Method for rapidly detecting non-dairy creamer in adulterated fresh milk

A lipid-based, fast technology, applied in the direction of chemical reaction of materials for analysis, chemiluminescence/bioluminescence, etc., can solve problems such as poor specificity, and achieve the effects of low cost, rapid detection, and suitable sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

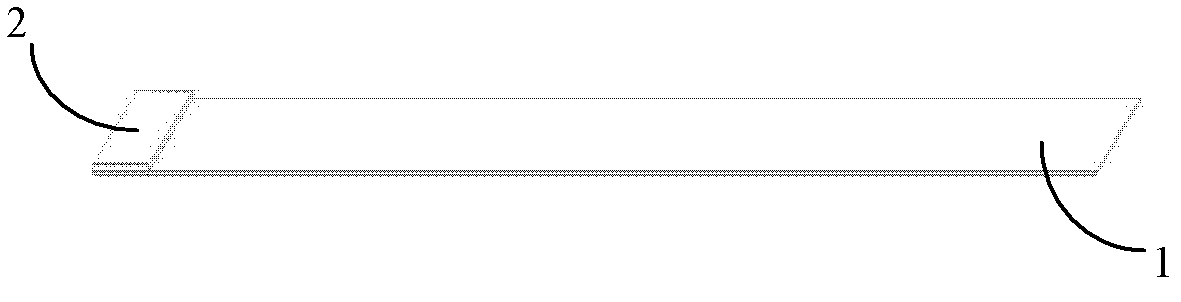

Image

Examples

Embodiment 1

[0022] The detection reagent of non-dairy creamer in embodiment 1 milk

[0023] Preparation of liquid A:

[0024] Add 400ml of high-purity water into a 1000ml beaker (the resistivity is required to be above 18M), put it on a magnetic stirrer, and add 2g of hydroxymethylcellulose sodium salt (CMC-requires white appearance, low molecular weight, and low viscosity) while stirring, 3.5 g of anhydrous citric acid (analytically pure) and 4.25g of a crystalline water sodium citrate (analytical pure), heated to 60-65°C, stirred for about 20 minutes to dissolve completely, stopped heating, and when the solution dropped to room temperature, added while stirring 2ml 10% RHODAFAC RE960 stabilizer (nonylphenol phosphate), 4g glucose oxidase (126U / mg) (purchased from Sigma, USA), 1g peroxidase (114U / mg) (purchased from Sigma, USA), 10ml 2% thiazole yellow (purchased from Sigma, USA) was stirred for about 30 minutes to dissolve completely, and the volume was adjusted to 500 ml with high-pur...

Embodiment 2

[0027] The detection reagent of non-dairy creamer in embodiment 2 milk

[0028] Preparation of liquid A:

[0029] Add 400ml of high-purity water into a 1000ml beaker (the resistivity is required to be above 18M), put it on a magnetic stirrer, and add 4g of hydroxymethylcellulose sodium salt (CMC-requires white appearance, low molecular weight, and low viscosity) while stirring, 3.5 g of anhydrous citric acid (analytically pure) and 4.25g of a crystalline water sodium citrate (analytical pure), heated to 60-65°C, stirred for about 20 minutes to dissolve completely, stopped heating, and when the solution dropped to room temperature, added while stirring 2ml10% triphenyl phosphite, 2g glucose oxidase (126U / mg) (purchased from Sigma, U.S.), 0.7g peroxidase (114U / mg) (purchased from Sigma, U.S.), 40ml2% reactive yellow (purchased from Sigma, U.S. (from the U.S. Sigma Company), stirred for about 30 minutes to dissolve completely, and dilute to 500 ml with high-purity water, and set...

Embodiment 3

[0032] The detection reagent of non-dairy creamer in embodiment 3 milk

[0033] Preparation of liquid A:

[0034] Add 400ml of high-purity water into a 1000ml beaker (resistivity must be above 18M), put it on a magnetic stirrer, and add 6g of polyvinyl alcohol, 3.5g of anhydrous citric acid (analytical pure) and 4.25g of a crystalline water of citric acid while stirring Sodium (analytical pure), heated to 60-65 ° C, stirred for about 20 minutes to dissolve completely, stop heating, after the solution has cooled to room temperature, add 2ml 10% RHDAFAC RE960 stabilizer, 3g glucose oxidase (126U / mg) while stirring (purchased from U.S. Sigma Company), 1.5g peroxidase (114U / mg) (purchased from U.S. Sigma Company), 20ml 2% acid yellow (purchased from U.S. Sigma Company), stirred for about 30min to dissolve completely, and settled to volume with high-purity water to 500 ml, set aside.

[0035] Preparation of liquid B:

[0036] Add 300ml anhydrous toluene (reagent grade) in the 10...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com