Novel temperature/humidity controller

A temperature and humidity sensor, temperature and humidity technology, used in non-electric variable control, control/regulation systems, and simultaneous control of multiple variables, etc., can solve the problems that the starting control point cannot be changed, the temperature difference is large, and the accuracy is poor. Achieve the effect of good anti-condensation effect, intuitive interface and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

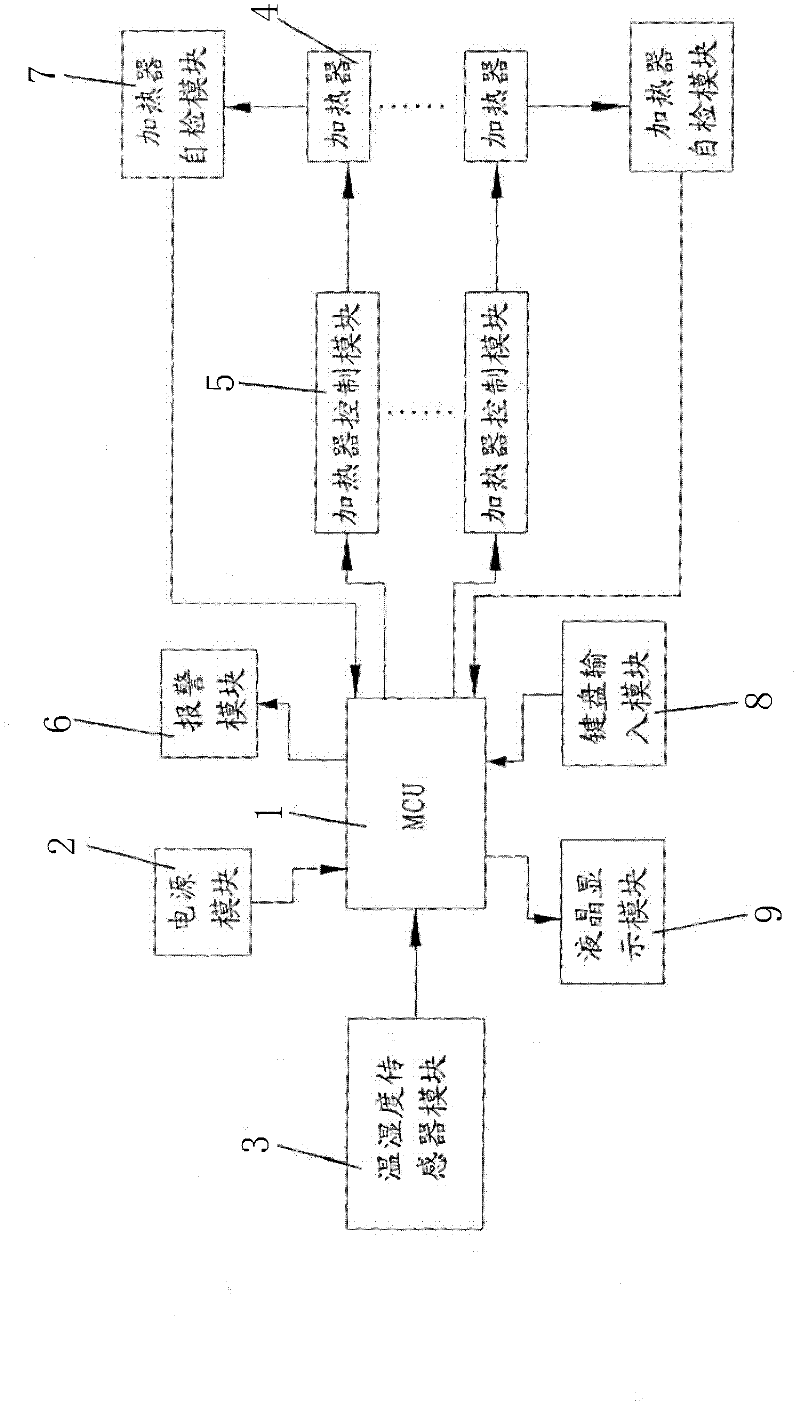

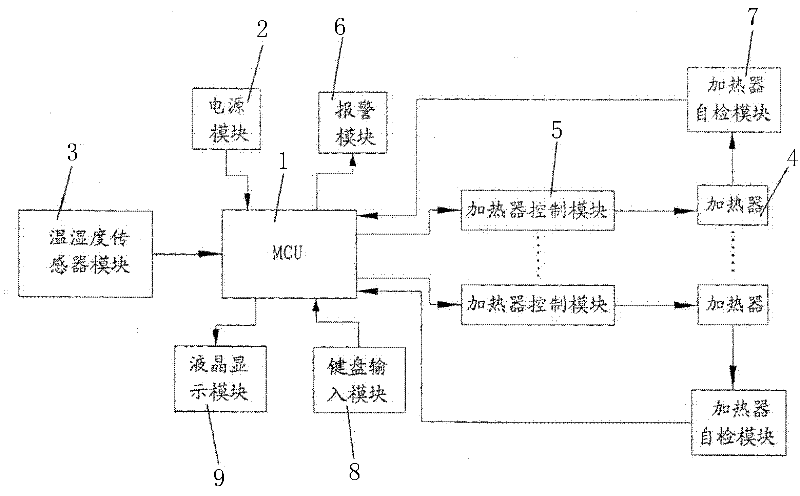

[0009] Such as figure 1 Shown, the present invention is connected with power supply module 2, temperature and humidity sensor module 3, alarm module 6, keyboard input module 8 and liquid crystal display module 9 on MCU microcontroller 1, two heater control modules 5 are connected with MCU micro-controller respectively The device 1 is connected to two heaters 4, the two heaters 4 are connected to two heater self-test modules 7 respectively, and the two heater self-test modules 7 are connected to the MCU microcontroller 1 respectively. Through the above settings, the power module 2 of the present invention

[0010] Provide working voltage for MCU microcontroller 1, and provide working voltage for other components through MCU microcontroller 1. The temperature and humidity sensor module 3 includes a digital temperature and humidity sensor integrated with a temperature sensor and a humidity sensor, and the two are set together. By using a digital sensor, the response speed and ac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com