Method and apparatus for laminography inspection

A detector, X-ray technology, used in instruments for radiological diagnosis, material analysis using radiation, material analysis using wave/particle radiation, etc., can solve problems such as reduced efficiency, high monetary cost, and complex gantry

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

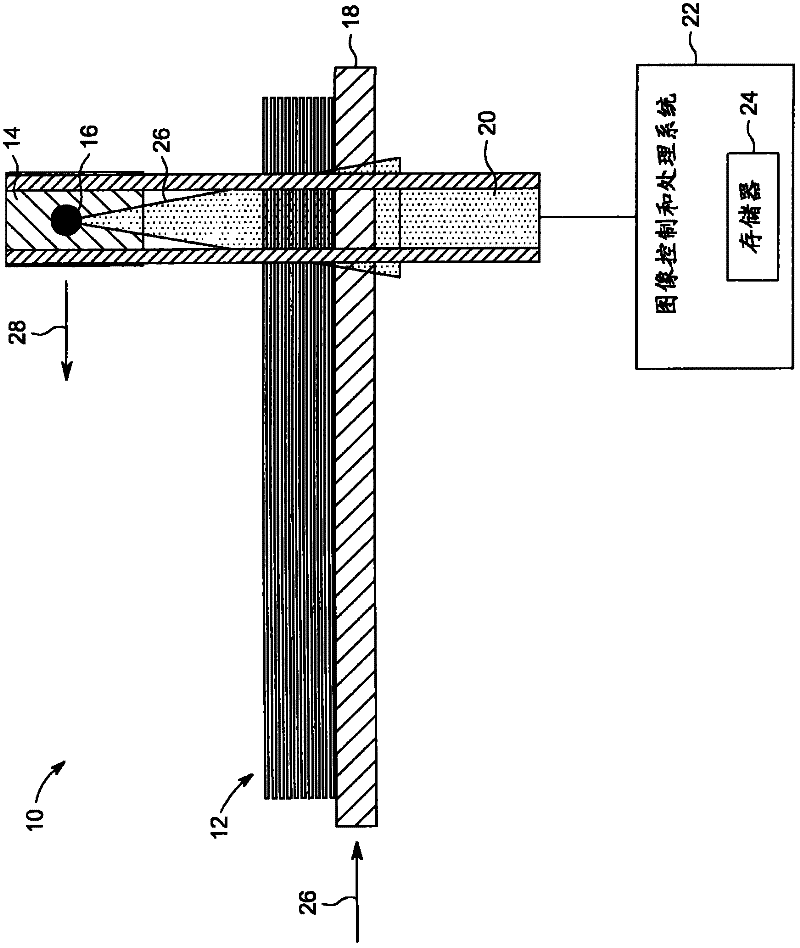

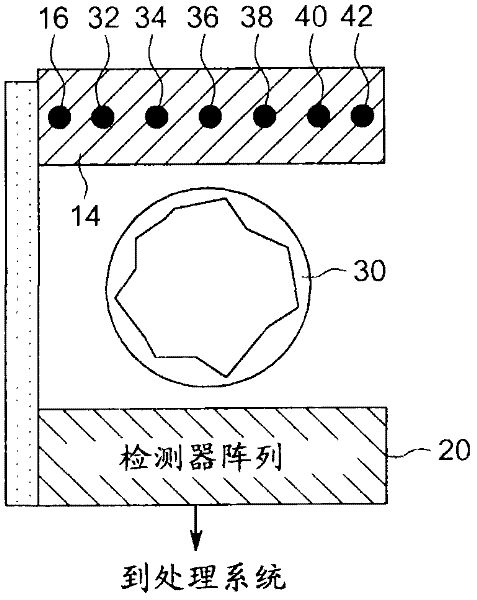

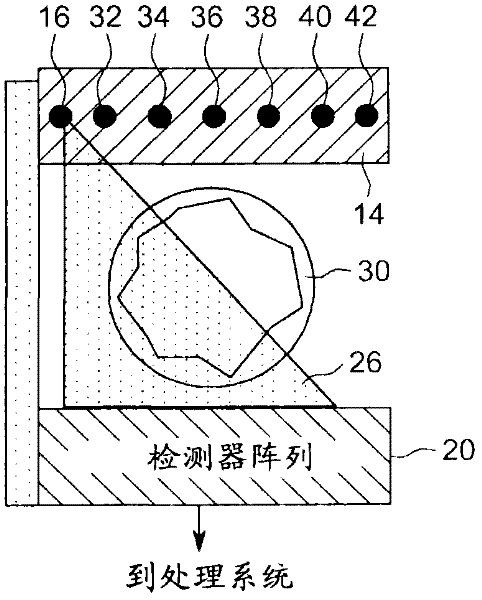

[0020] As described in detail below, embodiments of imaging systems are provided that include a substantially stationary multi-focus X-ray source that generates angularly displaced X-rays that illuminate an object prior to detection by a detector. Such systems are able to obtain a complete set of planar images of the object on an arc while remaining substantially fixed; this set of planar images can be used to reconstruct slices at different planes in the object. For example, in one embodiment, a processor of the laminar photographic inspection system may use the set of planar images to reconstruct a pipe slice, determine the wall thickness of the pipe, and determine the presence and location of defects in the pipe. Furthermore, in some embodiments, slices of an object (eg, pipe) can be reconstructed via a move-and-add step, and then mathematical deblurring techniques can be used to improve image quality and slice sensitivity curves.

[0021] The above-described features of em...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com