Heat vulcanization repairing method of cable connector and mould for repairing

A cable joint, thermal vulcanization technology, used in circuits, connections, electrical components, etc., can solve the problem of increasing the ground potential, waterproofing of high-voltage cables, poor pressure resistance, tensile resistance and wear resistance, normal production of equipment and personal injury. Safety and inconvenience and other issues, to achieve the effect of good practicability, tensile and wear resistance and other excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

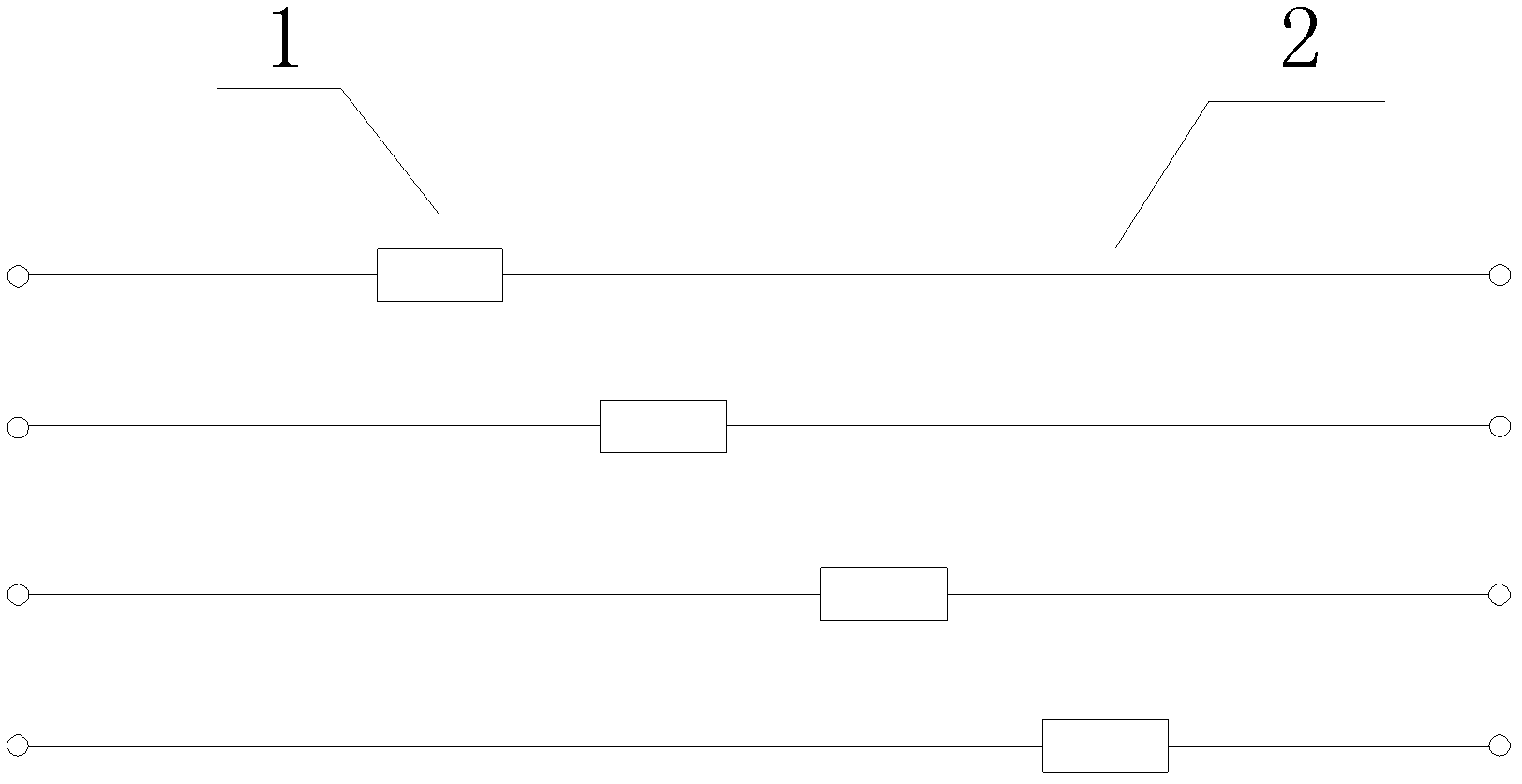

[0019] combine figure 1 , the length of the cable breach is about 400mm. In terms of the treatment of the cable core wires, the thermal vulcanization repair method connects the joints of the four copper core wires 2 with a Ф35mm*50mm copper pipe 1, and the joints are evenly staggered. Wrap the high-voltage waterproof tape to ensure the insulation between the copper core wires.

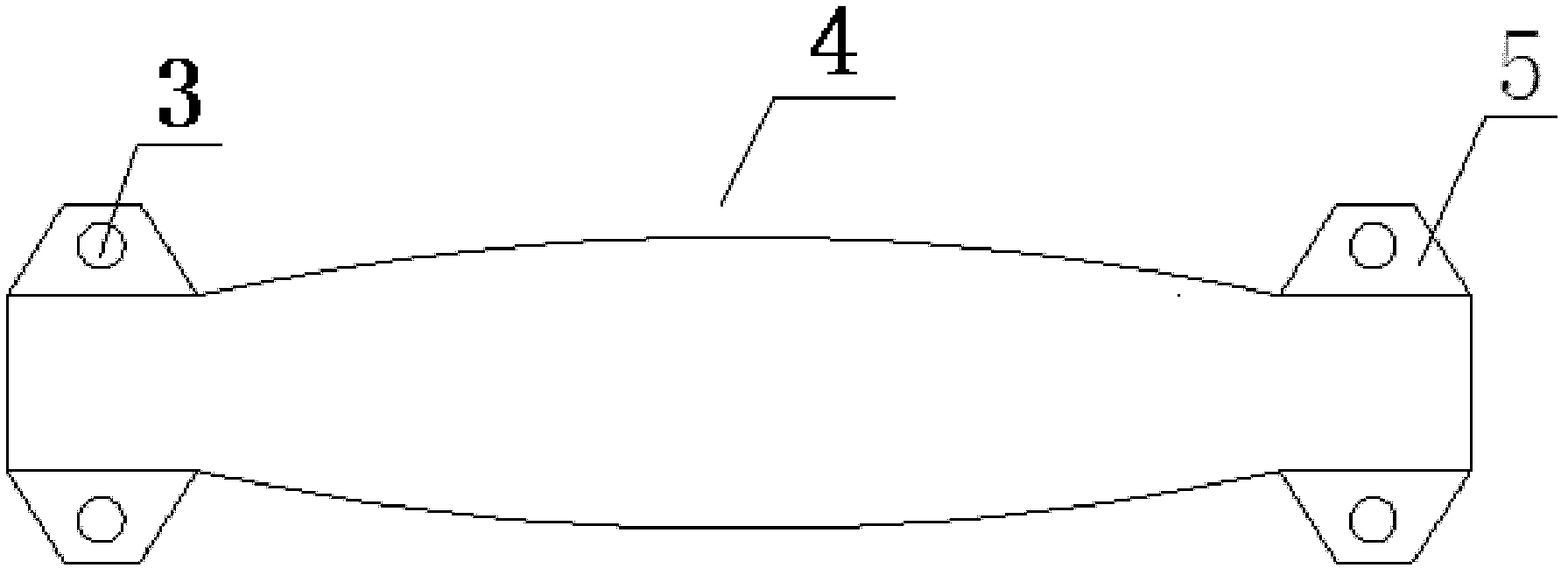

[0020] combine figure 2 , wrap the processed four copper core wires tightly with hot-vulcanized rubber belts, and control the diameter of the joints at about 90-95mm after wrapping; then use the prepared cable mold 4 to clamp them tightly. The gap between the cavity and the copper core wire is filled with vulcanized rubber, screw holes 3 are opened on the connecting ear plates 5 at both ends of the cable mold, and the screws pass through the screw holes to fasten and connect the two-petal cable molds; finally, put the fastened mold into 130 ℃-150℃ oven, take it out after vulcanization for 13-15 hour...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com