Ultrahigh-speed motor, electric air compressor and new energy automobile

A technology of high-speed motors and casings, which is applied in the direction of electric components, electromechanical devices, electrical components, etc., and can solve problems such as the lack of in-depth research on the structure of ultra-high-speed motors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

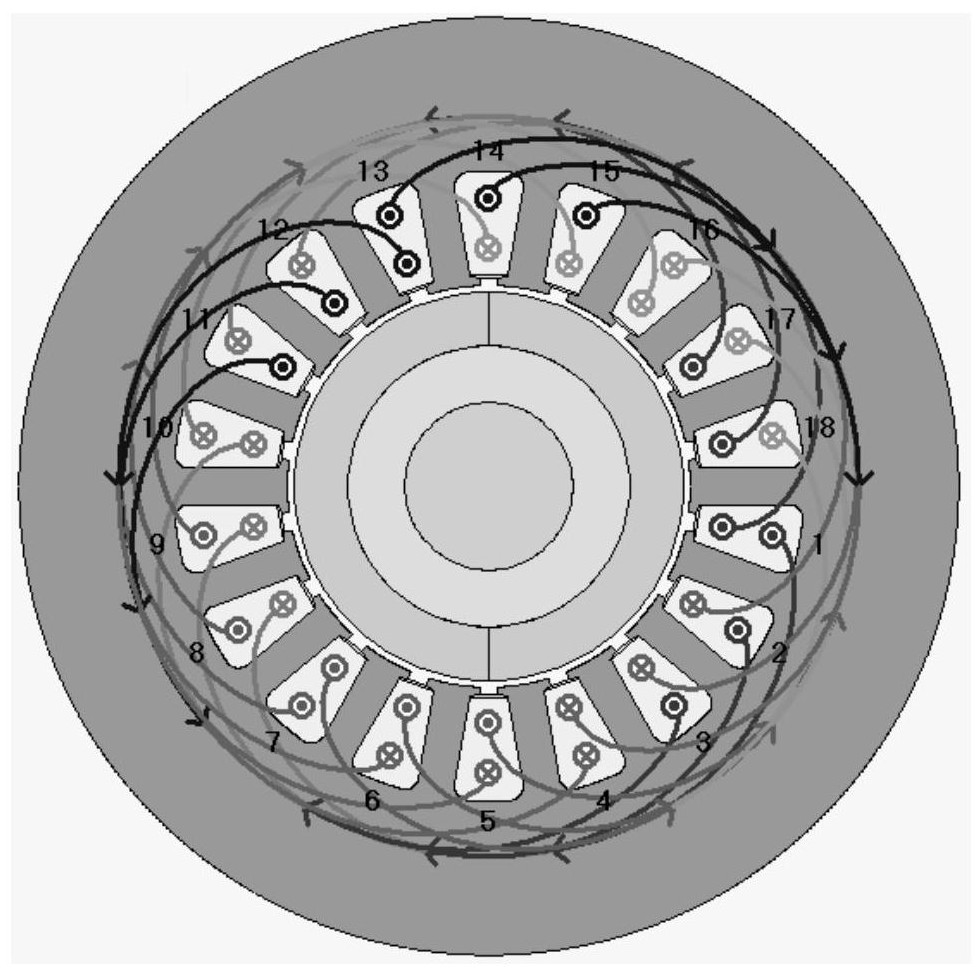

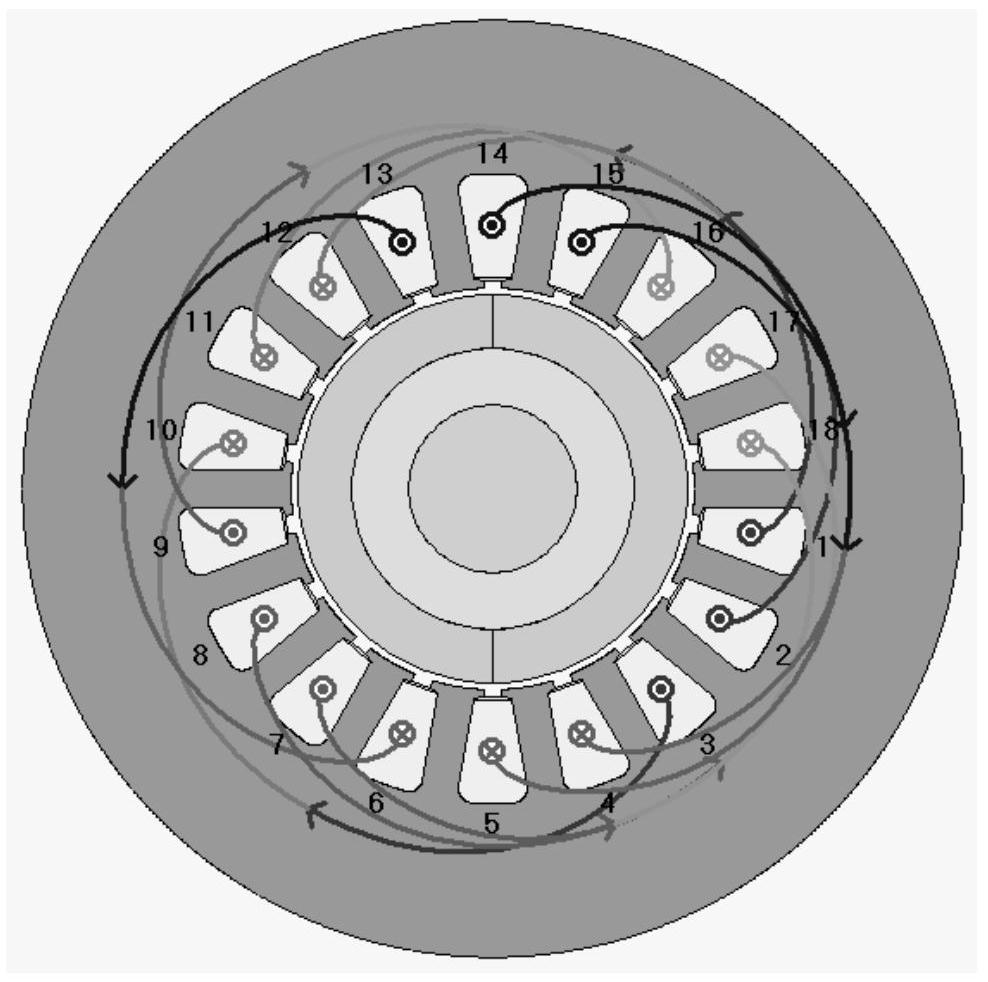

[0060] First Research Question: Comparative Analysis of Windings

[0061] Table 1 compares the performance of single-layer winding and double-layer winding. The results show that the efficiency, output power and loss of double-layer winding and single-layer winding are not much different.

[0062] For ultra-high-speed motors, due to the small inner diameter of the motor stator, the double-layer winding is not easy to insert wires. Although the overall performance of the single-layer winding scheme is reduced, compared with the double-layer winding, the performance difference of the motor is not large, so the single-layer winding with good manufacturability that is conducive to mass production is selected.

[0063] Table 1

[0064] system efficiency Output Power total loss 2 pole double layer winding 96.75 10466 351.6 2 pole single layer winding 96.857 11119 360.9

[0065] The second research question: comparative analysis of pole number sc...

Embodiment 1

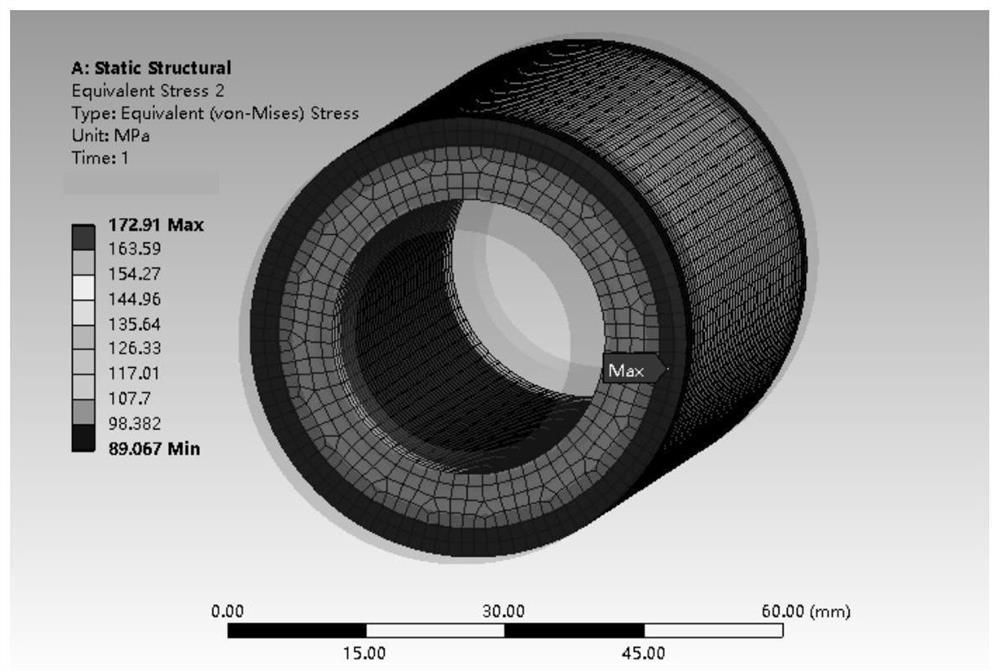

[0098] Embodiment 1: Water-cooled casing, increasing the number of stator core openings: 12 square holes of 2 mm × 5 mm near the inner circumference of the stator core 2-1, and 12 square slots of 2.5 mm × 6 mm in the outer circle. 16 fans are installed on both sides of the magnetic ring protective cover for the three-dimensional rotating shaft, and 12 long strip holes of 2mm×20mm are opened in the magnetic ring protective cover. model such as Figure 22a As shown, the simulation results are as Figure 22b shown. From Figure 22b It can be seen that the internal air has axial radial convection

[0099] Table 3 shows the comparative results of Comparative Example 1, Comparative Example 2, Comparative Example 3, Comparative Example 4, Comparative Example 5 and Example 1 above.

[0100] It can be seen from Table 3 that the design of the present application has good effects and can meet the needs of high-speed motors.

[0101] That is: in this application: set multiple second ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com