Method and system for parallelizing axis of reflecting surface and rotation axis of Dove prism

A technology of Dowell prism and reflective surface, applied in installation, optics, instruments, etc., can solve the problems of complex process, low adjustment accuracy, deformation of Dowell prism, etc., to improve assembly accuracy, simple system structure, and ensure parallelism. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

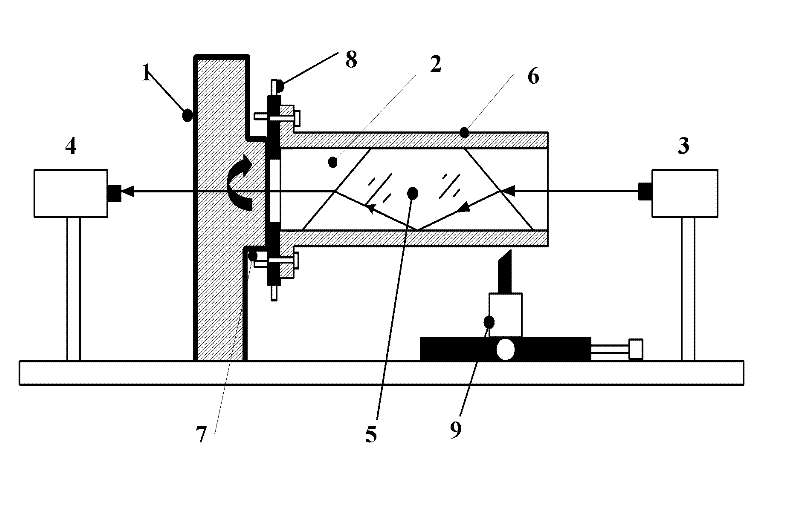

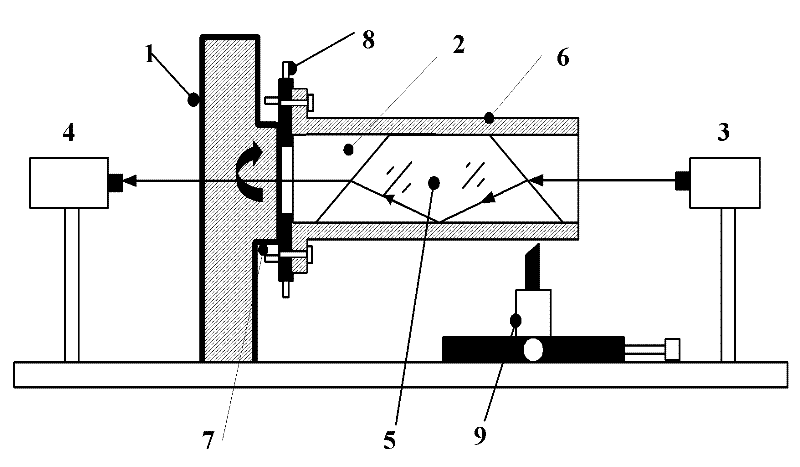

[0026] The present invention relates to a method for realizing that the axis of the reflective surface of the Dove prism is parallel to the axis of rotation, the method includes the following steps:

[0027] Step 1: Install the Dove prism assembly on the lathe, and the Dove prism assembly is driven by the spindle of the lathe to perform high-speed and precise rotation;

[0028] Step 2: Adjust the installed Dove prism assembly so that the axis of the reflective surface of the Dove prism is parallel to the main axis of the lathe; specifically include:

[0029] Step 2.1: Adjust the emitting source and receiving source of the parallel light so that the optical axis is coaxial and parallel to the main axis of the lathe;

[0030] Step 2.2: Adjust the inclination angle and displacement of the Dove prism assembly so that its optical axis is parallel to the optical axes of the parallel light emitting source and receiving source. Usually the displacement is controlled within the range ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com