100, select the driving route composed of station name sequences through the map display 130, and the driving simulation system 100 simulates the oper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com